Asphalt pavement load temperature coupling testing device and testing method thereof

A technology of asphalt pavement and test device, which is applied in the direction of measuring device, strength characteristics, preparation of test samples, etc., to achieve the effects of good test stability, high test accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

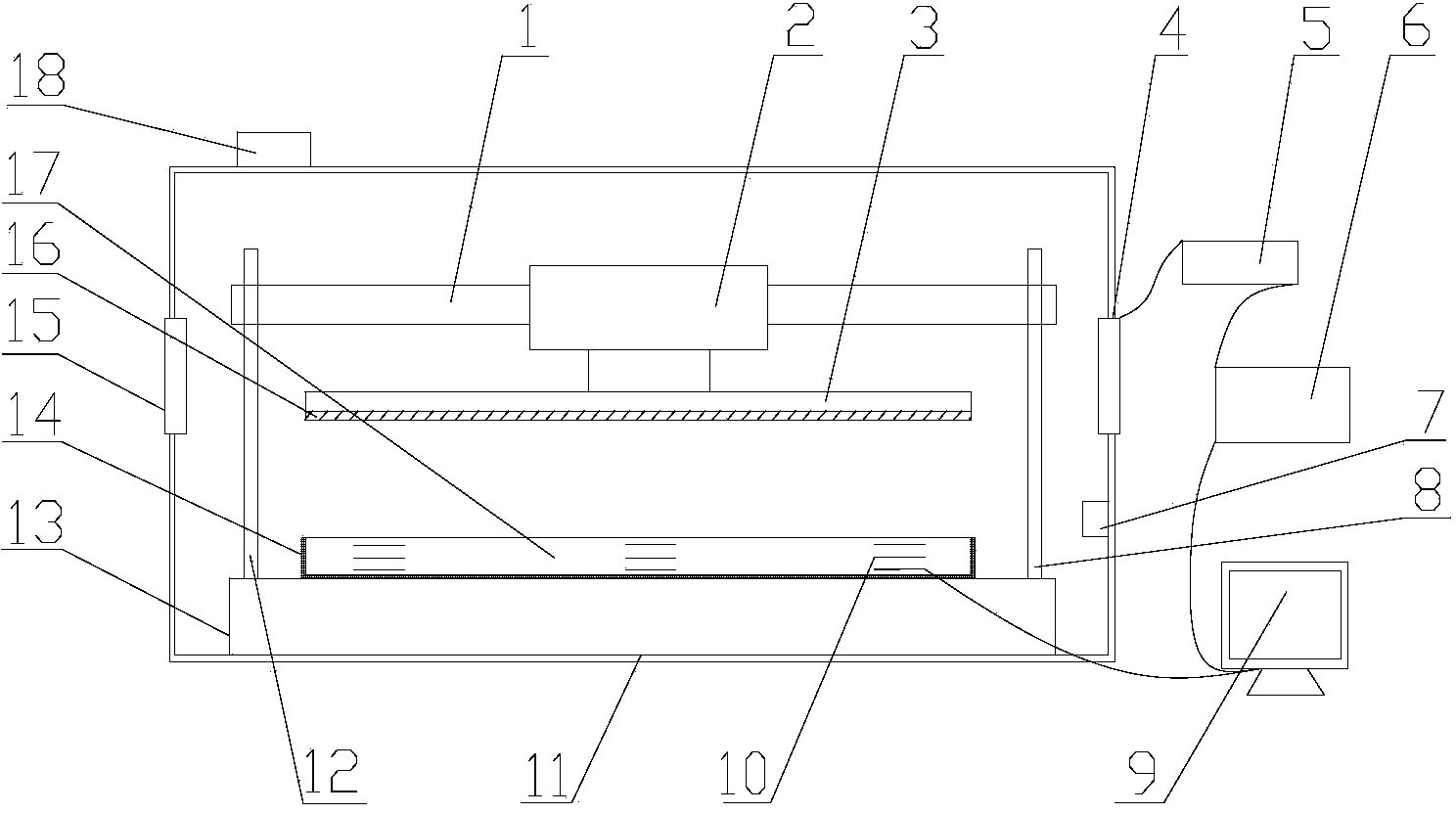

[0037] in figure 1 In this embodiment, the test device for load temperature coupling effect of asphalt pavement is composed of cantilever beam 1, hydraulic cylinder 2, pressure plate 3, air intake fan 4, variable resistor 5, programmable controller 6, electronic thermometer 7, right bracket 8, computer 9. The stress sensor 10, the temperature isolation box 11, the left bracket 12, the test piece table 13, the test piece holding box 14, the exhaust fan 15, the heating plate 16, and the solenoid valve 18 are connected.

[0038] A test piece table 13 is placed at the bottom of the temperature isolation box 11. The left side of the test piece table 13 is fixedly connected with a left bracket 12 with a threaded fastening connector, and the right side of the test piece table 13 is fixedly connected with a threaded fastening connector. Right bracket 8, the left end of the cantilever beam 1 is fixedly connected to the left bracket 12 with a threaded fastening connector, the right end of ...

Embodiment 2

[0064] The test piece container 14 is also placed on the test piece table 13. The test piece container 14 is an open container on the upper surface, and the test piece container 14 is used to place the test piece 17 and 12 stress sensors are laid in the test piece 17 10. The stress sensor 10 is arranged in three layers in the test piece 17 with a layer spacing of 5 cm, 4 in each layer horizontally and 3 vertically, uniformly arranged. The stress sensor 10 is connected to the computer 9 through a wire.

[0065] The other parts and the connection relationship and working principle of the parts are the same as in the first embodiment.

[0066] The method of using the above-mentioned asphalt pavement load-temperature coupling effect test device to carry out the asphalt pavement load-temperature coupling effect test is the same as in Example 1.

Embodiment 3

[0068] The test piece container 14 is also placed on the test piece table 13. The test piece container 14 is an open container on the upper surface. The test piece container 14 is used to place the test piece 17, and 9 stress sensors are laid in the test piece 17 10. The stress sensor 10 is arranged in three layers in the test piece 17 with a layer spacing of 4 cm, each layer is arranged 3 horizontally and 3 longitudinally, uniformly arranged. The stress sensor 10 is connected to the computer 9 through a wire.

[0069] The other parts and the connection relationship and working principle of the parts are the same as in the first embodiment.

[0070] The method of using the above-mentioned asphalt pavement load-temperature coupling effect test device to carry out the asphalt pavement load-temperature coupling effect test is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com