Oscillation impact testing device

A shock test and launcher technology, applied in shock test, measuring device, ammunition test, etc., can solve the problems of insufficient test accuracy, limited test result authenticity, unstable control of test conditions, etc., to achieve convenient installation and disassembly, Realize the effect of fast impact and strong work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

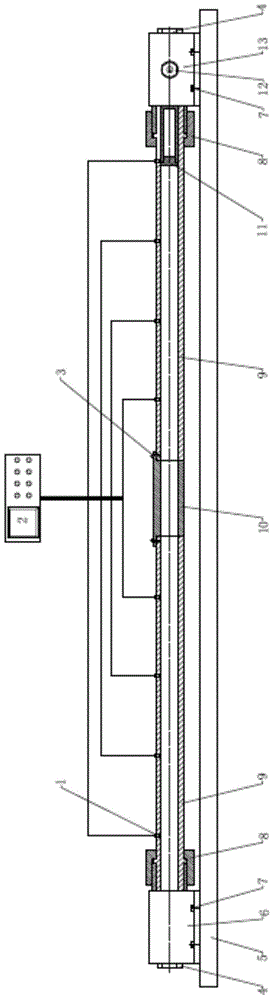

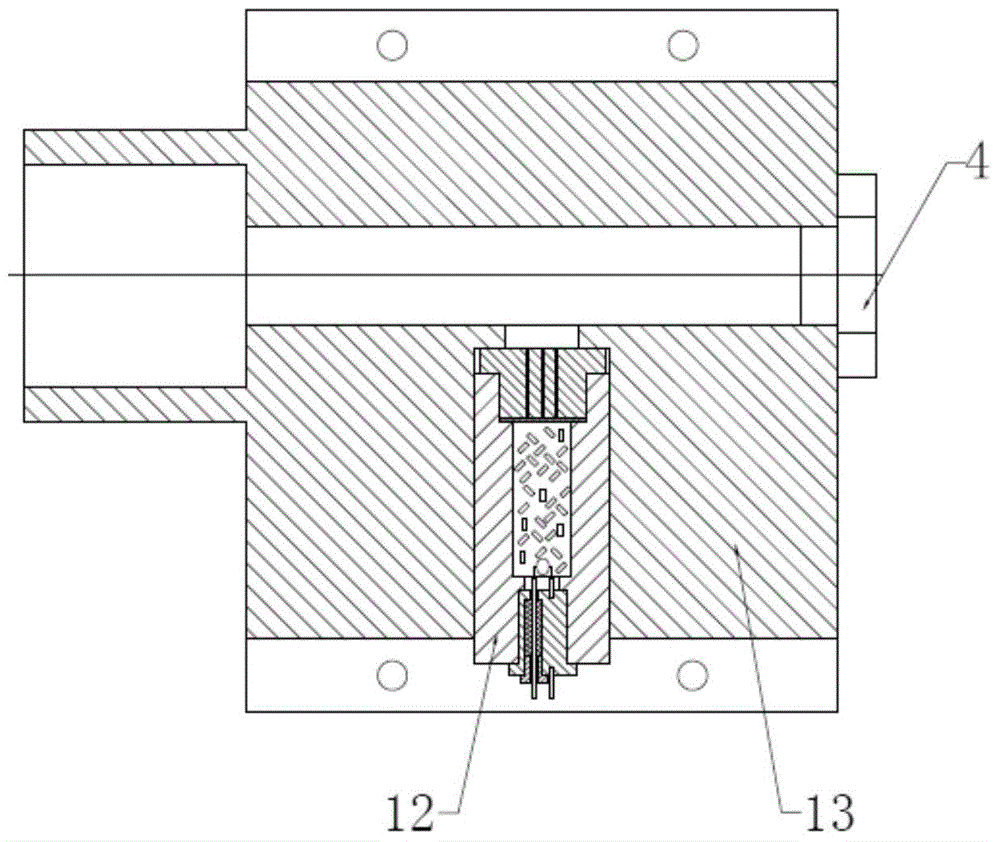

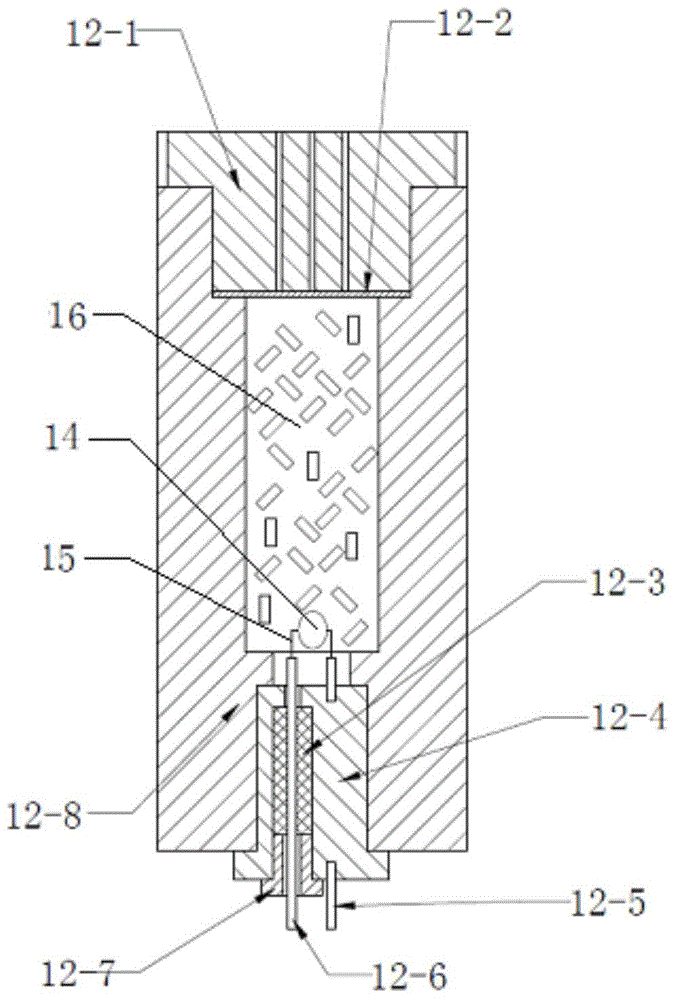

[0034] like figure 1 , Figure 4 and Figure 5 As shown, the shock and impact test device of the present embodiment includes an oscilloscope 2, a sensor 1, a stand 5, a body tube seat 6, two body tube connecting hoops 8, two body tubes 9, a guide tube 10, a carrier 11, Launcher 12 and launcher seat 13. in:

[0035] The stand 5 is a cuboid, made of square steel, with 8 holes on both sides for installing the barrel seat 6 and the launcher seat 13.

[0036] The body tube seat 6 is a cylinder with two ends open, and its inner hole is a circular stepped hole, and the end of the smaller section of the body tube seat 6 is provided with an external thread cylindrical boss, and the screw on the boss Connect with a plug 4 to close this end of the barrel seat 6; the seat plug 4 is a circular cover with an internal thread matched with the external thread of the boss.

[0037] The launcher seat 13 is a cylinder with two ends open, and its inner hole is a circular stepped hole, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com