Processing method of large sprocket of automobile engine

A technology of an automobile engine and a processing method, which is applied in the processing field of the large sprocket of an automobile engine, can solve the problems of high cost, deformation and complexity, and achieves the effects of stable grinding amount, reduced allowance and stable flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, the content of the invention of the present invention is described further:

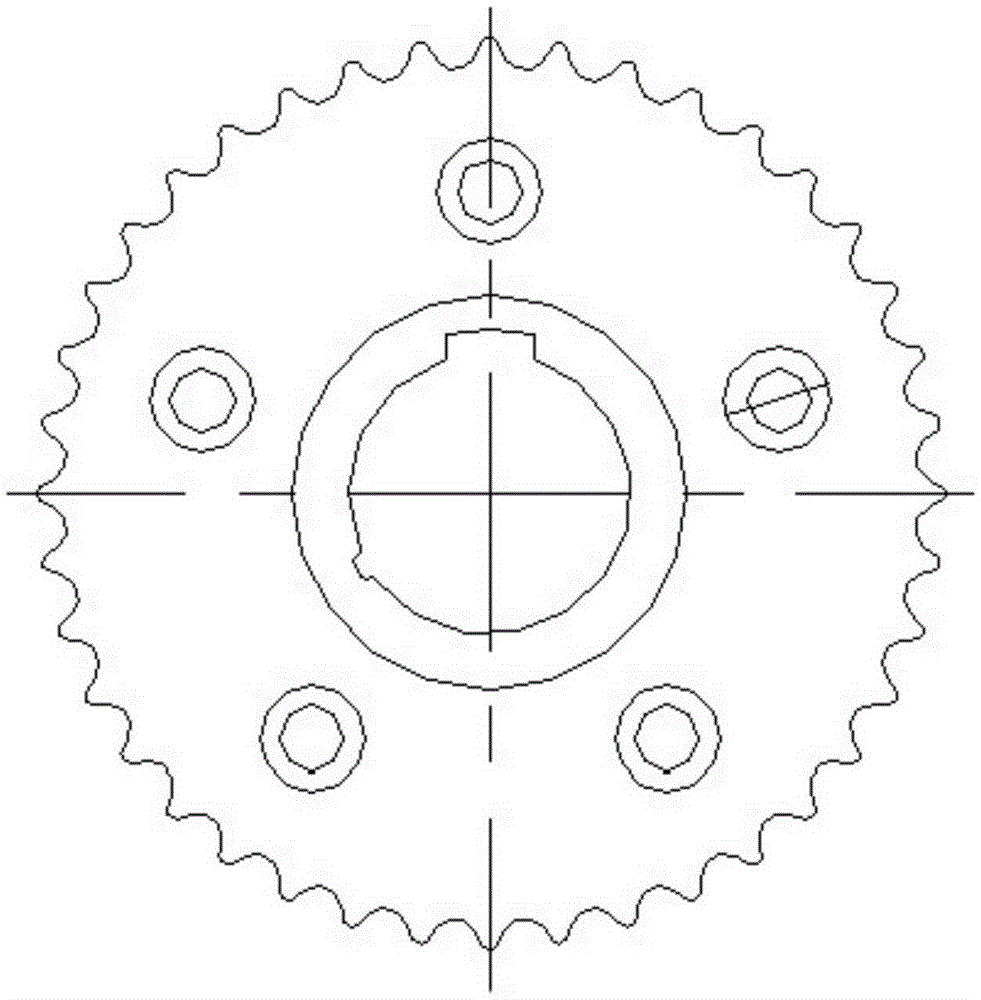

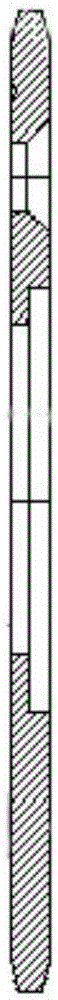

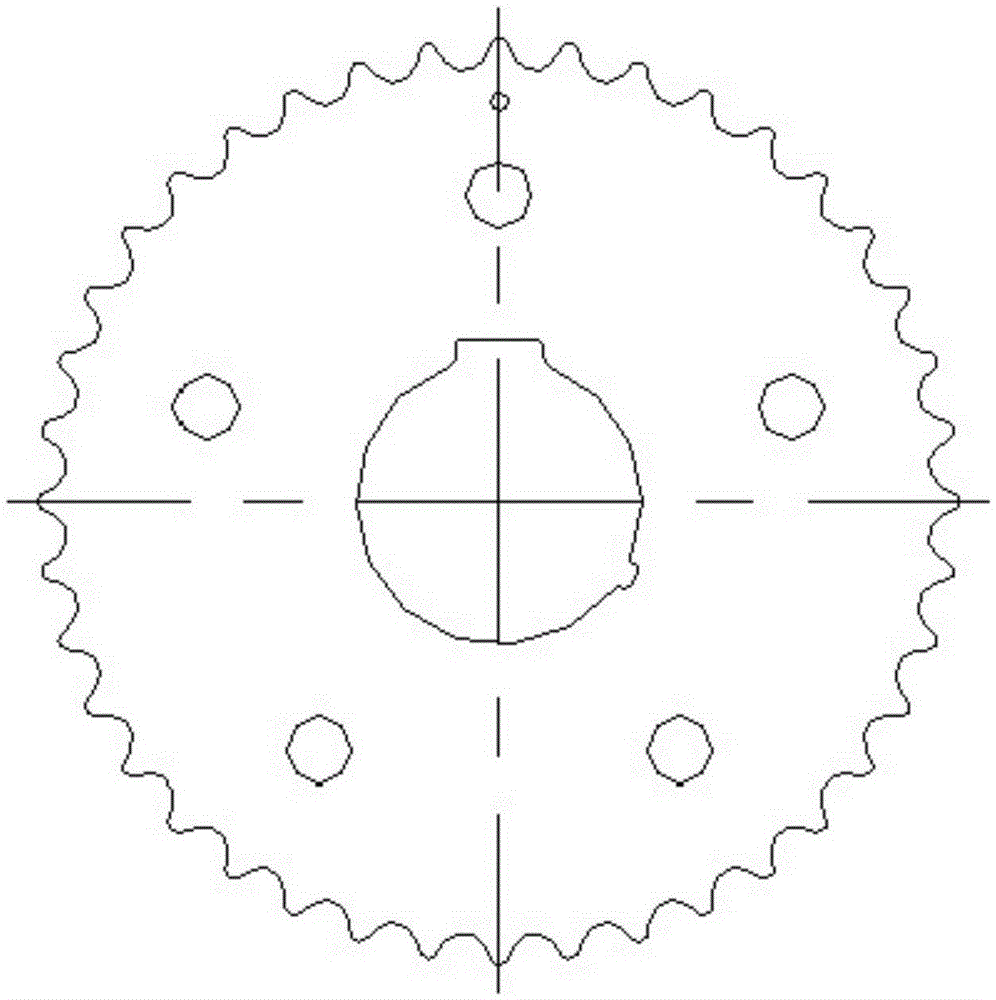

[0033] Such as figure 1 figure 2 image 3 The processing method of the shown parts includes the following steps:

[0034] Use the uncoiling straightening machine to uncoil and straighten the raw material steel plate, and then use the fine blanking machine to fine blank the raw material steel plate to form a plurality of tapered holes in the circumferential direction and a shaft hole in the center (a shaft hole for matching with the shaft) Special-shaped holes), parts with tooth shape;

[0035] Check whether there are hard scratches on the surface of the parts, and then sort out the scratch-free products and clean them to ensure that there are no residual water droplets, no rust and fine-blanking oil;

[0036] Put the parts into the double-end surface grinder for rough surface grinding. After rough grinding, the thickness and size of the parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com