Refrigerated transport car, composite insulation board and manufacturing method of composite insulation board

A technology of composite thermal insulation and manufacturing method, which is applied in the direction of refrigerated cargo transportation, chemical instruments and methods, and synthetic resin layered products, etc. Problems such as small volume ratio, achieve broad market application and promotion prospects, increase available volume ratio, and reduce transportation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

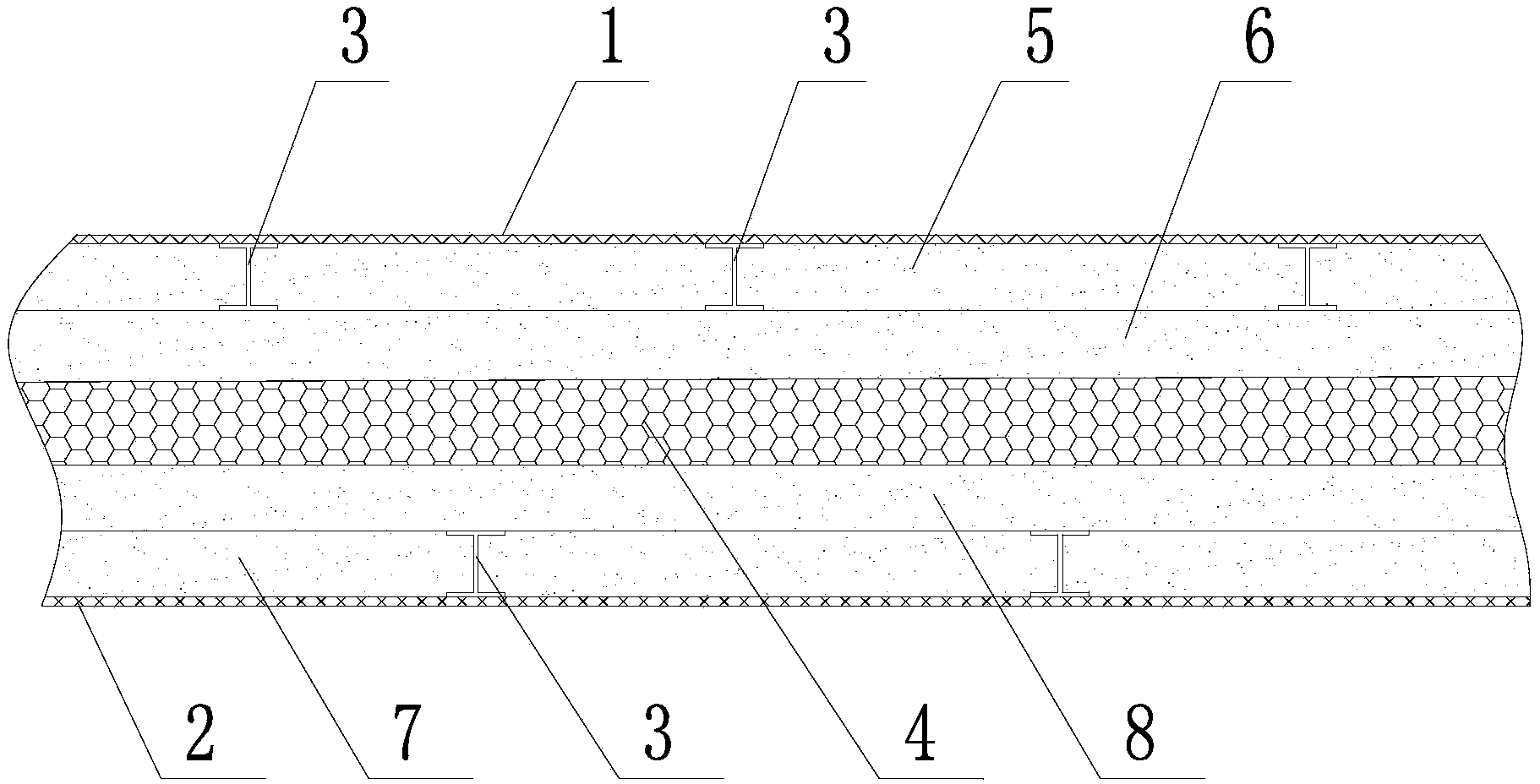

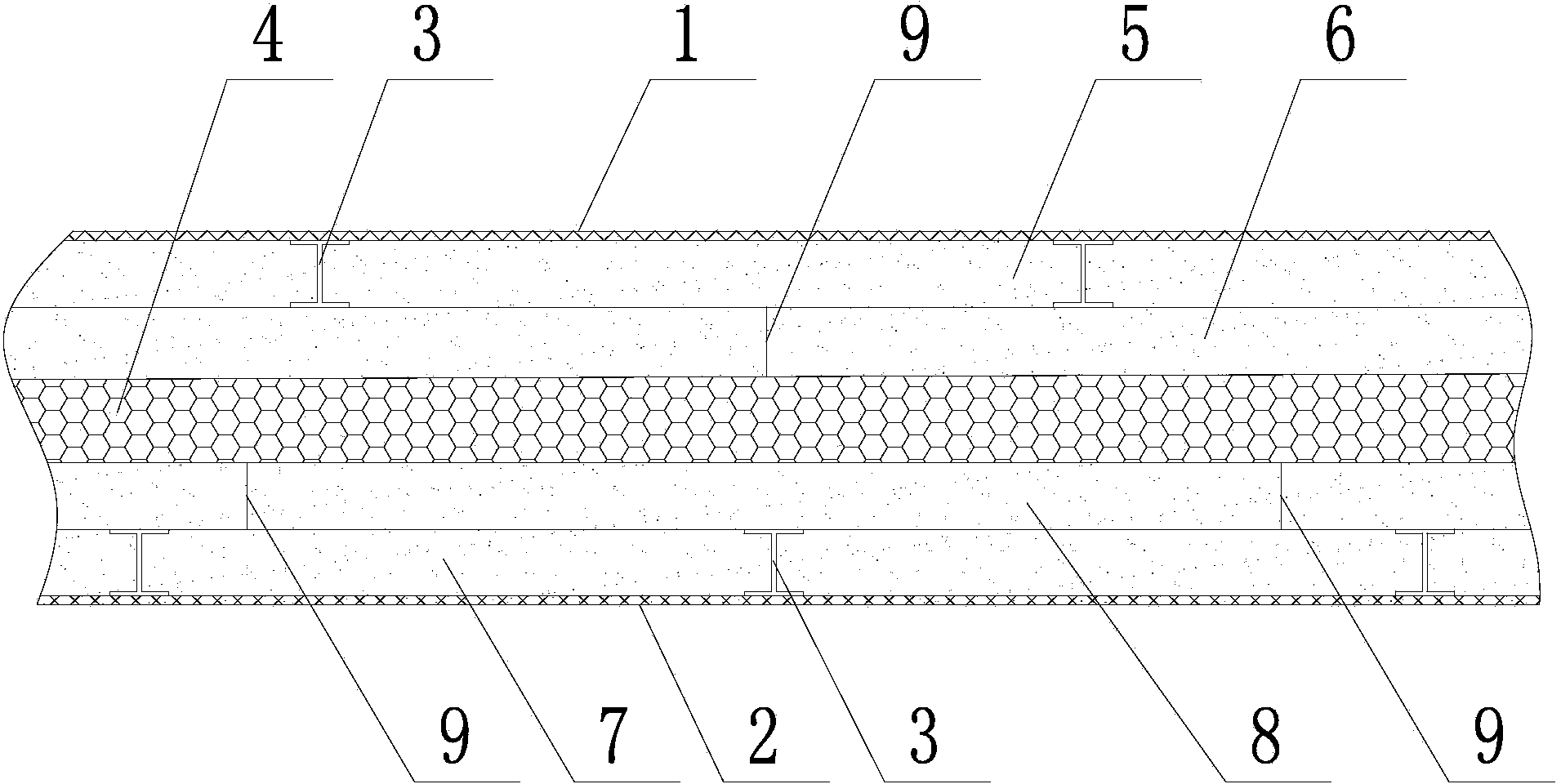

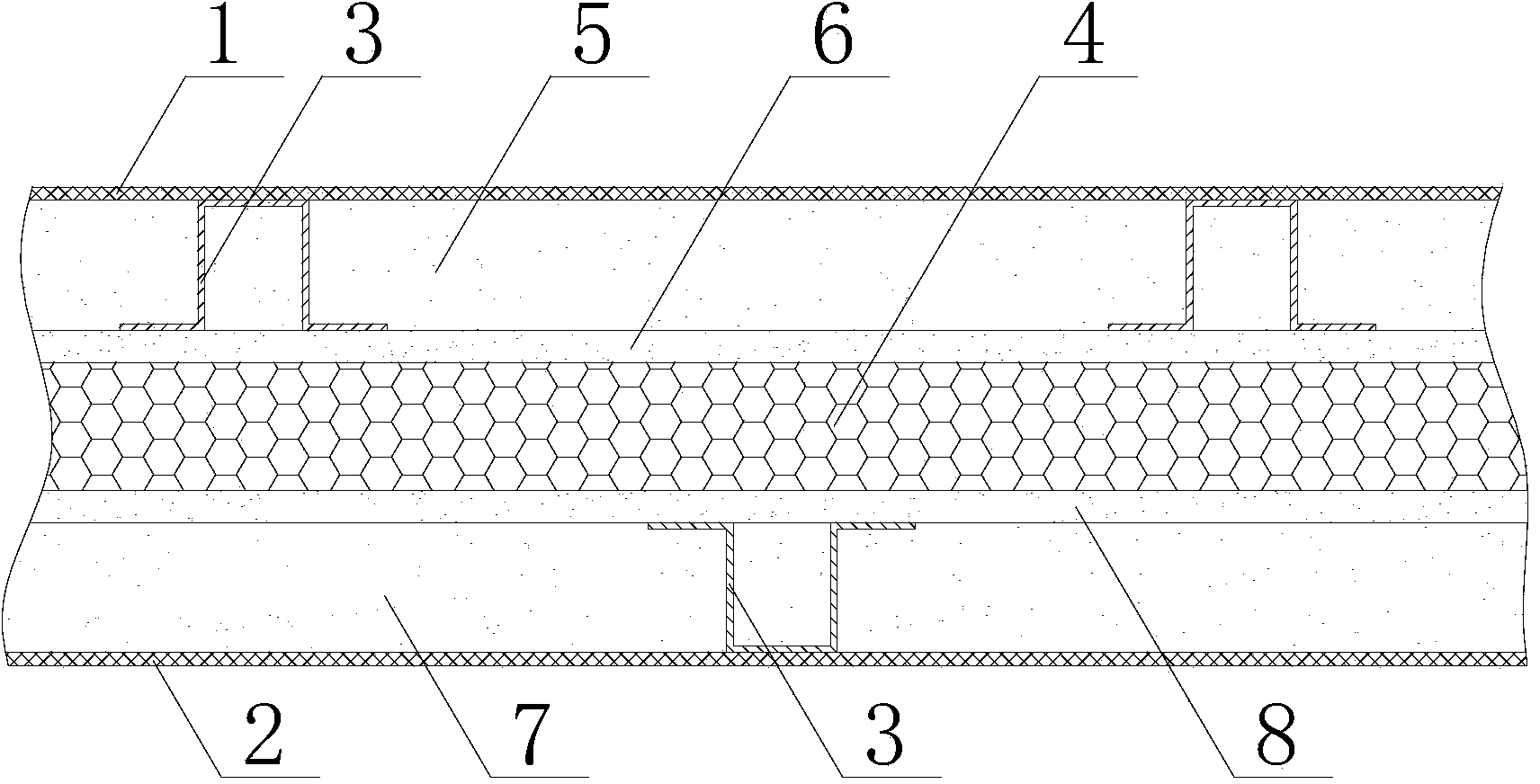

[0045] Such as Figure 1-3 As shown, a composite thermal insulation board includes an inner wall panel 1, an outer wall panel 2, and a heat insulation composite layer fixedly arranged between the inner wall panel 1 and the outer wall panel 2, and the heat insulation composite