High-efficiency high pressure head three-dimensional flow impeller

A ternary flow and impeller technology, applied in pump elements, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve the problems of low pressure head, large error, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the accompanying drawings and embodiments.

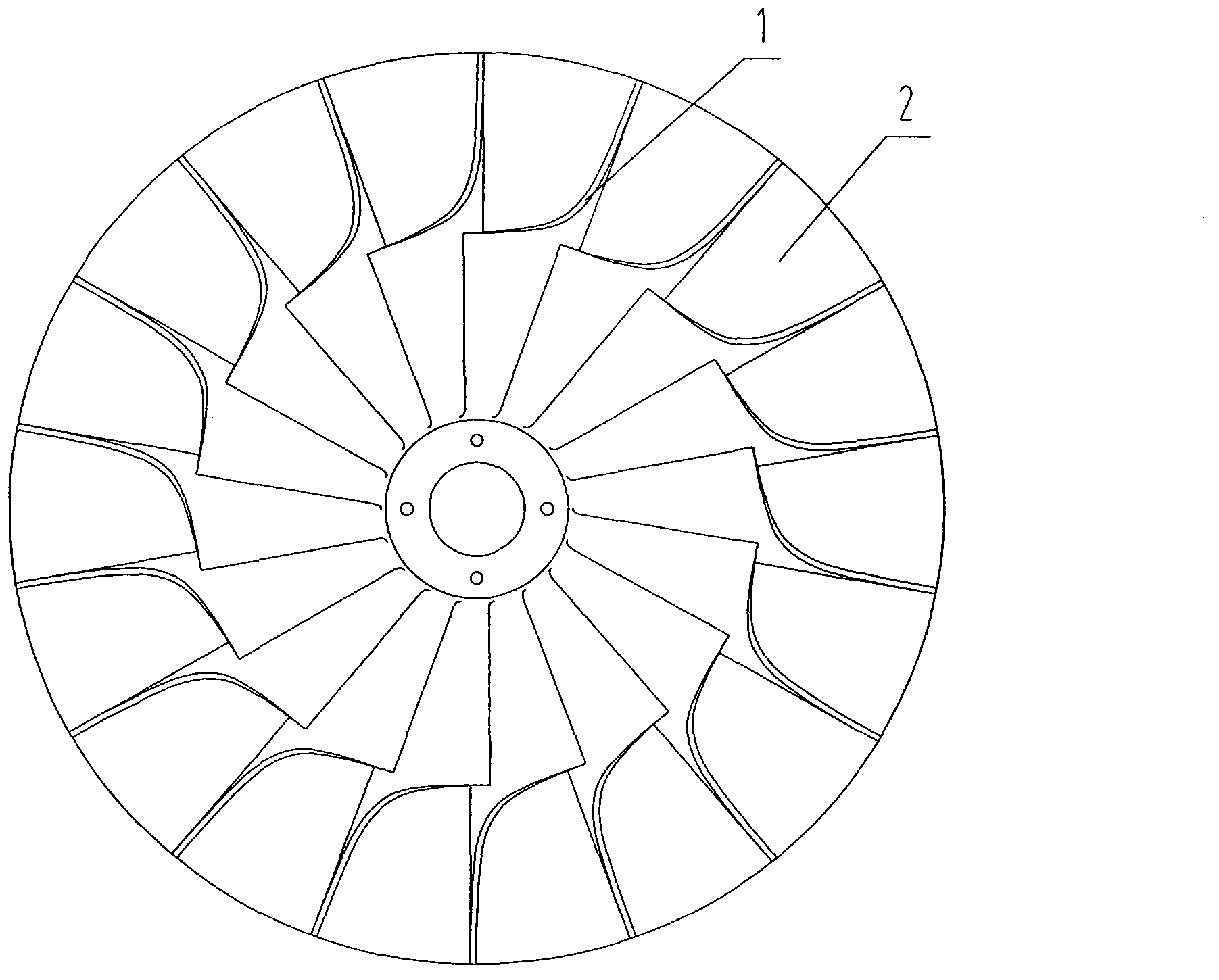

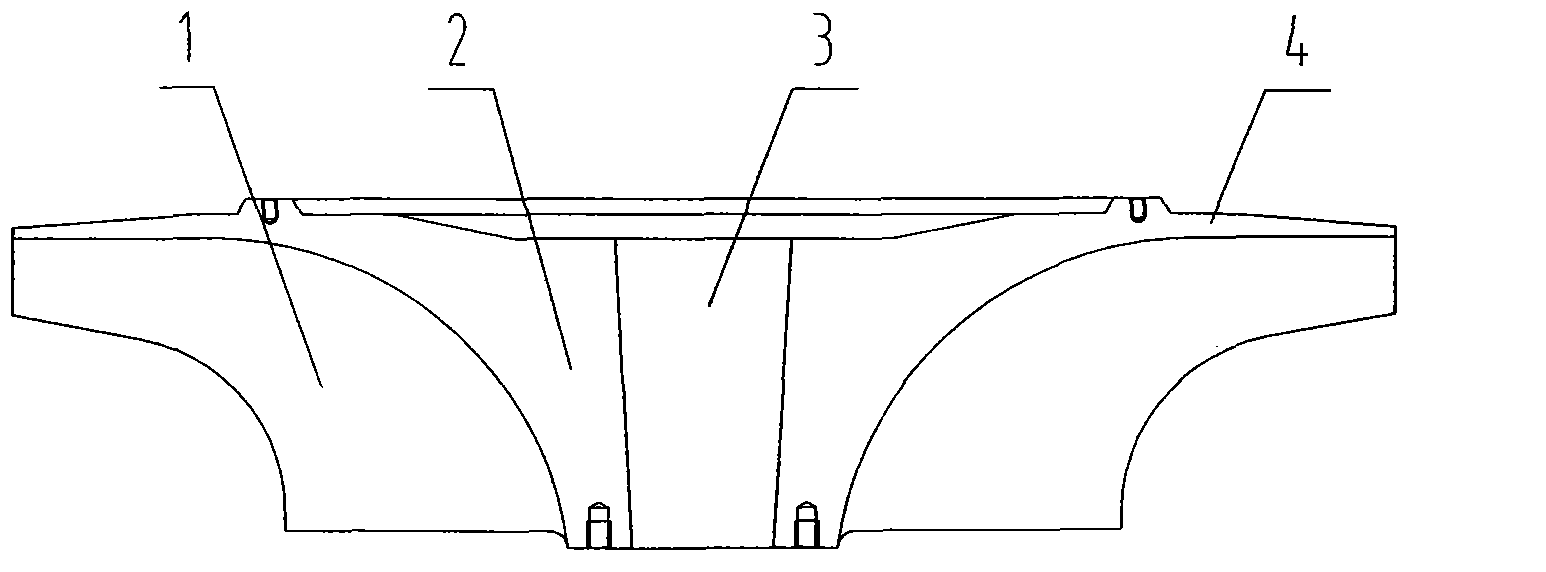

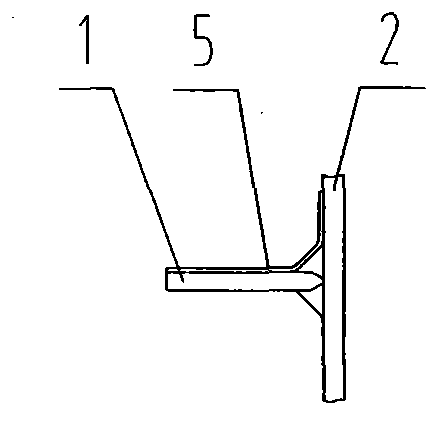

[0011] exist figure 1 , figure 2 and image 3 Among them, the impeller is welded by the blade 1 and the disc 2, the disc 2 has a tapered hole 3, the periphery of the disc 2 is a disc 4 of unequal thickness, and the pressure surface of the blade 1 and the surface of the welding seam are sprayed with nickel-chromium alloy The powder layer 5 has a thickness of 0.2-0.3 mm.

[0012] The material of blade 1 is precipitation hardening stainless steel FV520B, and the material of disc 2 is 15MnNiCrMoV, both of which are anti-corrosion. The welding seam is welded by FV520B special electrode; The energy head of the back-curved blade is about 20% higher. Under the same energy head, the diameter of the impeller is reduced, so the radius of the volute is also reduced, which greatly reduces the cost; the design of the air guide section at the inlet of blade 1 is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com