A method for dehydration of supplemented hydrogen in szorb device

A technology of hydrogen and air inlet pipes, applied in the direction of hydrogen separation, etc., can solve the problems of limited separation accuracy requirements, long-term operation with large water volume, etc., to achieve maintenance-free equipment, avoid abnormal vibration and excessive current, and reduce short-circuit flow. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the content of the present invention will be further clarified below in conjunction with the embodiments, but the content of the present invention is not limited to the following embodiments.

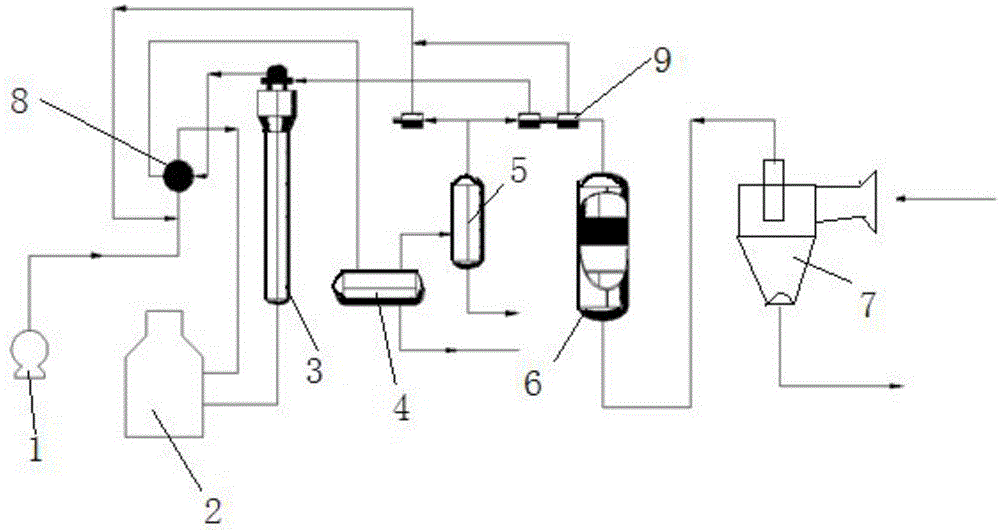

[0047] The method for removing water from the hydrogen supplemented in the Szorb device includes the following steps in sequence:

[0048] A. Under the condition that the pressure is less than 11MPa and the temperature does not exceed 110°C, the supplementary hydrogen is freed from free water to obtain hydrogen with saturated water, and the water content of the hydrogen with saturated water is not more than 50ppm;

[0049] B. Under the condition that the pressure is less than 11MPa and the temperature does not exceed 110°C, the saturated water in the hydrogen entrained with saturated water obtained in step A is removed to obtain purified supplementary hydrogen, and the water content of the purified supplementary hydrogen is not more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com