An external circulation photochemical reaction equipment

A technology of photochemical reaction and external circulation, applied in the direction of chemical/physical/physicochemical processes of energy application, can solve the problems of large solvent emission loss, harsh working environment, high light source temperature, etc., to reduce the energy loss of bubbles, Reduced solvent consumption, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

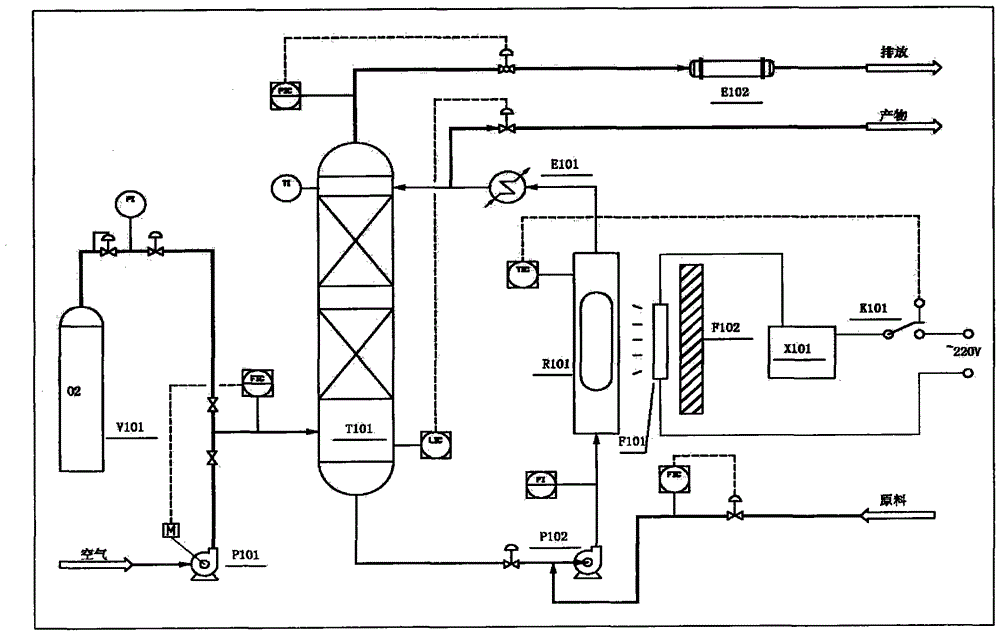

[0011] Combine below figure 1 The external circulation type photochemical reaction equipment is described in detail to further understand the present invention, but the following examples are not limitations of the present invention.

[0012] The 20L reaction liquid is injected into the photochemical reactor R101 by the continuous feeding method of 1.25L / hr. The external light source F101 is reflected by the F102 reflector and enters the reactor from the pressure-resistant window on the plane side of R101, which is the photochemical reaction. provide energy. The intensity of the external light source is adjusted by the temperature control X101 according to the reaction requirements. Oxygen enters the oxygen enrichment tower T101 through the air compressor P101, and enters the photochemical reactor through the circulation pump P102 to participate in the photochemical reaction. Among them, a part of the reacted feed liquid in the reactor is collected as a product through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com