Manufacturing method of UOE (uing-oing-expanding) straight seam steel pipe expanded taper

A technology of steel pipe diameter expansion and manufacturing method, which is applied in the manufacturing field of UOE straight seam steel pipe diameter expansion cone, can solve the problems of low processing efficiency, complex processing technology, inconvenient processing, etc., so as to reduce production costs, simplify processing technology, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

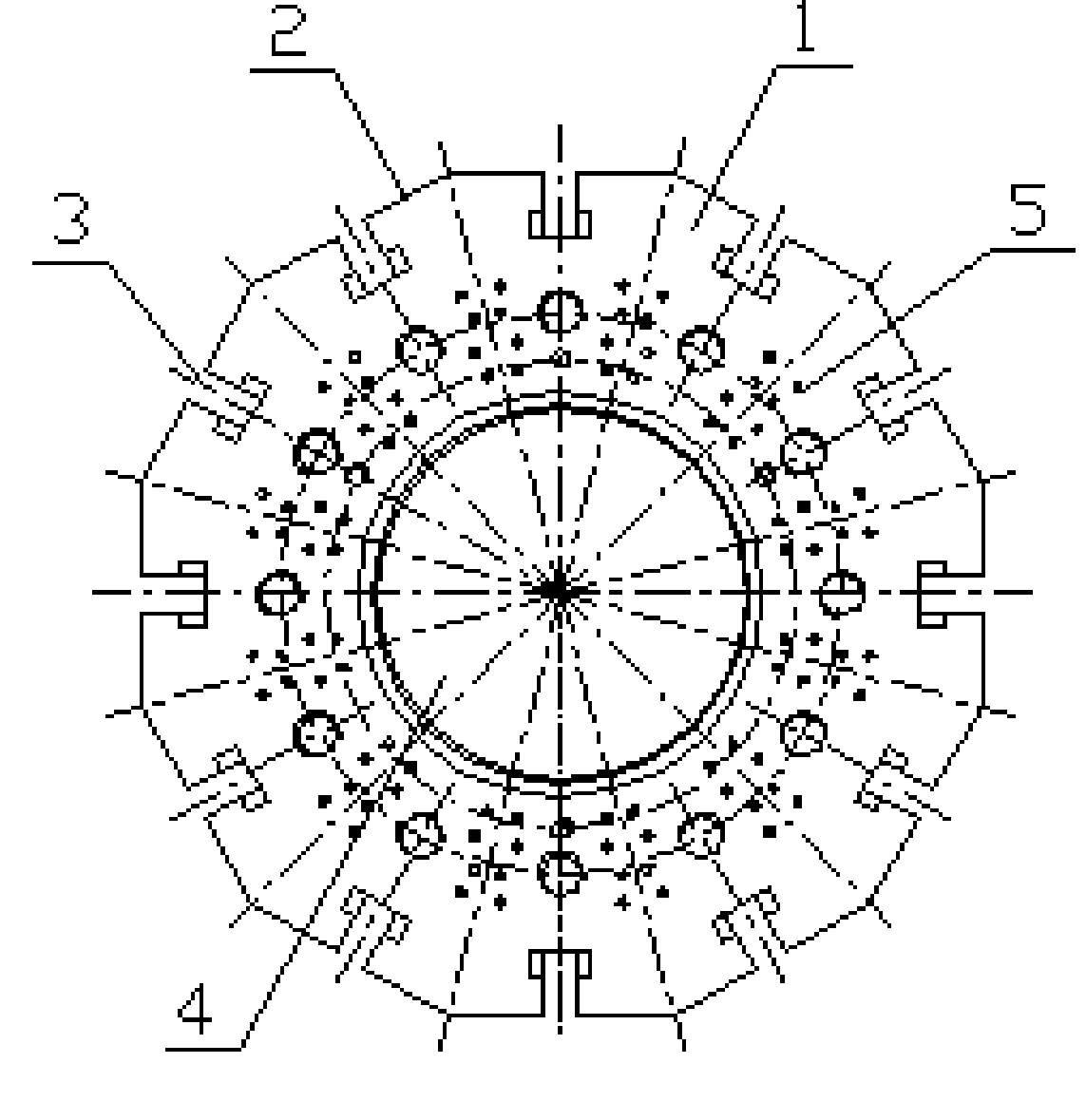

[0022] like figure 1 , figure 2 and image 3 As shown, the manufacturing method of the UOE straight seam steel pipe expanding cone of the present invention comprises the following steps:

