Connection structure and connection method of chip

A connection structure and connection method technology, applied in the field of electrical connection, can solve problems such as high product cost, unqualified products, and reduced yield, and achieve the effects of improving yield, preventing oxidation and corrosion, and reducing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0021] In order to solve the problems existing in the chip connection structure in the prior art, the technical solution adopted by the present invention is: the chip a2 and the chip b3 are bonded and connected through the bonding wire 4 .

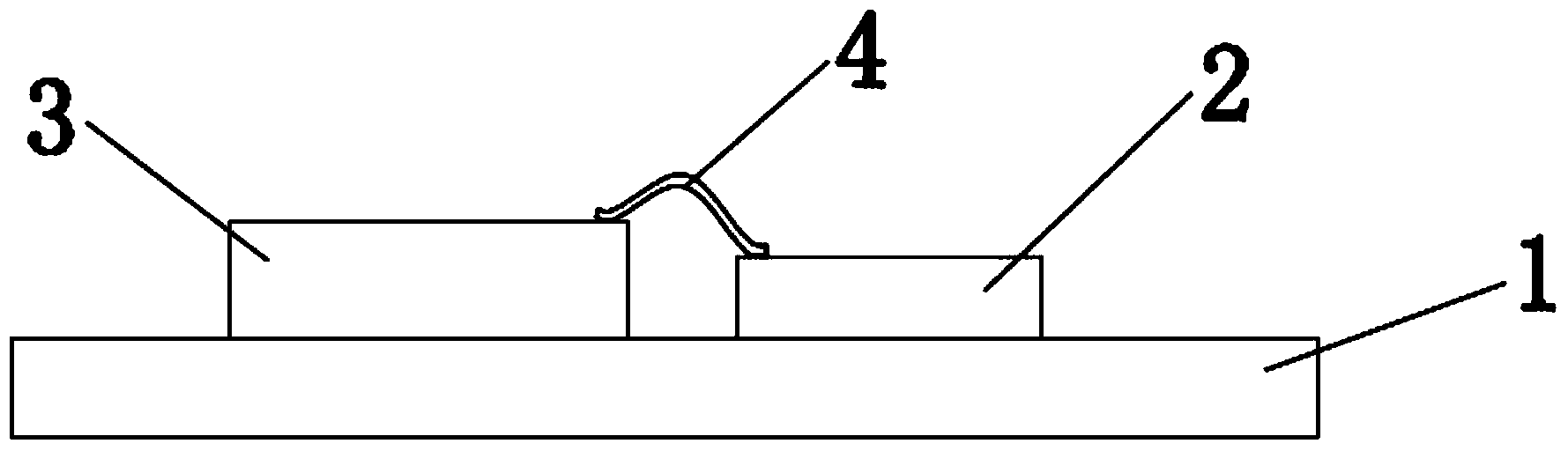

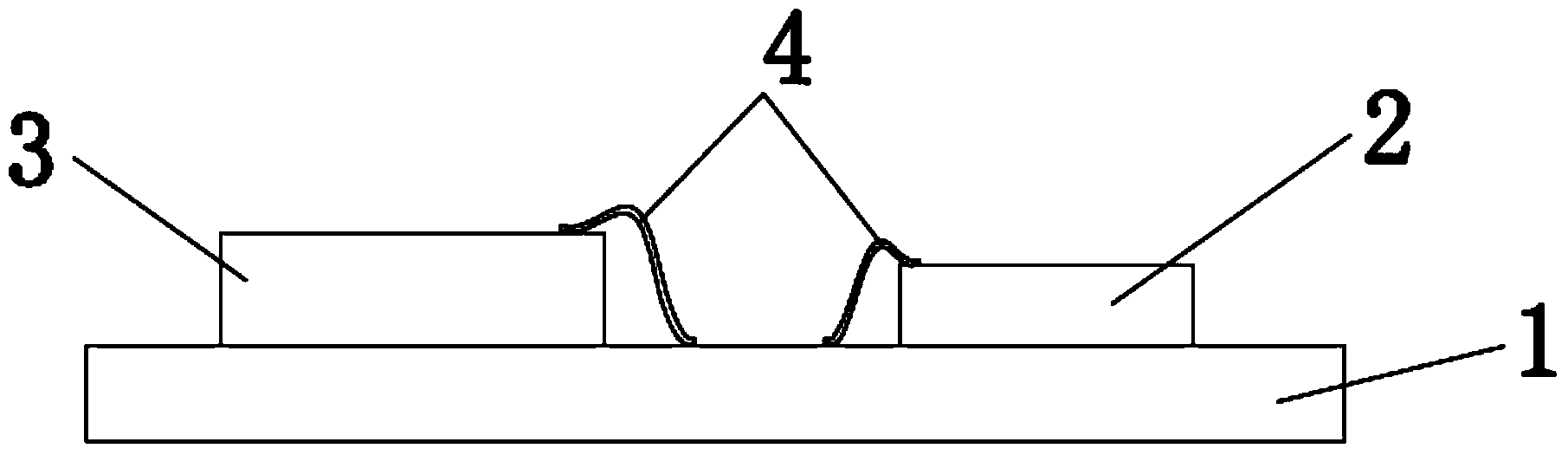

[0022] Such as figure 1 As shown, it is the chip connection structure of the present invention, the chip a2 and the chip b3 are fixed on the circuit board 1, and one end of the bonding wire 4 is pressure-welded to the lead terminal on the electrode surface of the chip a2 through the wire feeding end of the bonding machine to form the second A bonding point is then moved to the position corresponding to the other chip b3 for pressure welding to complete the connection process of the bonding wire 4 .

[0023] Preferably, the bonding wire 4 is a gold wire or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com