Method for extracting crude salamander oil from giant salamander tail fat by using papain

A technology of papain and fat extraction, which is applied in the direction of fat production, fat oil/fat production, etc., can solve the problem of low extraction rate of giant salamander oil, improve product added value and resource utilization, mild reaction conditions, and wide range of process parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) First, separate the fat of the giant salamander tail from the skin to obtain the fat of the giant salamander tail, weigh 100g of the fat of the giant salamander tail, and then stir it into a minced shape;

[0015] (2) Add 100g of water to the minced giant salamander tail fat and mix, adjust the pH to 6.7 with HCl and NaoH, 0.3g of papain, shake well and heat up to 55°C, stir and oscillate for 1 hour.

[0016] (3) The enzymatic hydrolysis solution obtained in (2) was centrifuged at 4000r / min for 10 minutes, and then divided into three layers after centrifugation, the upper layer was clear light yellow salamander oil, the middle layer was hydrolyzed components, and the lower layer was hydrolyzed rich in polypeptides and amino acids. Liquid protein hydrolyzate, absorb the upper layer to obtain crude salamander oil 98.53g.

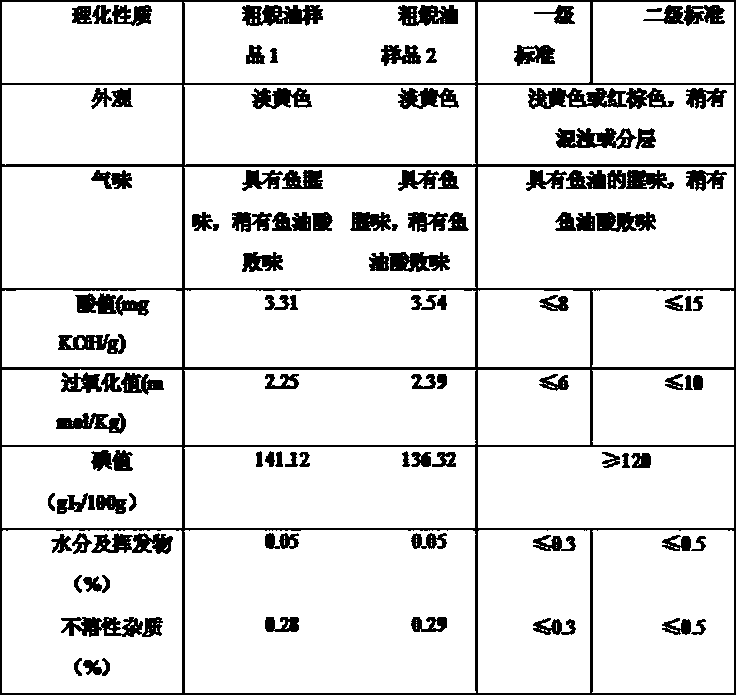

[0017] The extraction rate of crude salamander oil was 98.53%. The analysis results of its physical and chemical properties are shown in crude sala...

Embodiment 2

[0019] (1) First, separate the fat from the tail of the giant salamander to obtain the fat from the tail of the giant salamander, weigh 100g of the fat from the tail of the giant salamander, and stir it into a minced shape

[0020] (2) Add 100g of water to the minced giant salamander tail fat and mix it with HCl and NaoH to adjust the pH to 6.5. The weight of the subcutaneous fat of the giant salamander tail is used as the standard, add 0.1g of papain, shake well and heat up to 55°C, stir Shock reaction 1.5h.

[0021] (3) The enzymatic hydrolysis solution obtained in (2) was centrifuged at 5000r / min for 10min, and then divided into three layers after centrifugation, the upper layer was clarified light yellow salamander oil, the middle layer was hydrolyzed components, and the lower layer was hydrolyzed rich in polypeptides and amino acids Liquid protein hydrolyzate, absorb the upper layer to obtain crude salamander oil 98.4g.

[0022] The extraction rate of crude salamander oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com