[0023] In step 1, the hot work die steel forging is used as the material of the expanded cone body 1, the forging blank is forged by refining and vacuum degassing process, the forging is forged in three directions, the forging ratio is greater than or equal to 5, the forging meets the requirements of ultrasonic flaw detection level II, and the forging is carried out. Post spheroidizing annealing heat treatment;

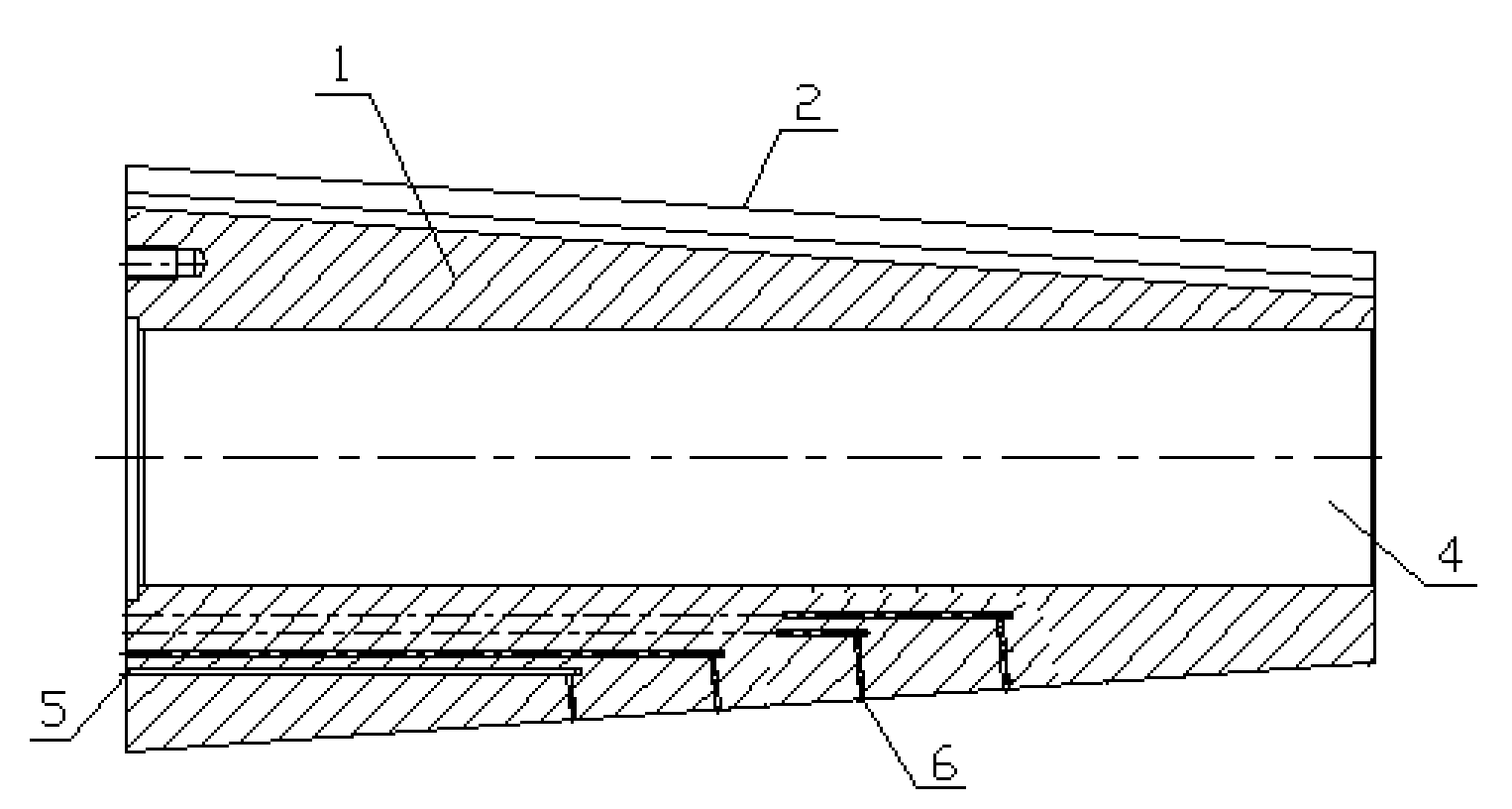

