Colorful flexible roof tile and preparation method thereof

A roofing tile and color flexible technology, applied in the direction of roofing, roofing, roof covering and other directions using flexible materials, to achieve the effect of reducing the load-bearing of buildings, reducing roofing loads, and simplifying the layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

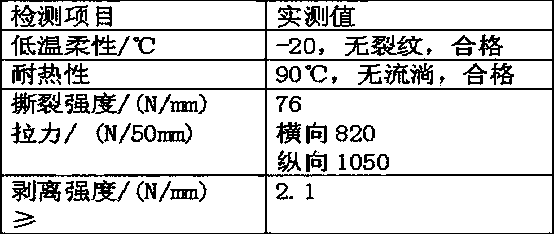

Embodiment 1

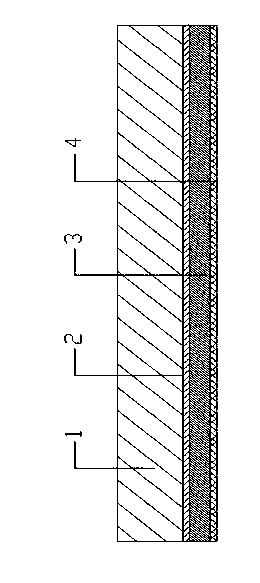

[0027] Example 1: Red fish scale type low surface energy durable colorful flexible roof tile, its structure see figure 1 , the tile has a four-layer structure, and the order of arrangement of the four-layer structure from top to bottom is modified TPO layer 1, functional film layer 2, high temperature resistant self-adhesive asphalt layer 3, isolation film layer 4, four layered structure Composite as a whole, the overall specification is length × width = 1000mm × 333mm, thickness 2-5mm, exposed surface length 145mm, tile type is Goethe type or fish scale type or rhombus type. Present embodiment is red fish scale type.

[0028] The modified TPO layer in this embodiment is a homogeneous layer modified by ultra-fine polytetrafluoroethylene powder with a thickness of 3mm. Or strengthen the TPO layer in the fabric, and the functional film layer 2 is cpp aluminized film with a thickness of 0.1mm. The thickness of the self-adhesive rubber asphalt layer 3 is 1mm. The isolation f...

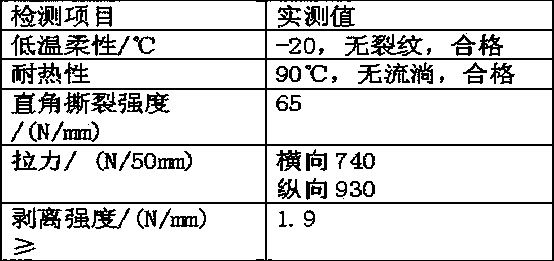

Embodiment 2

[0046] 1. Blue Goethe-type low surface energy durable colorful flexible roof tiles

[0047] (1) The tile has a four-layer structure, and the arrangement sequence of the four-layer structure from top to bottom is modified TPO layer 1, functional film layer 2, high temperature resistant self-adhesive asphalt layer 3, isolation film layer 4, four-layer layered structure Composite as a whole, the whole specification made is length×width=1000mm×333mm, thickness 4mm, exposed surface length is 145mm, and the tile type of the present embodiment is the blue Goethe type.

[0048] (2) The modified TPO layer in this embodiment is a reinforced TPO layer in the fabric with a thickness of 2 mm, and the functional film layer 2 is a cpp aluminized film with a thickness of 0.1 mm. The thickness of the self-adhesive rubber asphalt layer 3 is 2.5mm. The isolation film layer is a silicon-coated release paper or a silicon-coated release film.

[0049] 2. Preparation method of 4mm thick blue Go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com