Coarse titanium tetrachloride vanadium removal device and method

A technology of crude titanium tetrachloride and organic matter, applied in the direction of titanium halide, etc., can solve the problems of easy fouling of equipment, poor vanadium removal effect, affecting heat transfer, etc., and achieve the effect of simple structure, easy maintenance, and reduced erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the crude titanium tetrachloride vanadium removal device and method of the present invention will be described in detail with reference to exemplary embodiments.

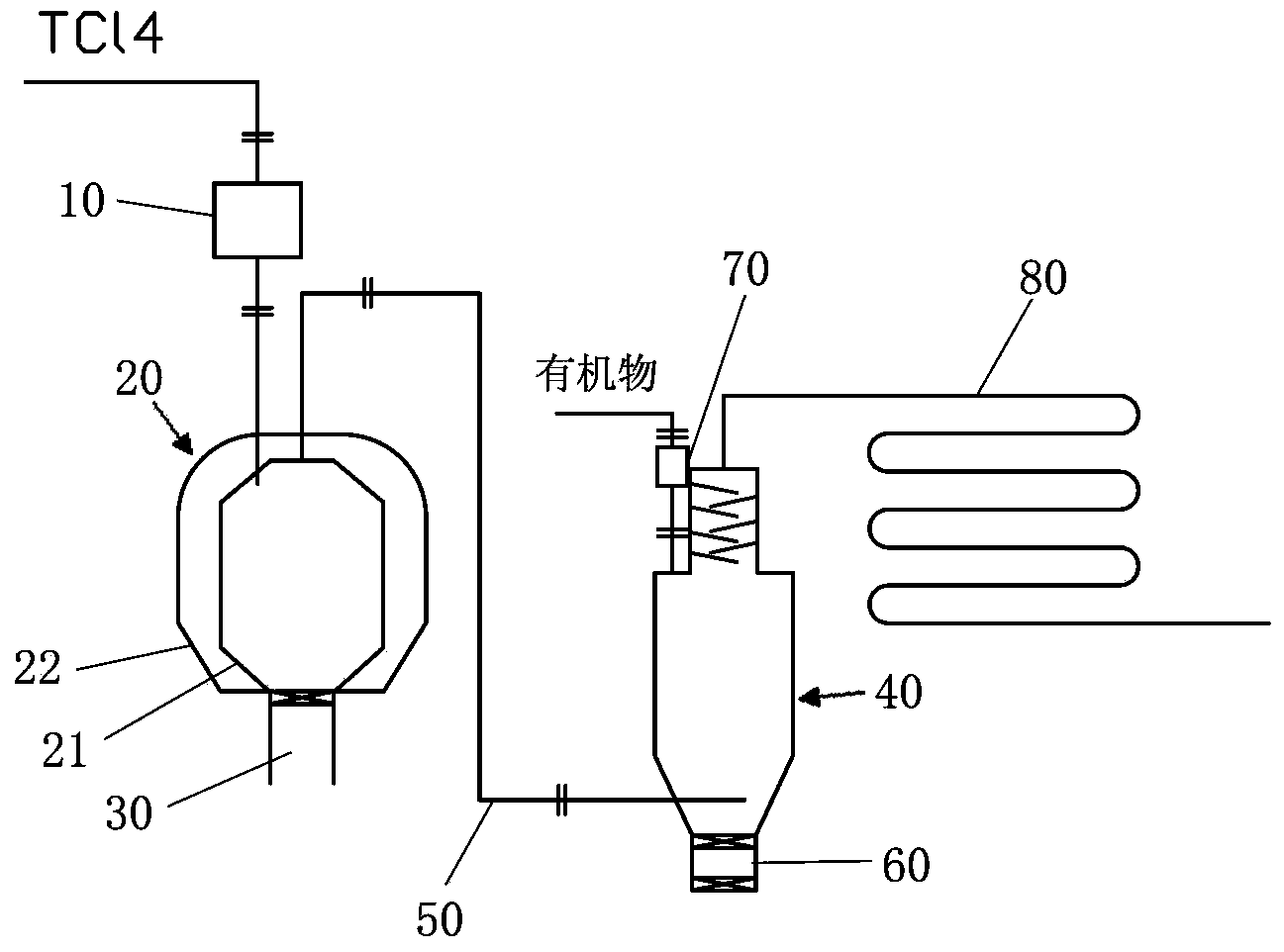

[0028] figure 1 A schematic structural view of a device for removing vanadium from crude titanium tetrachloride according to an exemplary embodiment of the present invention is shown. Such as figure 1 As shown, the crude titanium tetrachloride vanadium removal device according to an exemplary embodiment of the present invention includes a first storage tank 10, a heating tank 20, a discharge unit 30, a reactor 40, a pipeline 50, a slagging unit 60, a second storage tank Tank 70 and condensation collection unit 80 .

[0029] Wherein, the heating kettle 20 comprises: an airtight kettle body 21, a thick titanium tetrachloride feed port leading into the kettle body, a first mixed steam outlet arranged at the top of the kettle body, a discharge port arranged at the bottom of the kettle body, and A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com