[0024] Step 2, using the boring and milling process to process the inner stepped inner hole 4 of the center of the expanding cone body 1 and turning and milling the end circles at both ends, and the shape of the expanding diameter cone body 1 is processed into a conical circle;

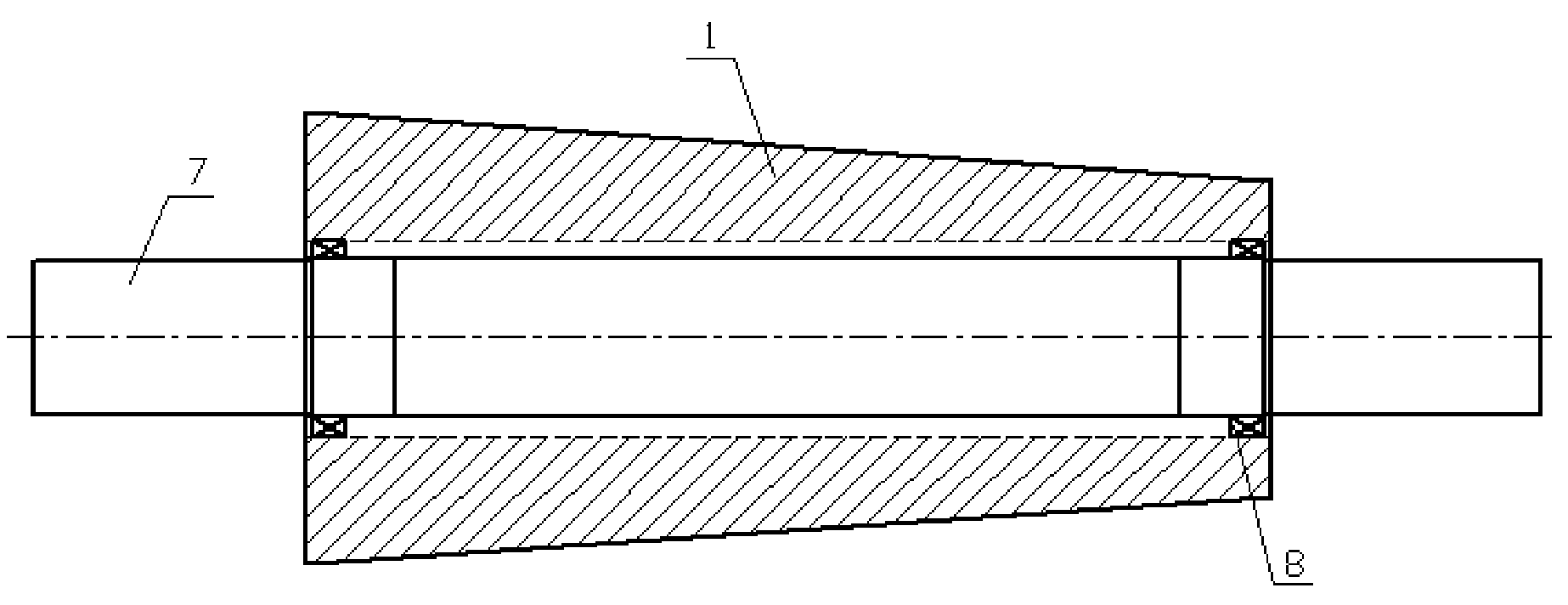

[0025] Step 3: Insert the mandrel 7 into the central inner hole 4 of the diameter-expanding cone bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com