Reciprocating extrusion device and processing method for reinforced magnesium alloy tube

A technology for strengthening magnesium alloys and processing methods, applied in metal extrusion dies and other directions, can solve the problems of inability to meet the market demand of magnesium alloy pipes and application restrictions, and achieve the effects of simple structure, low production cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Material preparation: Carry the magnesium alloy ingot to remove the surface layer, process it into a round tube billet with an inner diameter 0.1mm larger than the diameter of the fixed extrusion rod, and an outer diameter 0.1mm smaller than the inner diameter of the extrusion barrel mold, and remove the surface oil, and then put it into 350 ℃ for heating In the furnace, keep warm for 1 hour;

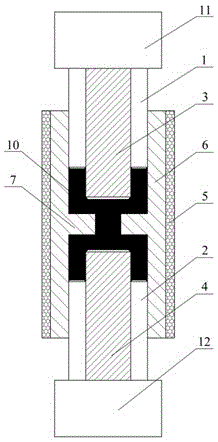

[0038] First install the reciprocating extrusion device on the hydraulic extrusion machine, install it firmly, connect it correctly, and turn on the heating jacket 4 to heat the extrusion die, and keep it warm for 30 minutes when it reaches 350°C.

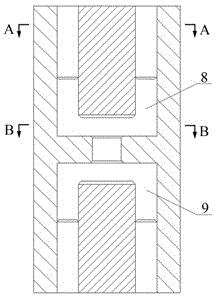

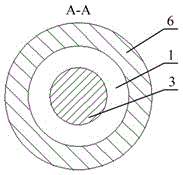

[0039] Then start the hydraulic extrusion machine, withdraw from the upper extrusion ring 1 and the upper fixed extrusion rod 3, place the preheated magnesium alloy pipe blank 10 in the upper die cavity 8 of the extrusion barrel mold 6, and then press the upper extrusion The ring 1 and the upper fixed extrusion rod 3 extend into the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com