layer includes reinforcing ribs 3, vacuum The heat insulation panel 4 and the inner protection layer and the outer protection layer fixed on both sides of the vacuum insulation panel 4, the reinforcing ribs 3 are respectively embedded in the inner protection layer and the outer protection layer, and the inner protection layer and the outer protection layer They are connected with the inner wall panel 1 and the outer wall panel 2 respectively.

[0046] Such as Figure 1-3 As shown, the inner protection layer includes an inner reinforcement layer 5 and an inner stab-proof layer 6, the outer protection layer includes an outer reinforcement layer 7 and an outer stab-proof layer 8, and the reinforcing rib 3 i...

Embodiment 2

[0052] A manufacturing method for manufacturing the above-mentioned composite insulation board, comprising the following steps:

[0053] Step 1. Lay the inner wall panel flat and apply glue on it;

[0054] Step 2, paste the reinforcing ribs on the inner wall panel according to the set position;

[0055] Step 3, paste one side of the inner reinforcing layer on the inner wall panel except the part with the reinforcing rib;

[0056] Step 4, paste the inner anti-stab layer on the other side of the inner reinforcement layer and the bottom surface of the reinforcement rib;

[0057] Step 5, and then paste the inner anti-stab layer, vacuum insulation board and outer anti-stab layer in sequence;

[0058] Then, perform the following method 1 or method 2 to complete the installation:

[0059] Method one includes the following steps:

[0060] a. Paste the reinforcing rib on the outer wall panel according to the set position;

[0061] b. Paste one side of the outer reinforcing layer o...

Embodiment 3

[0069] A refrigerated transport compartment mainly consists of the above-mentioned composite insulation board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com