Hole forming device capable of adjusting aperture of formed hole on line

A hole-making device and hole-diameter technology, applied in the field of automatic hole-making, can solve the problems of reduced stability and safety, low hole-making efficiency, slow chip removal, etc., so as to improve stability and safety and improve hole-making efficiency. , to avoid the effect of cable entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

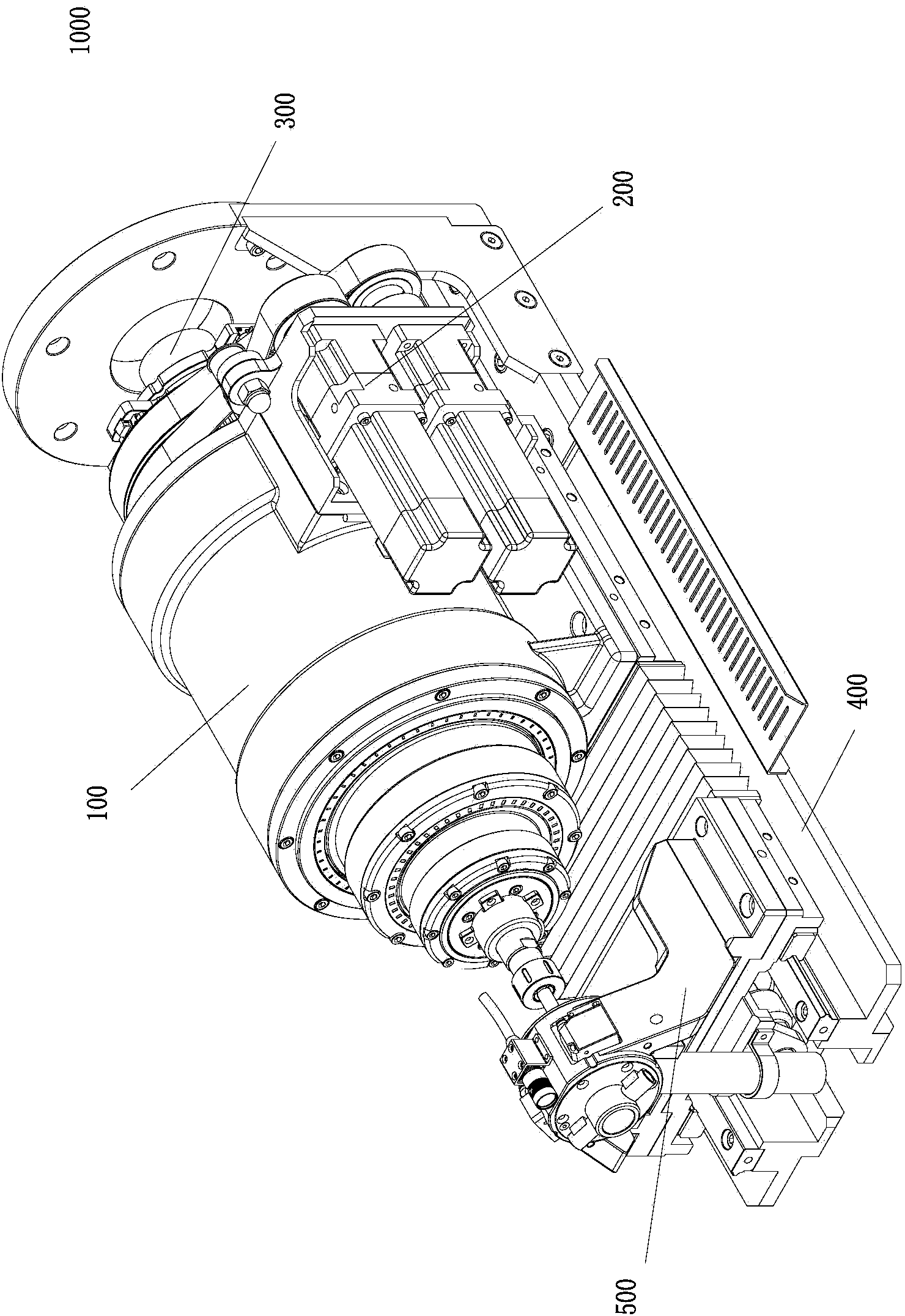

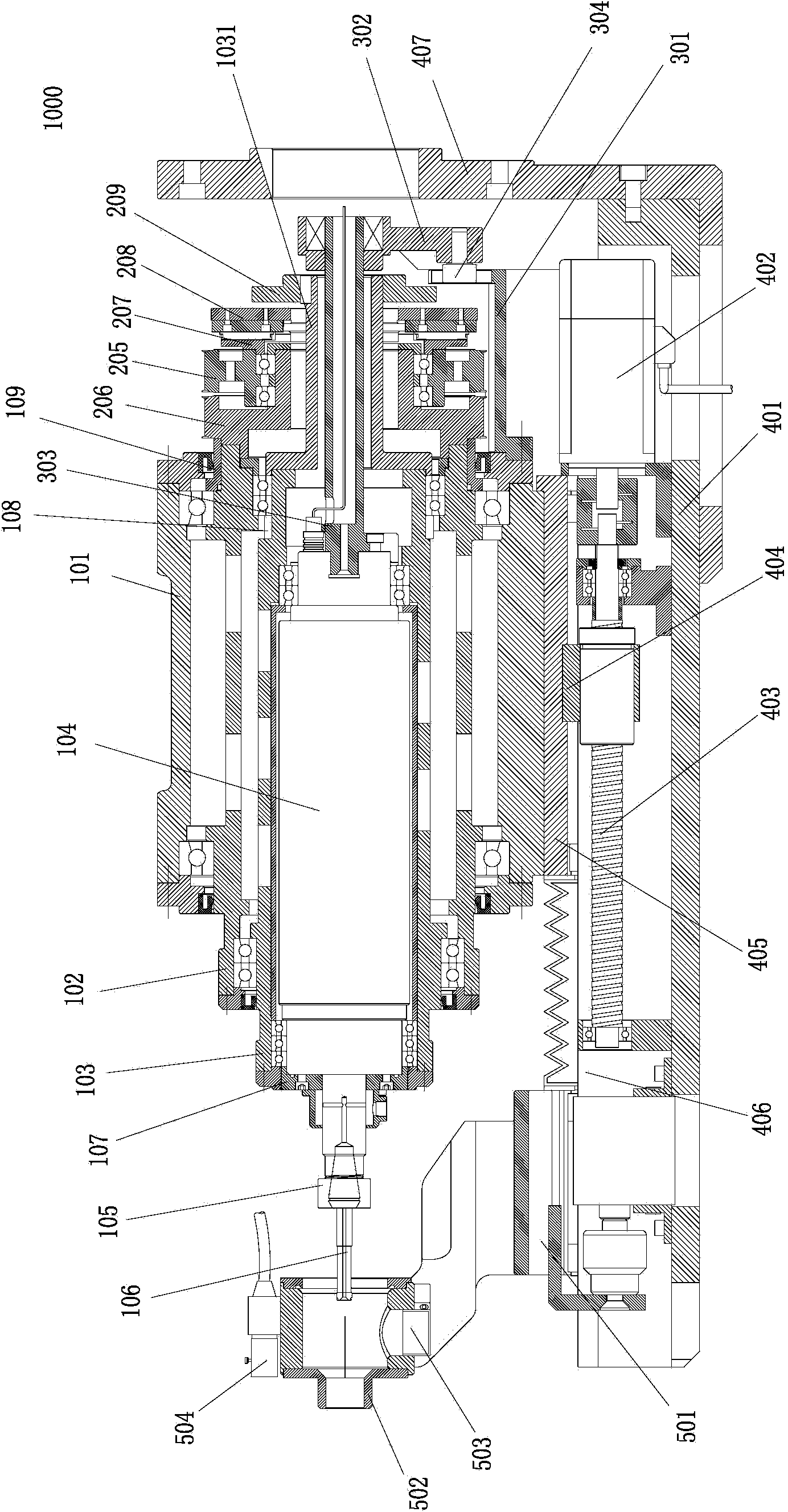

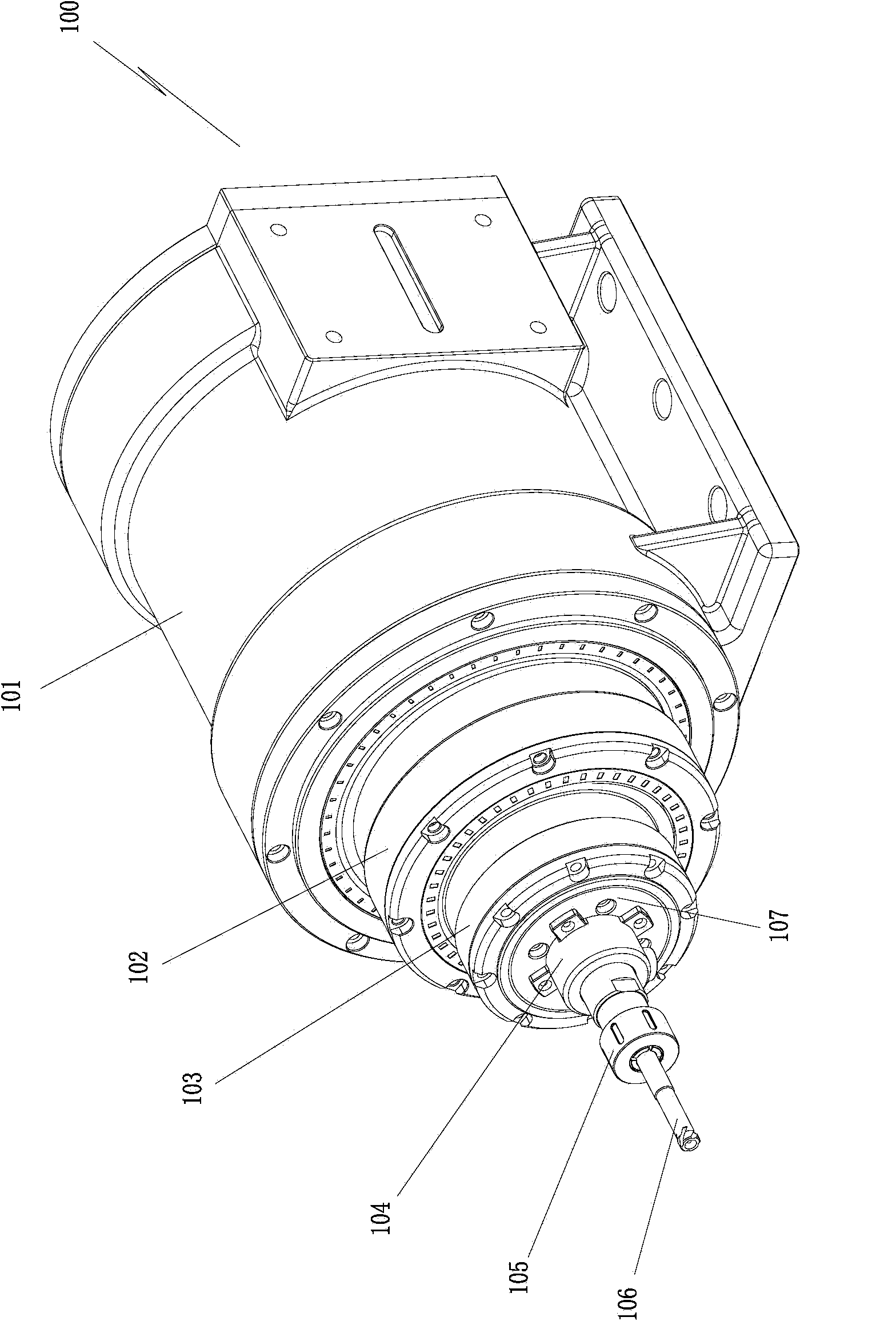

[0037] Such as figure 1 , figure 2 As shown, the present invention proposes a hole making device 1000 for online adjustment of the hole diameter; Cable anti-winding assembly 300 and presser foot assembly 500;

[0038] Such as figure 2 , Figure 6A , Figure 6B with Figure 6C As shown, the eccentric head feed platform assembly 400 includes a feed slide base 401 and a feed drive motor 402 provided on the base 401, the feed drive motor 402 is connected to a feed screw 403 through a coupling, The feed screw 403 is connected to a feed slide 405 through a nut seat 404, and the feed slide 405 is slid on a linear slide rail 406 arranged parallel to the lead screw 403; the rear portion of the feed slide base 401 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com