High-power hydraulic drive fracturing pump system

A fracturing pump, high-power technology, used in pumps, piston pumps, machines/engines, etc., can solve the problem of high road bearing capacity and slope requirements, difficult layout of well site limited space, too many fracturing trucks and pump trucks, etc. problems, to achieve the effect of improving vehicle congestion, small size, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

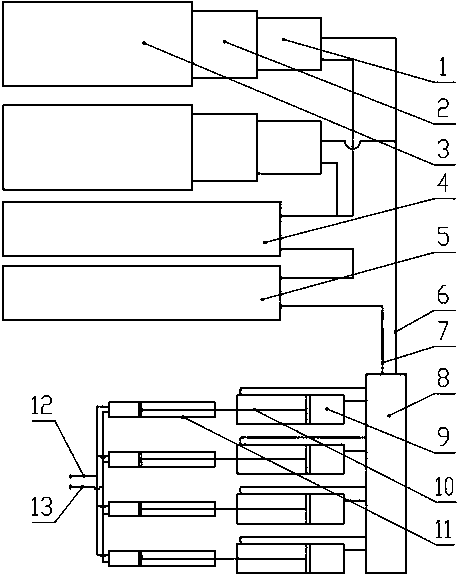

[0009] Combine below figure 1 The present invention is described as follows:

[0010] Such as figure 1 As shown, the fracturing pump cylinder 11 and the power cylinder 9 are connected in series, and the bolts connect the fracturing pump cylinder 11 and the power cylinder 9; the plunger 10 is installed in the fracturing pump cylinder 11, and the end of the plunger 10 is provided with a piston and installed in the power cylinder 9; the fracturing pump cylinder 11 is connected to the fracturing fluid inlet manifold 12 and the fracturing fluid outlet manifold 13; the fluid inlet and discharge port of the power cylinder 9 is connected to the reversing assembly 8, and the reversing assembly 8 is connected to the oil inlet pipe 6 and The oil return pipe 7; the oil inlet pipe 6 is connected to the hydraulic oil pump 1, the oil return pipe 7 is connected to the inlet of the cooler 5, and the outlet of the cooler 5 is connected to the oil tank 4 with a hydraulic pipeline; the oil tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com