Line locking welding and heat treatment integrated operation construction method

A technology of line locking and construction methods, which is applied in the field of rail welding, can solve problems such as endangering traffic safety, and achieve the effects of safe construction, reliable quality, and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

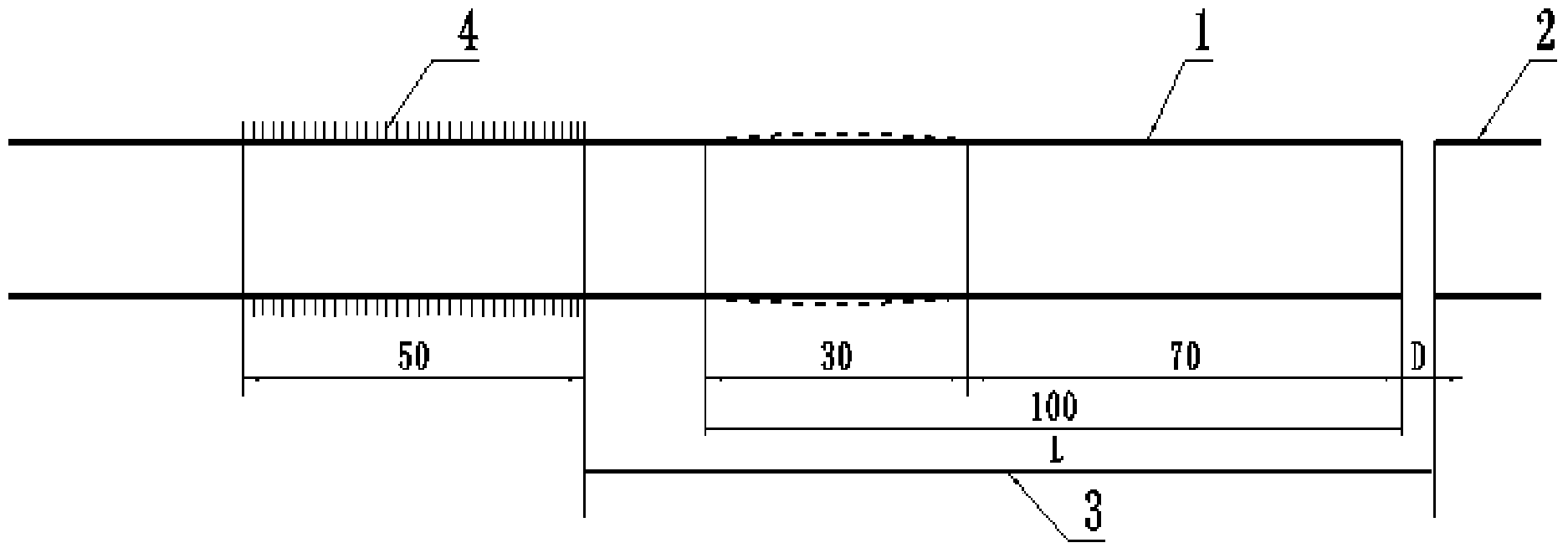

[0043] The present invention will be further described below in conjunction with accompanying drawing:

[0044] 1. Standard working procedures for welding rails: rail sawing, rust removal, end grinding, rail pulling, welding, blast cooling, heat treatment under pressure, straightening, finishing, flaw detection.

[0045] 2. Construction rail temperature: The construction rail temperature is not greater than the design rail temperature. If the construction rail temperature is higher than the design rail temperature, it is necessary to add technical measures for auxiliary cooling.

[0046] 3. On-line locking welding of unit rails not less than 1,000 meters in length is carried out using a pneumatic rail welding car.

