A kind of cemented carbide composite forming method

A cemented carbide and composite forming technology, applied in the field of material forming, can solve the problems of inaccessible net forming of parts and complex shape cavity, and achieve the effect of low processing cost, small processing allowance and convenient forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

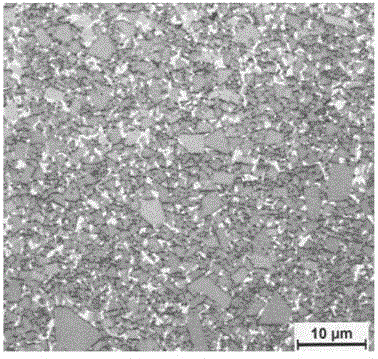

Image

Examples

Embodiment 1

[0033] The cemented carbide composite molding method provided by the invention comprises the following steps:

[0034] S1. Preparation of the mixture: mixing binder, molding agent, and cemented carbide raw material particles with different particle sizes to form a mixture;

[0035] S2. Combined mold design: According to the shrinkage coefficient of the product, use the mold design tool to design the combined mold. The combined mold includes the lower runner mold, the inner concave cavity mold, the cavity disappearing mold and the upper covering mold;

[0036] S3. One-time extrusion molding: inject the mixture into the mold cavity of the lower runner mold and the inner concave cavity mold, and then extrude the mixture after induction heating from bottom to top to form the bottom runner and concave cavity;

[0037] S4. Secondary extrusion molding: After cooling and decompressing the lower runner mold and the inner concave cavity mold, put it into the cavity disappearing mold and...

Embodiment 2

[0045] Preferably, the above-mentioned embodiment 1 of the present invention may also include step S6 between steps S1 and S2, smelting, rolling and crushing of the mixture: heating the mixture into a viscous state, rolling, and then crushing, specifically, The mixture is heated in sections at a heating temperature of 120°C to 160°C. After heating, the mixture becomes viscous, and the viscous mixture is rolled to make the thickness reach 0.15-0.2mm. Repeat 2-4 times. And then broken. This can eliminate the bubbles caused by the expansion of the molding agent when the raw materials are mixed, improve the solid density of the mixture, and ensure that the subsequent injection of the mixture is more uniform and the filling is more compact.

[0046] Specifically, in the above-mentioned embodiment 1, in step S2, three-dimensional three-dimensional software is used to design the combined mold, and through analog analysis and finite element analysis, the design scheme of the optimal p...

Embodiment 3

[0050] Preferably, the above embodiment 1 or embodiment 2 of the present invention further includes step S7 between steps S4 and S5,

[0051] S7. Removal of forming agent: degumming and degreasing the green body obtained in step S4, so as to remove the forming agent in the green body and make the mold cavity in the green body disappear.

[0052] Specifically, the step S7 includes steps S71 and S72,

[0053] S71. Low-temperature degumming: Soak the green body in gasoline at 70-90°C for 28 hours. Of course, the soaking time can be between 25 hours and 30 hours. This low-temperature soaking method can remove 2%~ of the total amount of molding agent. 2.5%;

[0054] S72. High-temperature degreasing: put the green body soaked in gasoline into a vacuum degreasing furnace, raise the temperature in the first section to above 400°C, and keep it warm for 15 minutes. Cooling out of the oven, the remaining molding agent in the product body is completely removed.

[0055] Preferably, in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com