Ultra-low temperature toughened polypropylene composition

A polypropylene composition and ultra-low temperature technology, which is applied in the field of polypropylene composition, can solve the problems of unsatisfactory automobile safety performance, evaluation of multi-axial low-temperature impact strength, insufficient comprehensive performance of low-temperature impact toughness and rigidity, etc., and achieve good rigidity , maintain rigidity, and improve low-temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

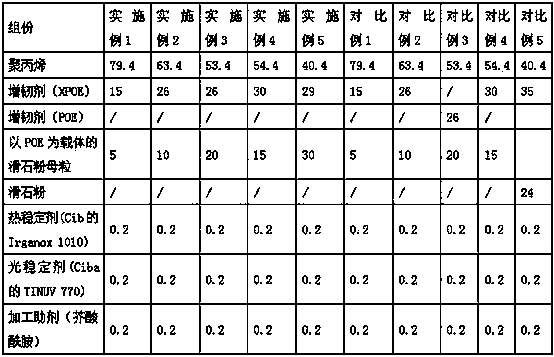

Embodiment 1-5、 comparative example 1-5

[0035] A kind of polypropylene composition, its preparation method comprises the following steps:

[0036] (1) Mix 20% POE and 80% talcum powder at 170°C, granulate and cool to obtain talcum powder masterbatch with POE as the carrier; the percentages mentioned are the percentages of each raw material in the total mass of raw materials;

[0037] (2) The raw material formula of the polypropylene composition is shown in Table 1. After mixing the raw materials, put them into a twin-screw extruder, melt and mix them at 230°C, and then granulate and cool to obtain a polypropylene composition.

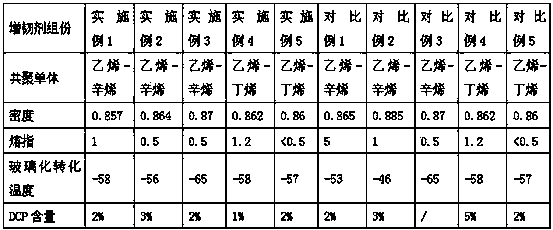

[0038] The tougheners used in the examples and comparative examples are different, and their specific performance parameters are shown in Table 2.

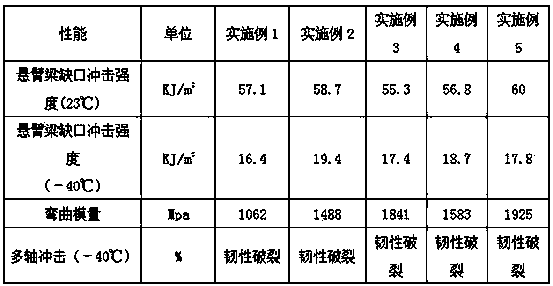

[0039] The polypropylene composition that embodiment and comparative example obtain adopts the following methods to test its relative performance:

[0040] (1) Flexural modulus: tested according to ISO178, the speed is 2mm / min;

[0041] (2) Izo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com