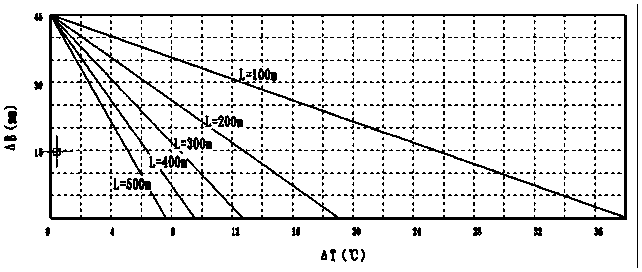

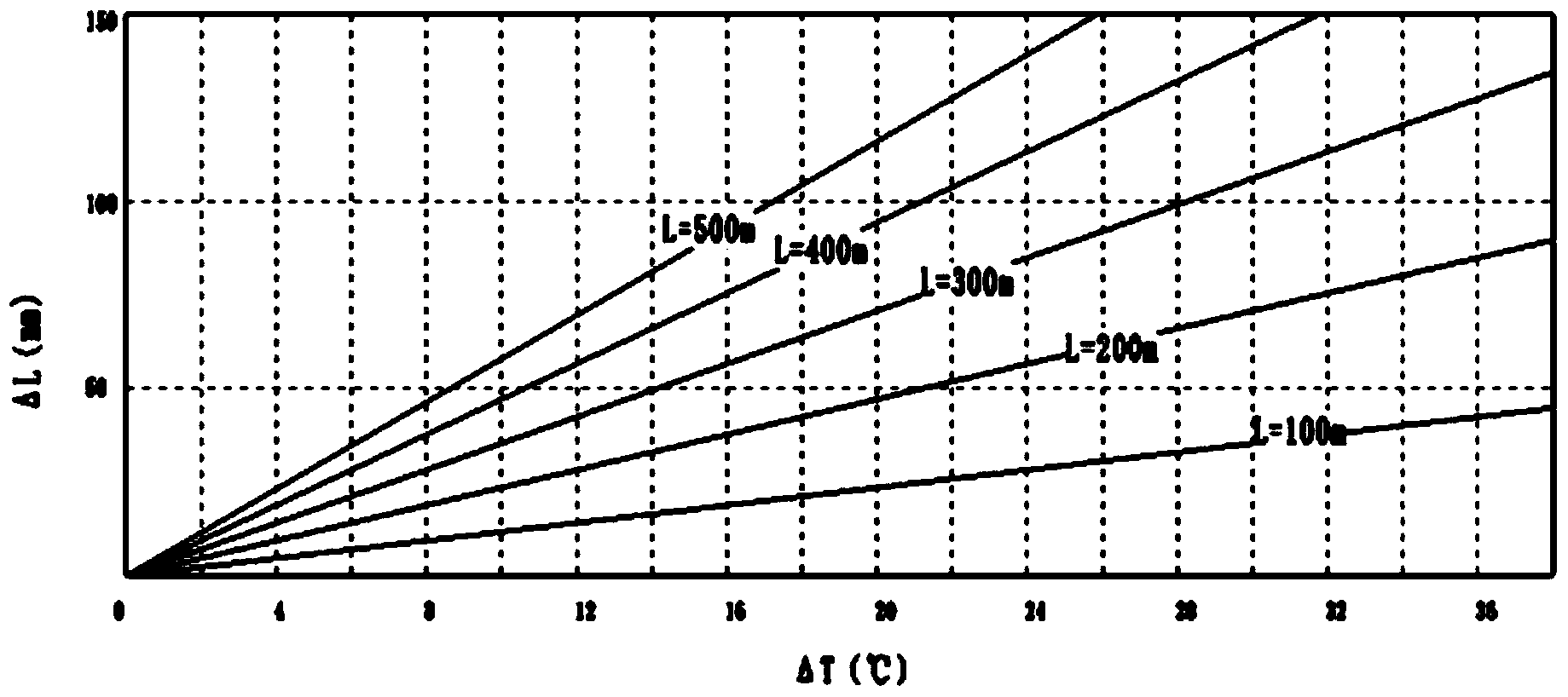

[0047] 4. Determine the length of the construction section of locking welding 3: according to figure 1 For curve and rail temperature difference parameters, it is preferred to select the segment length L range where the bending amount ΔB is equal to 0.

[0048] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com