Method for preparing tungsten alloy nanomaterials by hot extrusion of cruciform equal channel die cavity

A nanomaterial, cross-shaped technology, applied in the directions of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of reducing labor intensity and widening the bending deformation of channels such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

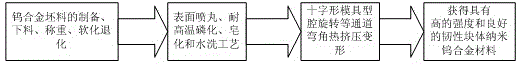

[0019] figure 1 It is a brief illustration of the processing technology of the present invention. 1. Firstly, the cutting and preparation of the tungsten alloy extrusion billet is carried out; 2. The material softening annealing, shot blasting surface treatment process and water washing process; 3. The hot extrusion process is through the cross-shaped mold cavity. Equal channel angle hot extrusion, hot extrusion of difficult-to-deform tungsten alloys, and the repeated plastic deformation of tungsten alloy materials can be realized by continuously rotating the cross-shaped mold. The lubricants used in the extrusion process are molybdenum disulfide and paraffin wax mixture, the mixing ratio is 2:1.

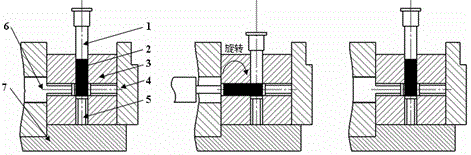

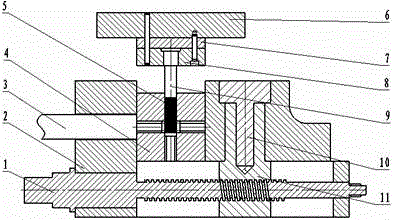

[0020] figure 2 It is a schematic diagram of hot extrusion of cross-shaped mold cavity and other channel angles of the present invention: 1. Initial state: put the processed tungsten alloy billet into the cross-shaped mold cavity; 2. Extrude once: the punch goes down, when the pun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com