Charcoal-based organic fertilizer and preparation method thereof

A technology of organic fertilizer and biochar, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of non-application, etc., achieve low cost, improve soil structure, and improve soil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

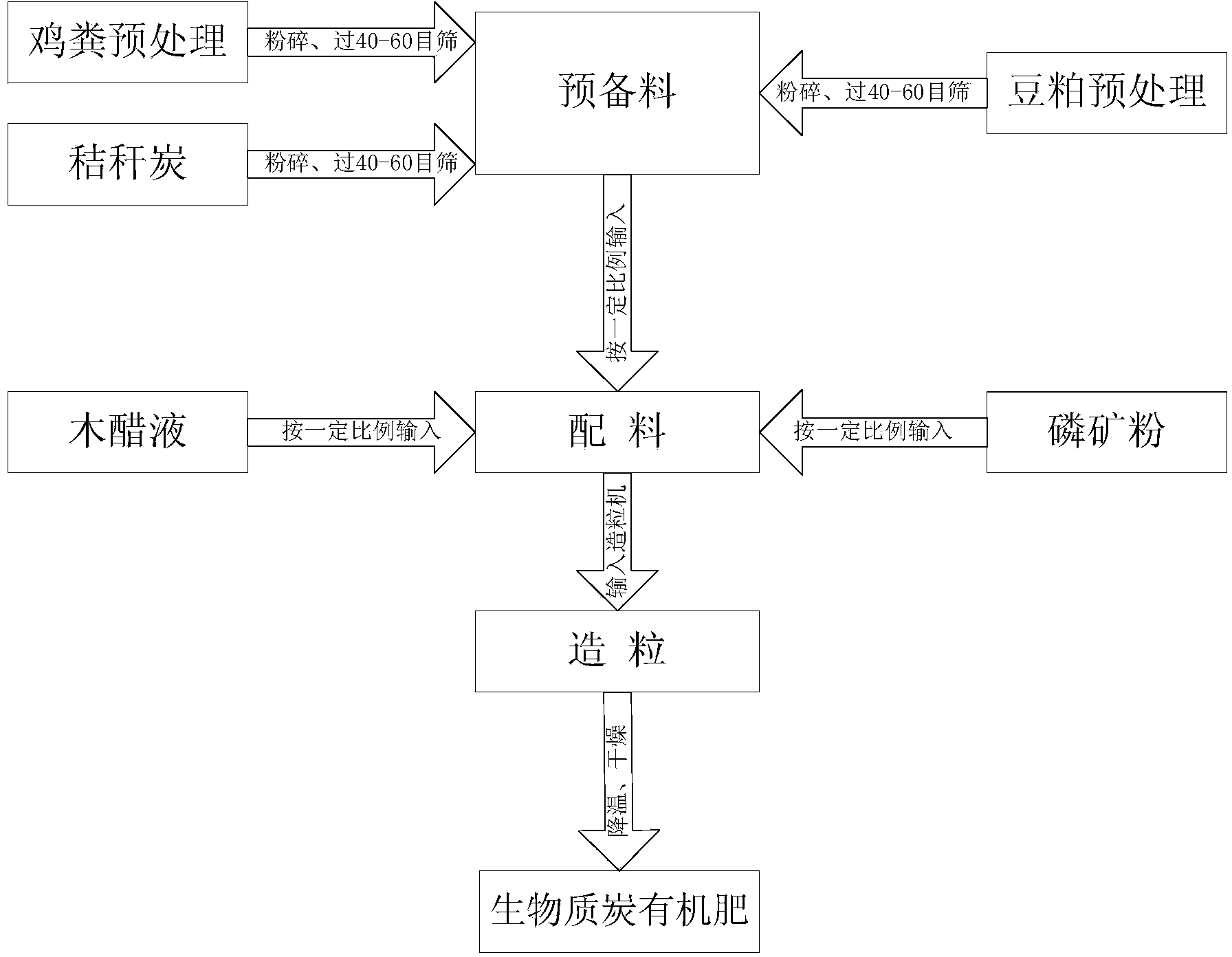

Method used

Image

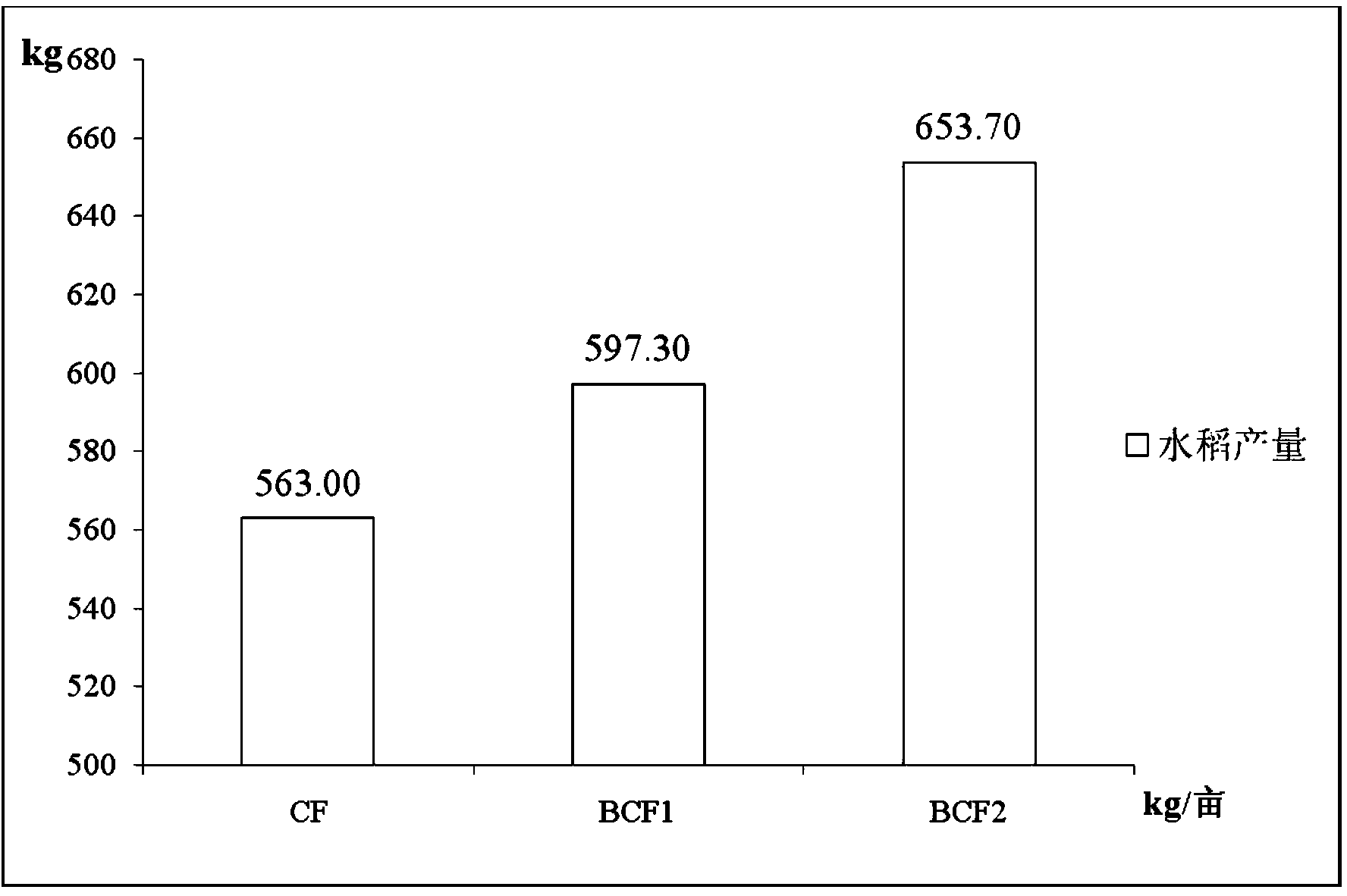

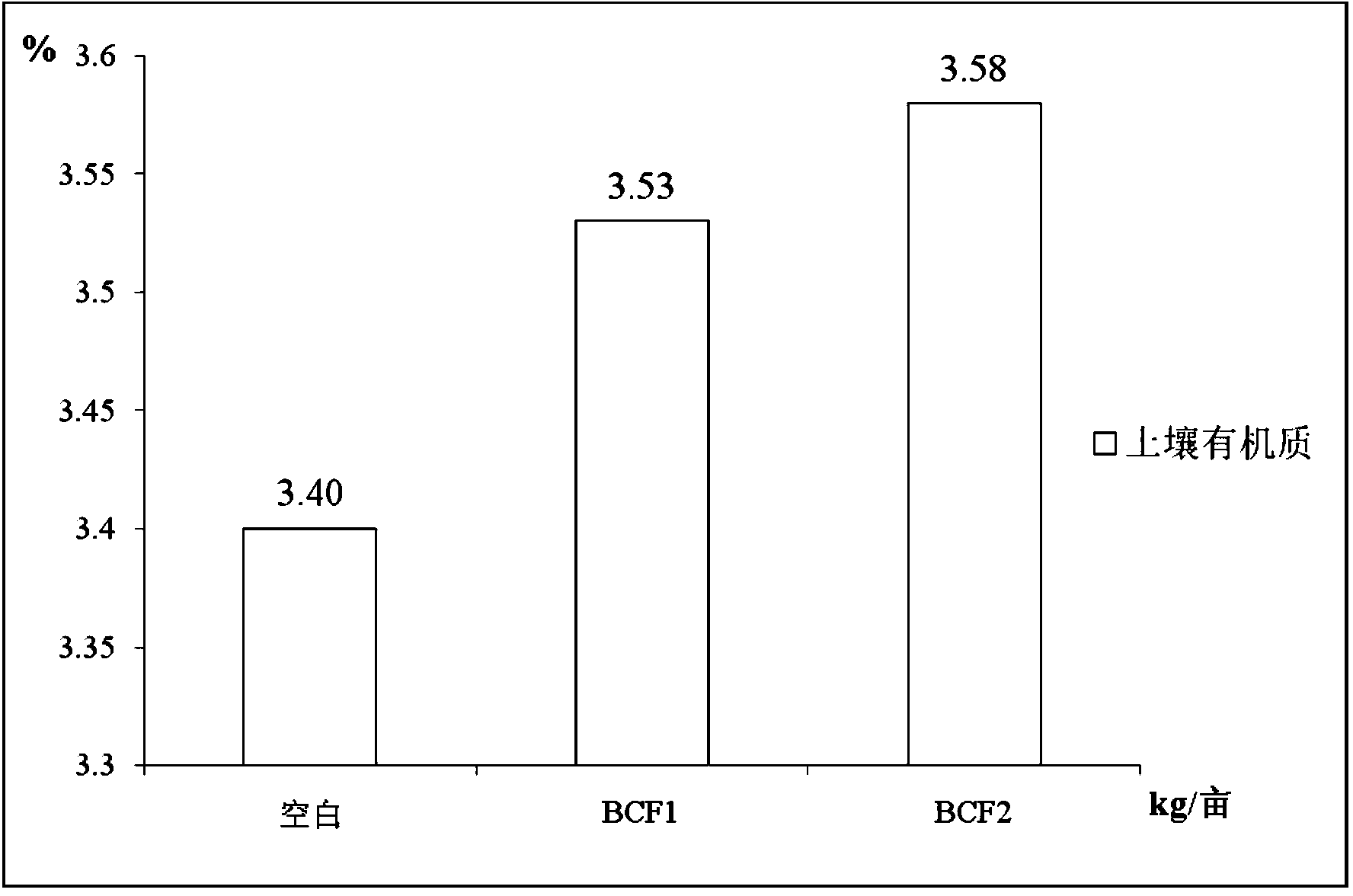

Examples

Embodiment 1

[0033] (1) Preparation of biomass straw charcoal: After drying and pulverizing 33kg of crop rice straw, carry out high-temperature pyrolysis carbonization treatment in a furnace at 400-600°C for 3 hours, and obtain 20kg of biomass straw charcoal after cooling and crushing. The flue gas formed during the heating process is separated by condensation equipment to produce by-products such as wood vinegar.

