Building thermal-insulation wallboard

A technology for building thermal insulation and wall panels, which is applied to buildings, building components, building structures, etc., can solve problems such as improper material application measures, and achieve the effects of good thermal insulation effect, shortened project construction period, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

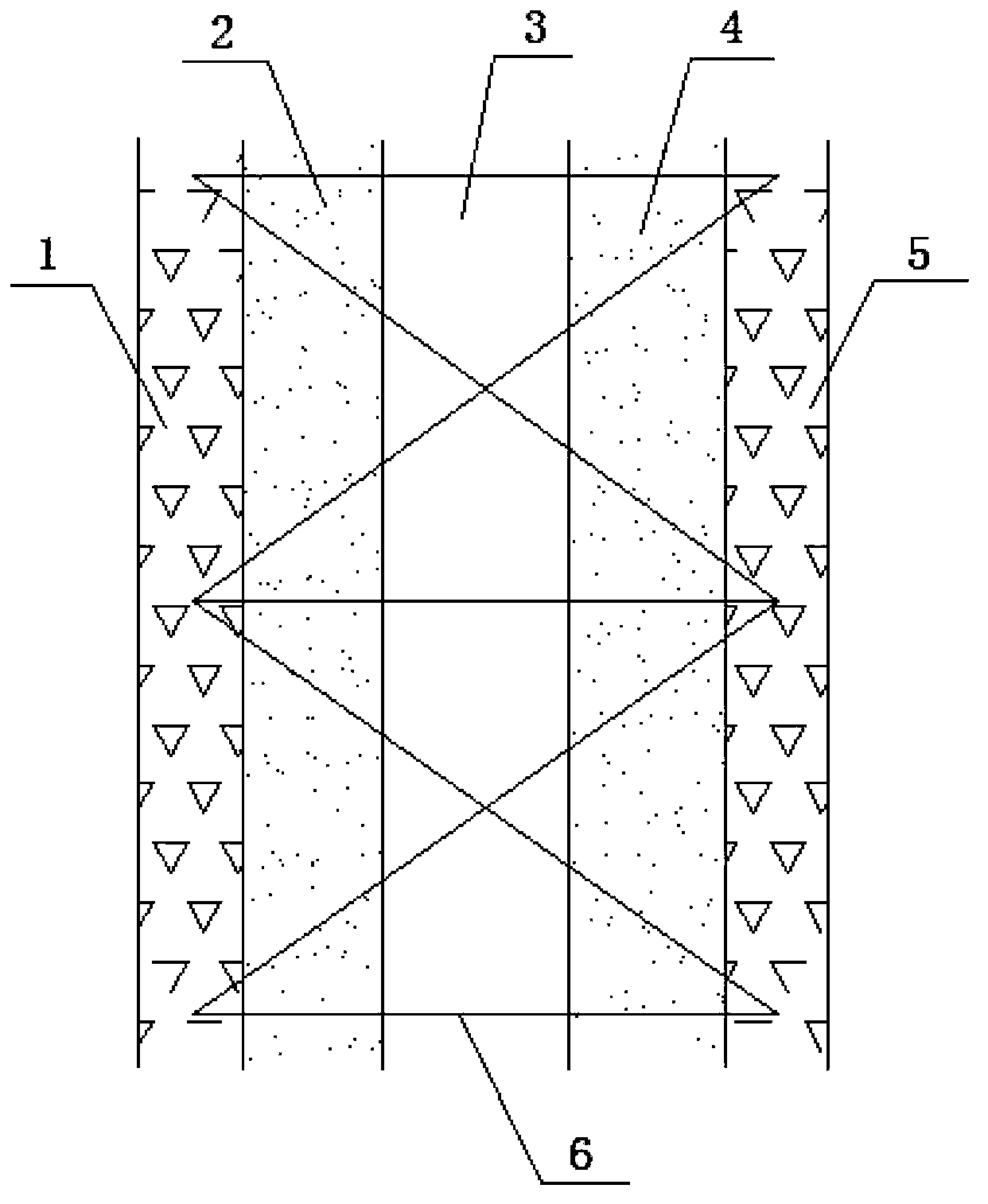

[0012] Such as figure 1 As shown, the present invention includes an outdoor surface concrete layer 1, an indoor surface concrete layer 5, and a steel mesh skeleton 6. One side of the steel mesh skeleton 6 is fixedly connected to the outdoor surface concrete layer 1, and the other side is fixedly connected to the indoor surface concrete layer 5; The steel mesh frame 6 is made of galvanized steel wire, and the outdoor surface concrete layer 1 and the indoor surface concrete layer 5 are made of high-grade cement, water, artificial hard rock sand, micro-silica fume, first-grade fly ash, alkali and crack resistance Fiber and high-efficiency water reducing agent are mixed and stirred. An outer thermal insulation layer 2 is fixedly connected to the inner side of the outdoor concrete layer 1, and an inner thermal insulation layer 4 is fixedly connected to the outer side of the indoor concrete layer 5. There is an air spacer layer 3 between the layer 2 and the inner insulation layer 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com