Photo-catalytic reactor and preparation method thereof, based on three-dimensional cylindrical hierarchical structure array

A photocatalytic reactor and cross-scale technology, applied in the field of photocatalysis, can solve the problems of improved catalytic effect and limited catalytic area, and achieve the effects of low production cost, increased surface area, and guaranteed precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

[0031] The preparation method of the present invention is as follows:

[0032] 1) Take multiple dual-mode fibers with a length of 20mm, soak them in acetone for 15 minutes, and extract the fiber core with a diameter of Φ125μm from the fiber plastic cladding;

[0033] 2) Ultrasonic cleaning of multiple fiber cores with absolute alcohol and deionized water for 5 minutes;

[0034] 3) Prepare PDMS solution according to the mass ratio of PDMS and curing agent of 10:1;

[0035] 4) The 25mm×25mm×1mm glass substrate 1 was ultrasonically cleaned with absolute alcohol and deionized water for 5 minutes, and then dried at room temperature;

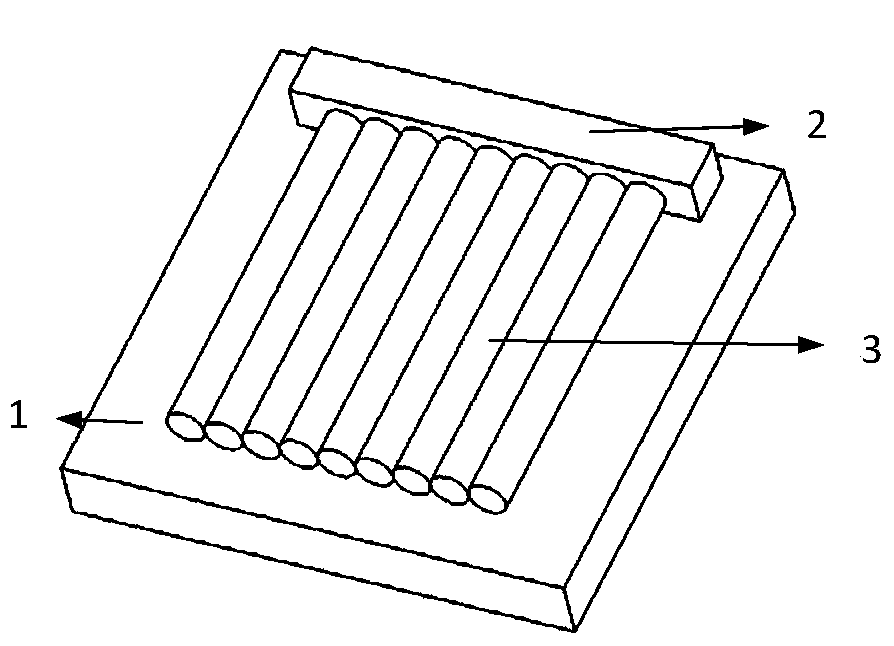

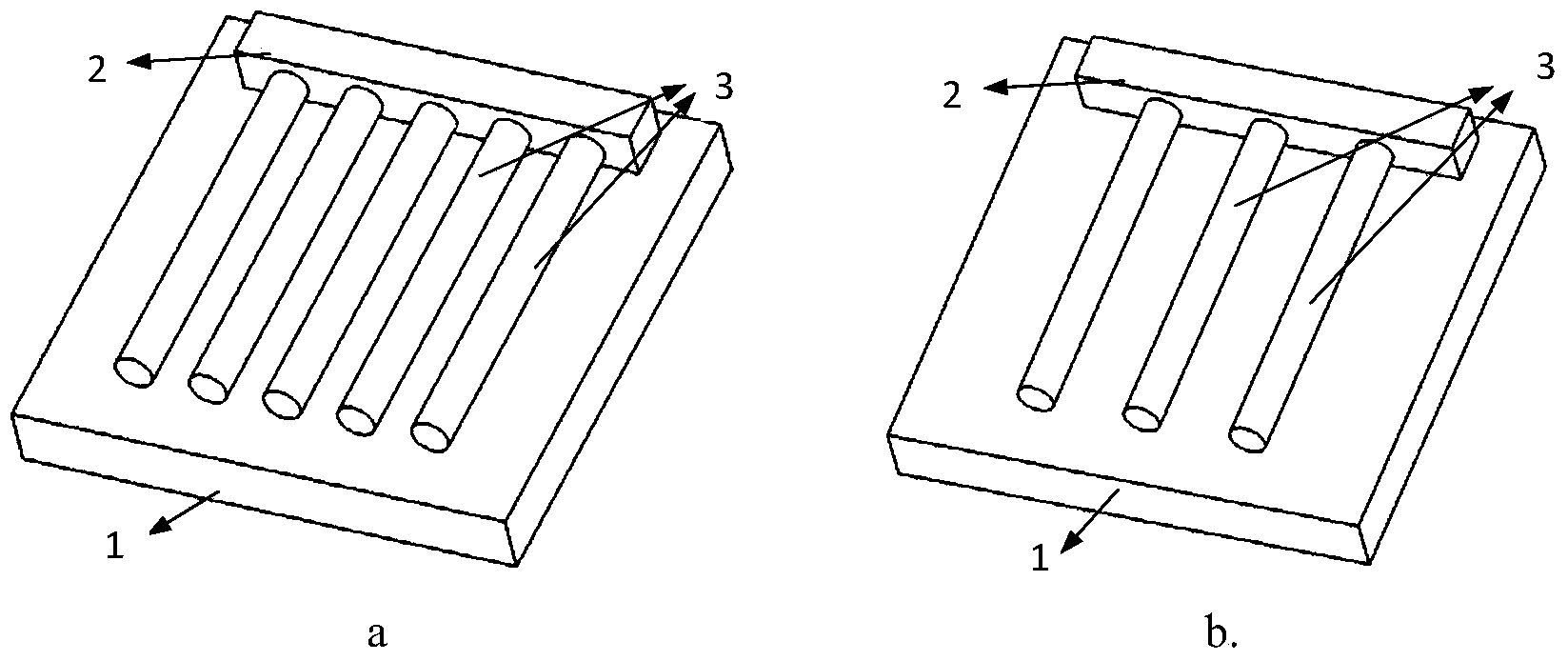

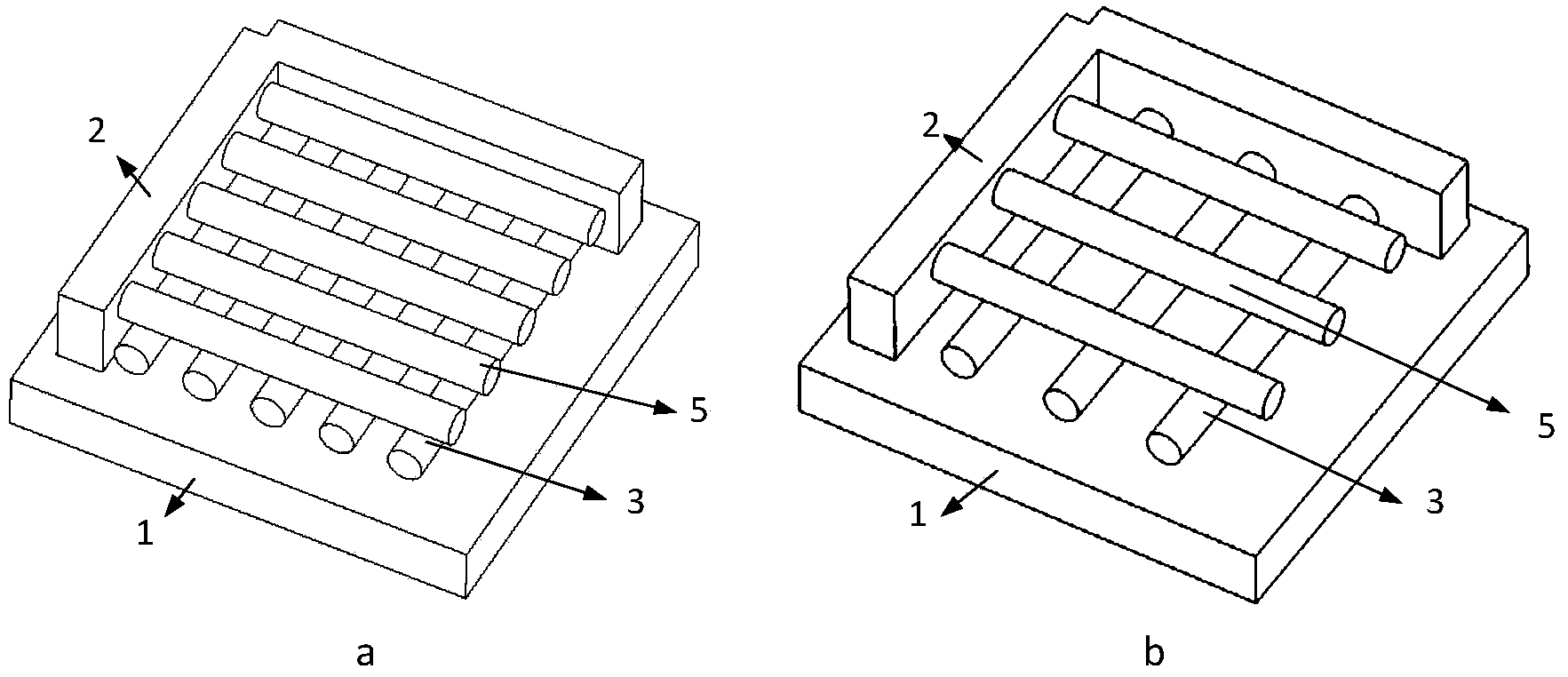

[0036] 5) Manually arrange multiple optical fiber cores tightly on the glass substrate 1, and drop PDMS solution on one end of it, and wait for it to solidify into PDMS glue 2, thereby fixing one end of the closely arranged multiple optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com