Flexible mineral insulation aluminum conductor fireproof cable

A technology of mineral insulated and fireproof cables, applied in the field of power transmission and distribution, can solve problems such as the inability to meet the requirements of cable fire protection standards, the inability to use aluminum core conductors, the failure of insulation layer insulation, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

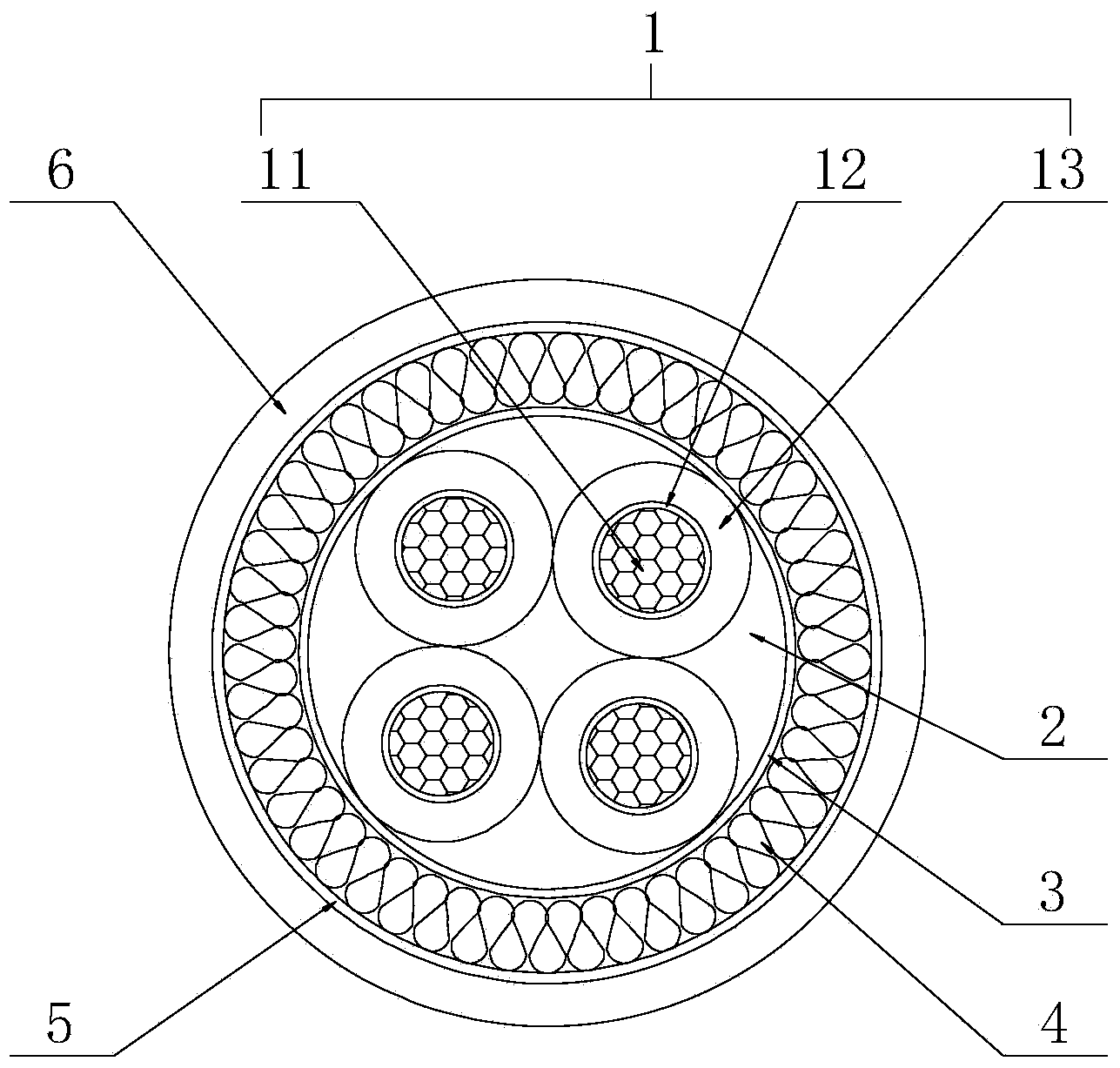

[0018] The following combination figure 1 The given examples further illustrate the specific implementation of the flexible mineral insulated aluminum core fireproof cable of the present invention. The flexible mineral insulated aluminum core fireproof cable of the present invention is not limited to the description of the following embodiments.

[0019] For the convenience of description, the flexible mineral insulated aluminum core fireproof cable of the present invention is figure 1 The cross-sectional schematic diagram of the four aluminum alloy cable cores 1 shown is an embodiment, and it should be understood that there may be one aluminum alloy cable core 1 or multiple aluminum alloy cable cores 1 . The aluminum alloy cable core 1 is suitable for the voltage level of 1kV, and its structure is figure 1 Among them: 1 represents the aluminum alloy cable core, which includes an aluminum core conductor 11, a mineral insulating layer 12 and an insulation strengthening layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com