[0034] (2) Pretreatment of chicken manure: Add 55kg of raw chicken manure to 1.1kg of RW fermenting agent for organic fertilizer production in the greenhouse for aerobic fermentation, and ensure that the special RW fermenting agent for organic fertilizer production can be mixed with the The raw chicken manure is mixed evenly. During the fermentation process, ventilation is ensured. The fermentation period is 20 days. Stir and stir again in the middle. After fermentation, dry to a moisture content of 20% for later use.

[0035] (3) Soybean meal pretreatment: add 0.3kg of Ames or...

Embodiment 2

[0038](1) Preparation of biomass straw charcoal: After drying and pulverizing 58kg of crop rice straw, conduct high-temperature pyrolysis carbonization treatment in a furnace at 400-600°C for 3 hours, and obtain 35kg of biomass charcoal raw material after cooling and crushing. The flue gas formed during the heating process is separated by condensation equipment to produce by-products such as wood vinegar.

[0039] (2) Pretreatment of chicken manure: add 96.25kg of raw chicken manure to 1.93kg of RW fermentation agent for organic fertilizer production in the greenhouse for aerobic fermentation, and overthrow and stir to ensure that the special RW fermentation agent for organic fertilizer production can be compatible with the The chicken manure is mixed evenly. During the fermentation process, ventilation is ensured. The fermentation period is 20 days. Stir and stir again in the middle. After the fermentation process, it is dried to a moisture content of 20% for later use.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com