Photochromic switching film and method for producing the same

A manufacturing method and conversion film technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve problems such as poor visual effects, uneven output light source uniformity, and failure of point light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

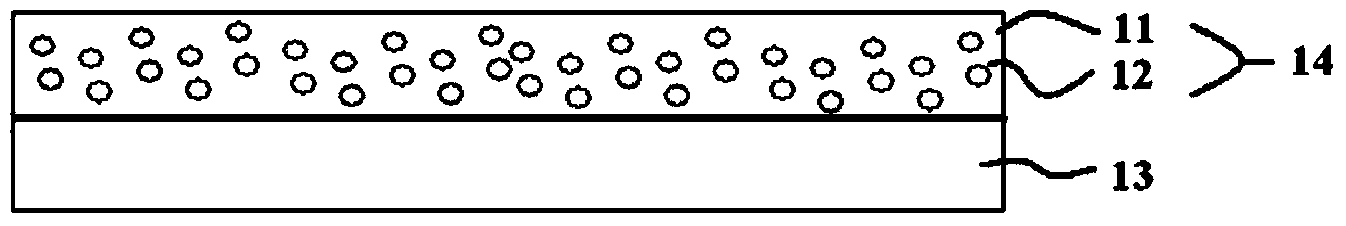

Image

Examples

preparation example 1 to 6

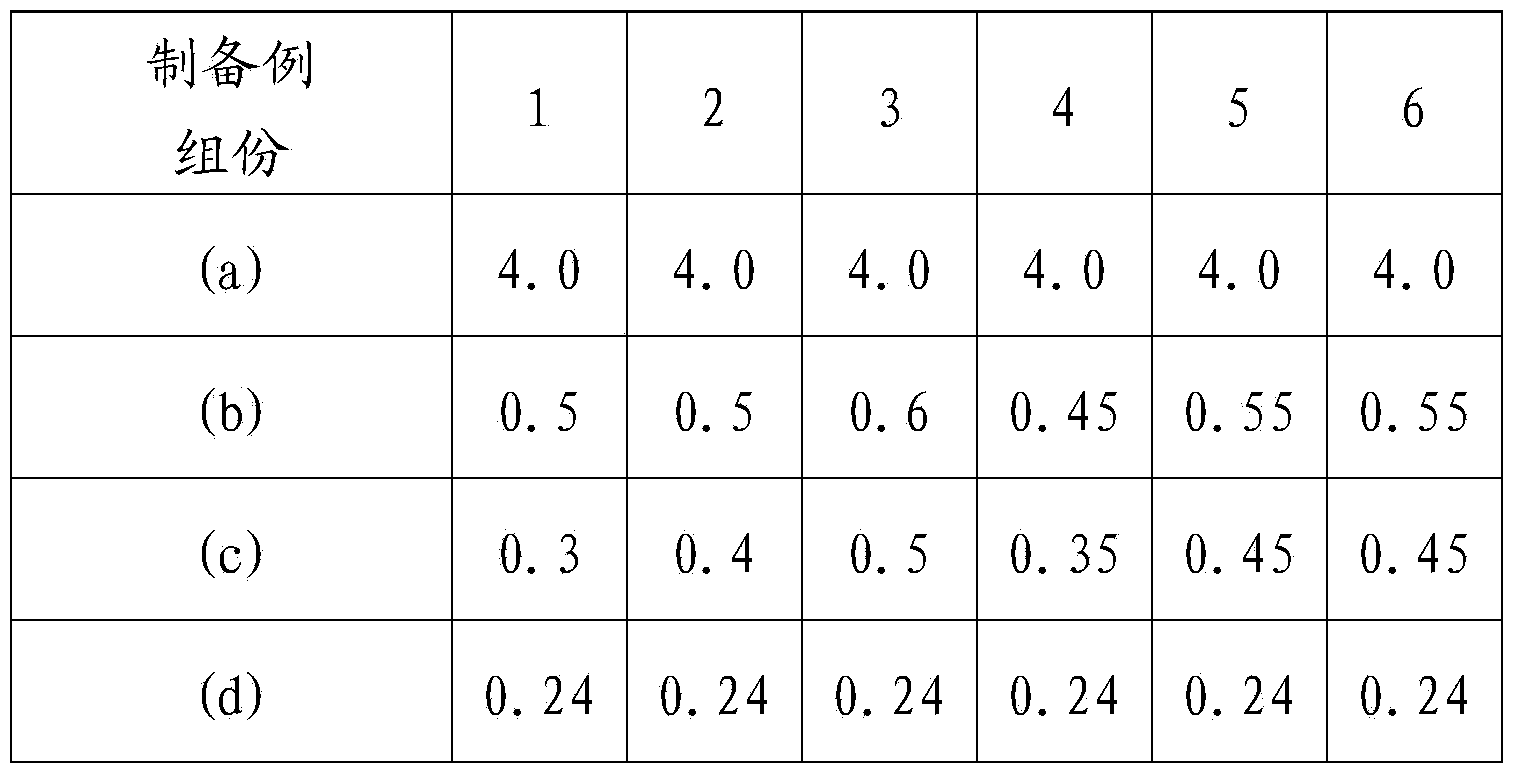

[0070] The light-color conversion layer compositions of Examples 1 to 6 were prepared according to the methods described below, and their compositions are listed in Table 1.

