Filtering type deodorization brick and combining device thereof

A combined device and deodorizing brick technology, which is applied in the fields of environmental protection and waste gas treatment, can solve the problems of inability to change related components and fillers, less processing reports, and inconvenient construction, and achieve low operating costs, convenient and fast construction, and simplified construction The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

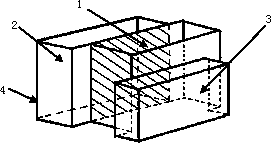

[0034] Such as Figure 1~4 As shown, a filter deodorizing brick, the filler layer 2, the waste iron wire layer 1 and the matrix soil layer 3 are filled in the wire mesh shell 4 in sequence, and the three layers are equal in length, but they are arranged in random order when installed, and the middle waste iron wire layer 1 is at one end. protruding, the other end is recessed, and the end of the same side of the waste iron wire layer 1 and the matrix soil layer 3 are on the same vertical plane.

[0035] The filler layer 2 is made of natural porous stone inoculated with microorganisms, which can absorb and degrade amine substances.

[0036] Scrap iron wire layer 1 can be quickly combined with H 2 The S gas reacts, and the salts produced can be absorbed by the vegetation 7 as nutrients of the matrix soil layer 3 .

[0037] The matrix soil layer 3 can be as high as the filler layer 2, or can be lower than the filler layer 2. Vegetation 7 can be planted on the matrix soil layer 3...

Embodiment 2

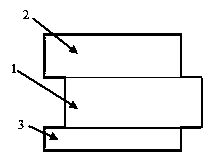

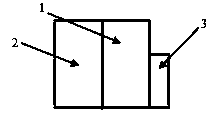

[0040] Such as Figure 5~7 As shown, a combination device of filter deodorizing bricks, the concave end of filter deodorizing brick 8 is interspersed with the protruding end of another same filtering deodorizing brick 8, and installed on the steel support frame layer by layer 6, the steel support frame 6 is used as the foundation of the wall and the ceiling, and the top is spliced by filtering deodorizing bricks 8 with the matrix soil layer 3 and the filler layer 2 at the same height, and the side walls are made of the matrix soil layer 3 lower than the filler layer 2. Filtering deodorizing bricks 8 are spliced together.

[0041] The top of the steel support frame 6 is provided with a sprinkler water supply system 5 for watering the vegetation 7 .

[0042] The sprinkler water supply system 5 is provided with a rotary sprinkler head 10 .

[0043] The bottom of the steel support frame 6 is provided with a drainage system 9 and a water pump. The leached water is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com