Polyurethane wood substitution composition

A technology of polyurethane and composition is applied in the field of manual preparation of the model products, which can solve the problems such as short operating time of pasty wood substitutes, and achieve the effects of good hardness and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

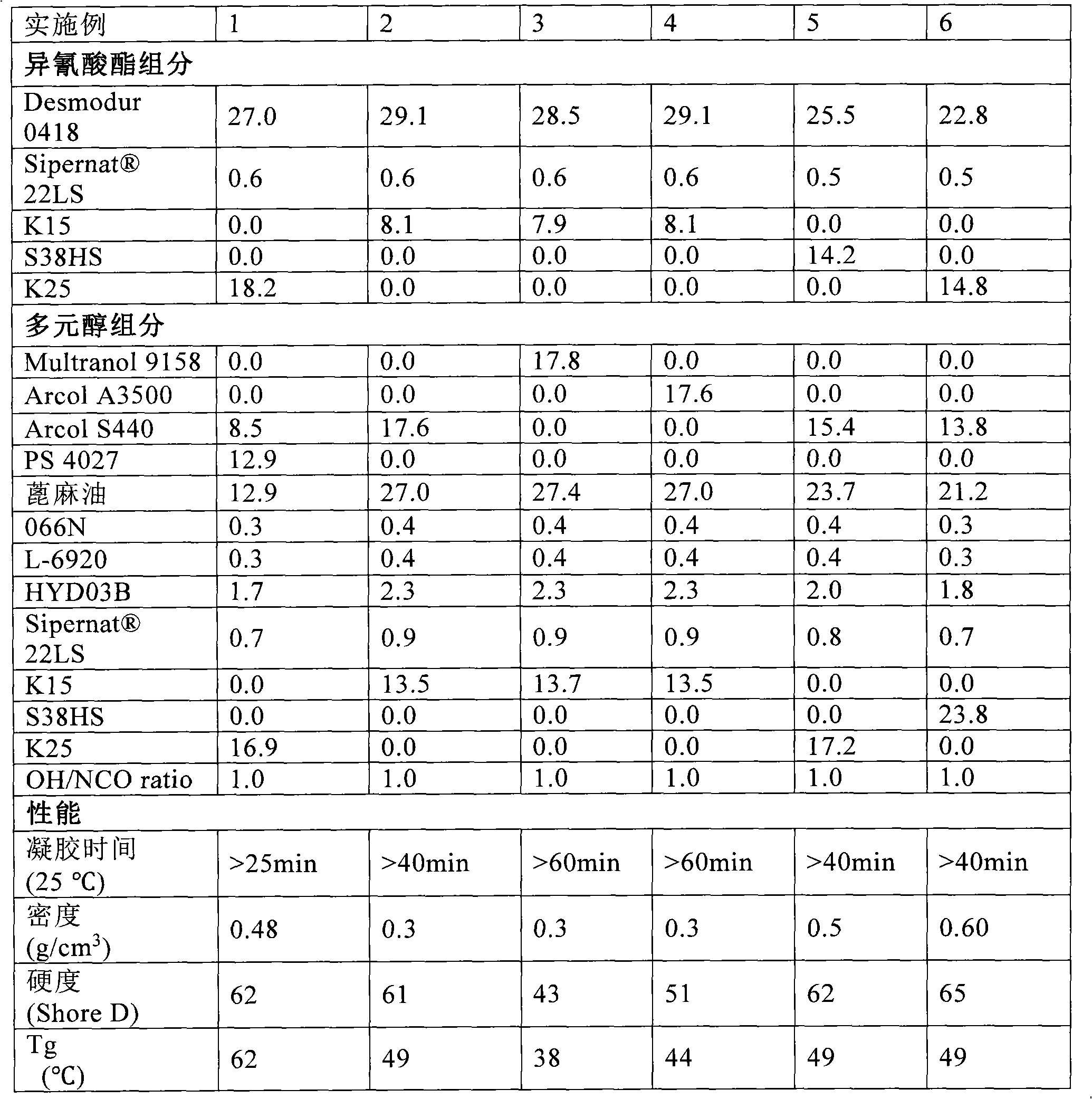

[0112] Embodiment 1: adopt the following steps to implement. Prepare 1000g of materials according to the weight percentages shown in Table 1, and mix them by hand. All operations (weighing and mixing) were performed at room temperature in a fume hood (temperature 20-25°C, relative humidity 45% to 55%).

[0113] 300g of the mixed material was horizontally applied to a vertical surface of a foam substrate with a thickness of 20mm, 30mm, 40mm and 50mm to evaluate its anti-sag performance.

[0114] Apply 500g of the mixed material to a foam substrate with a thickness of 30mm. After curing at room temperature for 12 hours, use a CNC machine tool to process it into a designed shape, and use an electronic magnifying glass to observe its surface quality.

[0115] The remaining 200g material is used to test Shore D hardness and density, the test standards are ISO868:2003 and ISO2781:1996 respectively

[0116] The operation method of embodiment 2-6 is the same as embodiment 1, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com