Corrosion-free anti-wear semi-synthetic cutting fluid and preparation method thereof

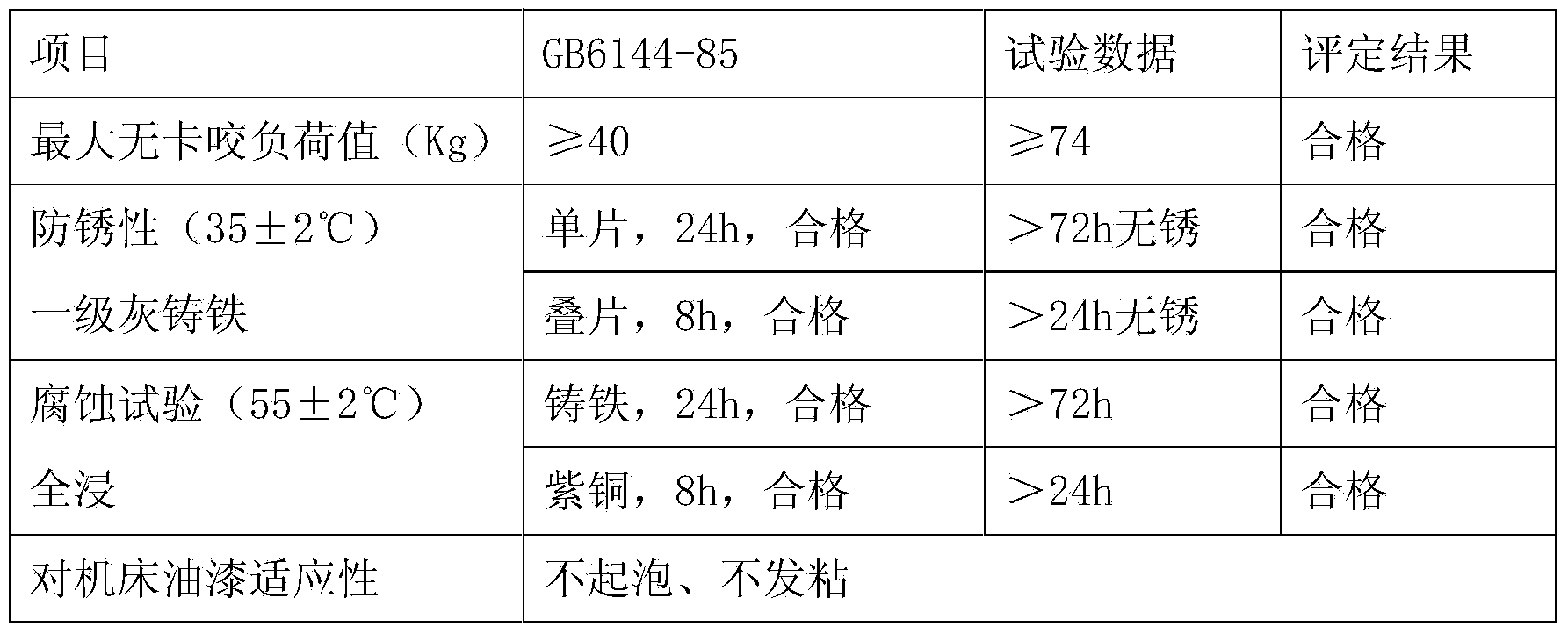

A semi-synthetic, cutting fluid technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of polluted environment, poor cooling performance, poor lubricity and anti-rust effect, etc., and achieve good anti-settling performance, good lubricity, Good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A non-corrosion and anti-wear semi-synthetic cutting fluid, made of the following raw materials in parts by weight (kg): mineral oil 13, ricinoleic acid 3.5, diethanolamine 1.5, isopropanol 11, fatty acid polyoxyethylene ester 3.5, diamond nano Particle 1.5, pentaerythritol 1.5, lauryl polyoxyethylene ether 2.5, lanthanum acetate 0.08, auxiliary agent 7, water 200; the auxiliary agent is made of the following raw materials in parts by weight (kg): polyoxyethylene sorbitan Oleate 2, nano aluminum nitride 0.1, citric acid 1, sodium tripolyphosphate 3, ammonium persulfate 2, silane coupling agent KH-5602, sodium molybdate 2, peach gum 3, water 20-24; preparation method Dissolve ammonium persulfate in water, then add other remaining materials, stir for 10-15 minutes, heat to 70-80°C, and stir for 1-2 hours to obtain the product.

[0010] The preparation method of the non-corrosion and anti-wear semi-synthetic cutting fluid comprises the following steps: mixing water, isopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com