A process method for laser additive manufacturing of crniv series low alloy steel

A low-alloy steel, laser additive technology, applied in the field of laser 3D printing, can solve the problems of complex production process, high processing cost and long cycle of nuclear power emergency diesel engine camshaft, and achieve high material utilization rate, improve mechanical properties, process flow and so on. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

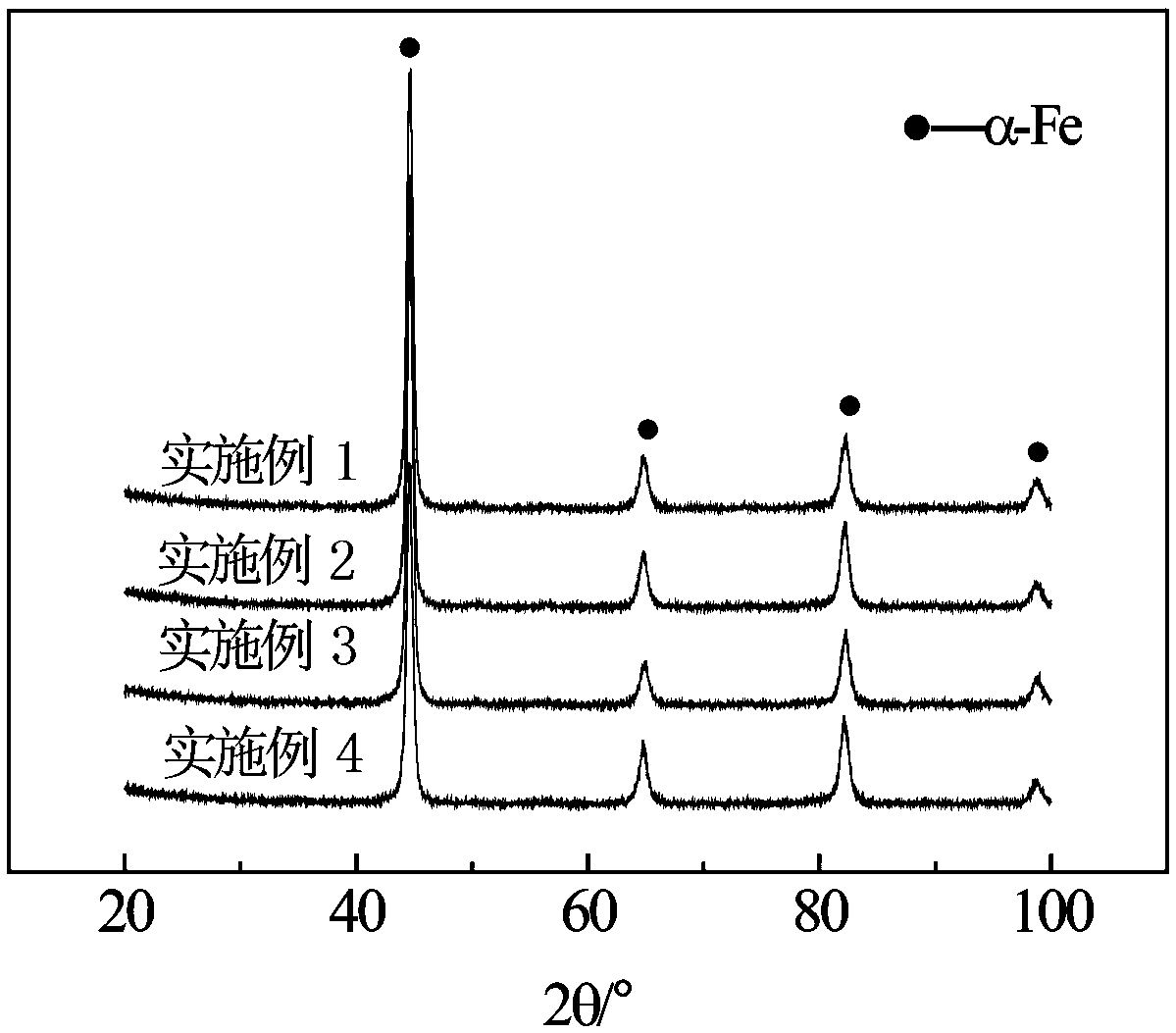

Embodiment 1

[0039] The basic composition weight percent (wt%) of low alloy steel powder is C: 0.05, Cr: 1.40, Ni: 1.80, B: 0.50, Si: 1.00, Mo: 0.50, Mn: 0.10, V: 0.50, and the rest is Fe . The particle size of the powder is 53-140 microns.

[0040] The manufacturing method steps of laser additive manufacturing CrNiV alloy steel are as follows:

[0041]1) the low-alloy steel raw material listed in embodiment 1 is processed through vacuum smelting, gas atomization and sieving procedures to obtain spherical powder; its happy ball rate≤2%, oxygen content≤250ppm; the spherical powder obtained can Reuse more than 3 times, fluidity ≤ 16s / 50g; bulk density ≥ 4.35g / cm 3 .

[0042] 2) Dry the powder obtained in step 1 in an oven at 80°C for more than 3 hours.

[0043] 3) The surface of the low-alloy steel substrate is polished with 60#-500# sandpaper, cleaned and dried for later use, and the powder obtained after drying in step 2 is irradiated with laser beams by means of coaxial powder feeding...

Embodiment 2

[0047] The basic composition weight percentage (wt%) of low alloy steel powder is C: 0.10, Cr: 1.50, Ni: 1.90, B: 0.60, Si: 1.10, Mo: 0.55, Mn: 0.20, V: 0.50, and the rest is Fe . The particle size of the powder is 53-140 microns.

[0048] The manufacturing method steps of laser additive manufacturing low alloy steel are as follows:

[0049] 1) The low-alloy steel raw material listed in embodiment 2 is through vacuum smelting, gas atomization and sieving process, makes spherical powder; Its happy spherical rate≤2%, oxygen content≤250ppm; The spherical powder that makes can repeat Used more than 3 times, fluidity ≤ 16s / 50g; bulk density ≥ 4.35g / cm 3 .

[0050] 2) Dry the powder obtained in step 1 in an oven at 100°C for more than 3 hours.

[0051] 3) The surface of the low-alloy steel substrate is polished with 60#-500# sandpaper, cleaned and dried for later use, and the powder obtained after drying in step 2 is melted and deposited on the surface of the low-alloy steel sub...

Embodiment 3

[0055] The basic composition weight percentage (wt%) of low alloy steel powder is C: 0.18, Cr: 1.60, Ni: 2.00, B: 0.80, Si: 1.20, Mo: 0.55, Mn: 0.40, V: 0.60, and the rest is Fe . The particle size of the powder is 53-140 microns.

[0056] The manufacturing method steps of laser additive manufacturing low alloy steel are as follows:

[0057] 1) the low-alloy steel raw material listed in embodiment 3 is processed through vacuum smelting, gas atomization and sieving procedures, and the spherical powder is obtained; its happy ball rate≤2%, oxygen content≤250ppm; the spherical powder obtained can Reuse more than 3 times, fluidity ≤ 16s / 50g; bulk density ≥ 4.35g / cm 3 .

[0058] 2) Dry the powder obtained in step 1 in an oven at 110°C for more than 3 hours.

[0059] 3) The surface of the low-alloy steel substrate is polished with 60#-500# sandpaper, cleaned and dried for later use, and the powder obtained after drying in step 2 is melted and deposited on the surface of the low-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com