[0071] Firstly, each component was mixed with the weight (grams) listed in Table 1, and stirred at room temperature and in a dark room until completely mixed uniformly to form a photochromic conversion layer composition. Then, at a curing energy of 1500 millijoules / square centimeter (mJ / cm 2 ) conditions, a 100-micron thick photochromic conversion layer was formed on a 500-micron glass substrate (91.4% transmittance).

[0072] Table 1

[0073]

[0074] (a) oligomer and monofunctional monomer mixture: CN966J75 produced by Sartomer Company, which contains 75wt% polyurethane (meth)acrylate and 25wt% monofunctional monomer SR506: isobornyl acrylate .

[0075] (b) Monofunctional monomer: EM219: isodecyl acrylate produced by Changxing Company.

[0076] (c) Monofunctional monomer: EM211: 2-(2-ethoxyethox...

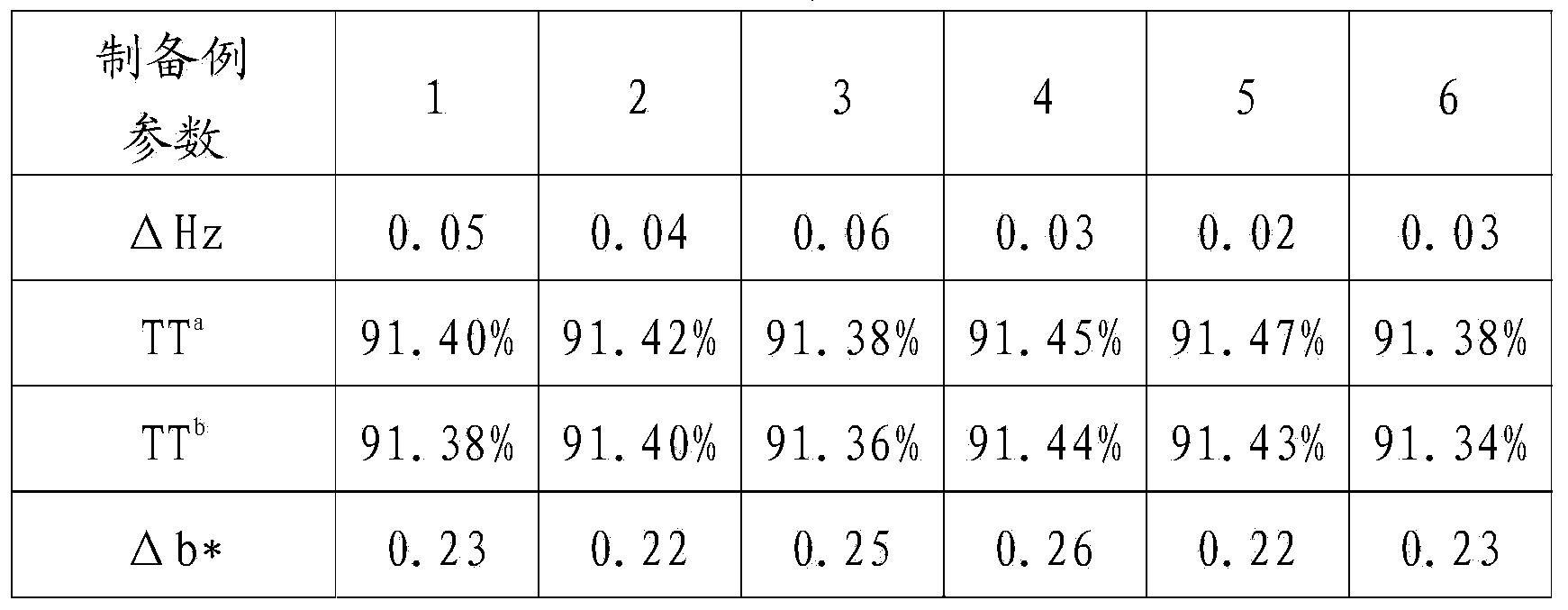

Embodiment 1 to 6 and comparative example 1 and 2

[0089] In the same manner as in Preparation Examples 1 to 6 and as described below, each component was mixed with the weight (grams) listed in Table 3, wherein component (e) was further added to form a glue solution of the light-color conversion layer composition. Then, at a curing energy of 1500 millijoules / square centimeter (mJ / cm 2 ) conditions, a 100-micron thick photochromic conversion layer was formed on a 500-micron glass substrate (91.4% transmittance).

[0090] table 3

[0091]

[0092] The above (a) to (d) are the same as shown in Table 1, and (e) is a yellow phosphor (HSD-86450 produced by Xiongding Technology).

[0093] Test method 2:

[0094] Tensile test: The method of film formation is to uniformly stir the glue solutions of each preparation example and comparative example, after fully dispersing the yellow phosphor, coat it on a 50 micron PET film with a wire bar, and cure it under UV light with a curing energy of 1,500 millijoules / square centimeter(mJ / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com