Glass reinforced plastic-lined pipe and production method thereof

A production method and technology of plastic-lined pipes, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of easy aging and inability to guarantee related performance, and achieve the effects of not easy aging, saving materials, and slowing down aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

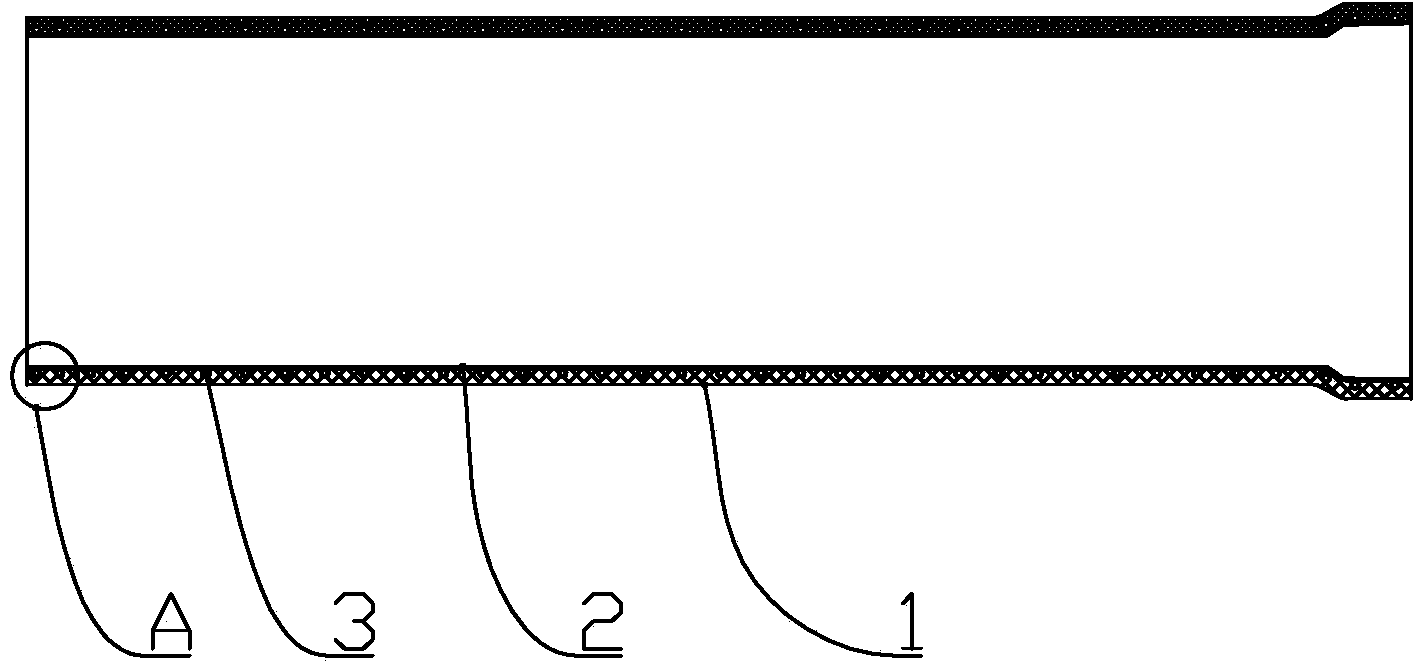

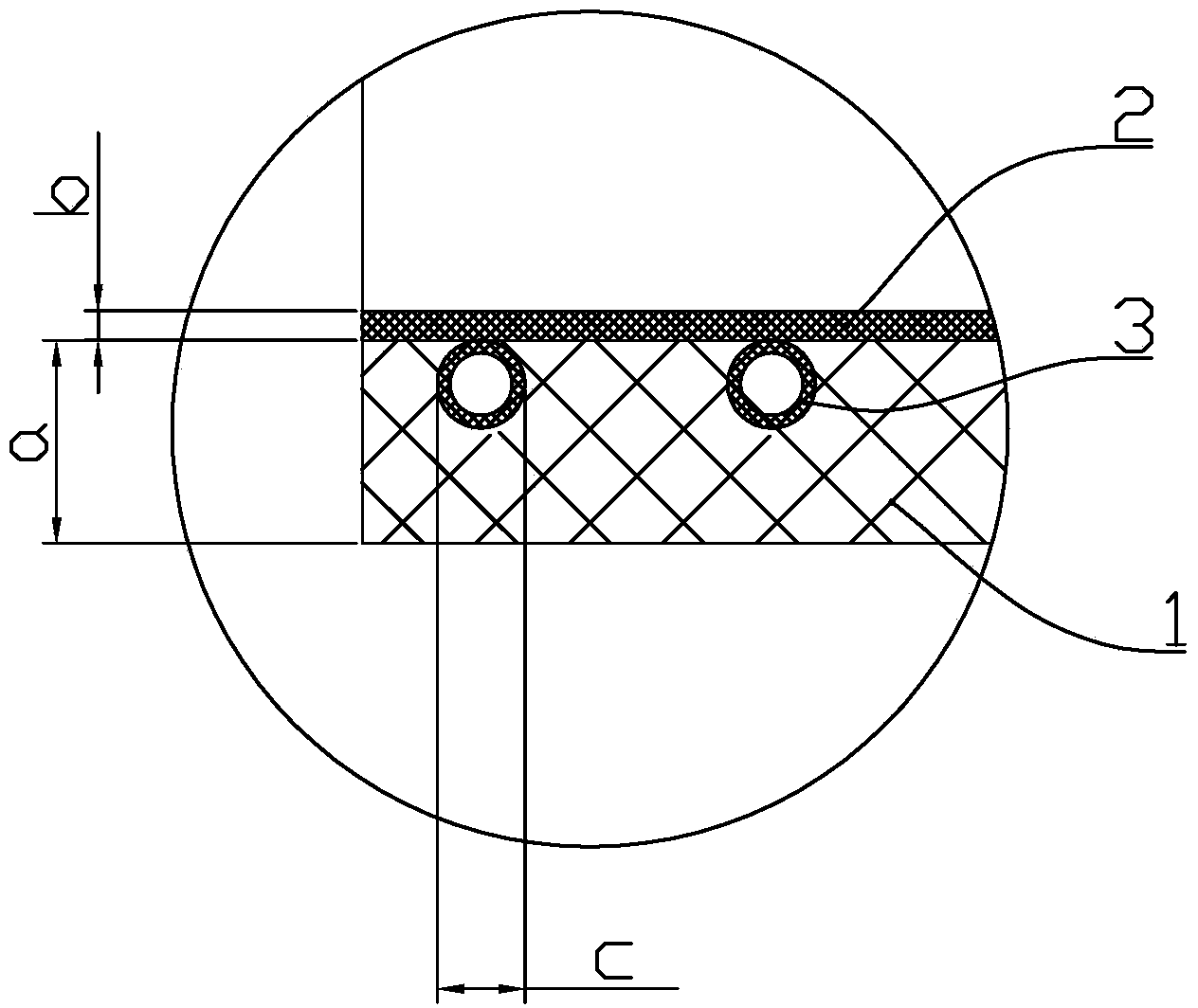

[0014] according to Figure 1 to Figure 2 As shown, the FRP-lined plastic pipe described in this embodiment includes a FRP layer 1, the inner wall of the FRP layer is provided with a layer of PE inner pipe 2, and the outer periphery of the PE inner pipe is welded with a hollow PE spirally wound on the outer wall of the PE inner pipe. The spiral rib pipe 3, the PE spiral rib pipe is embedded in the inner wall of the glass fiber reinforced plastic layer 1. The PE inner pipe has better moisture-proof and anti-corrosion performance, and is not easy to age. The glass fiber reinforced plastic layer has higher hardness and mechanical strength. service life. PE is a food-grade hygienic material, making the pipe suitable for the field of water supply pipes. The thermal expansion coefficients of the FRP layer and the PE inner pipe are different,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com