Method for preparing integrated silicon piezoresistive type sensor chip preparing and sensor chip

A sensor chip, silicon piezoresistive technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc., can solve problems such as small size and reduce chip size volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

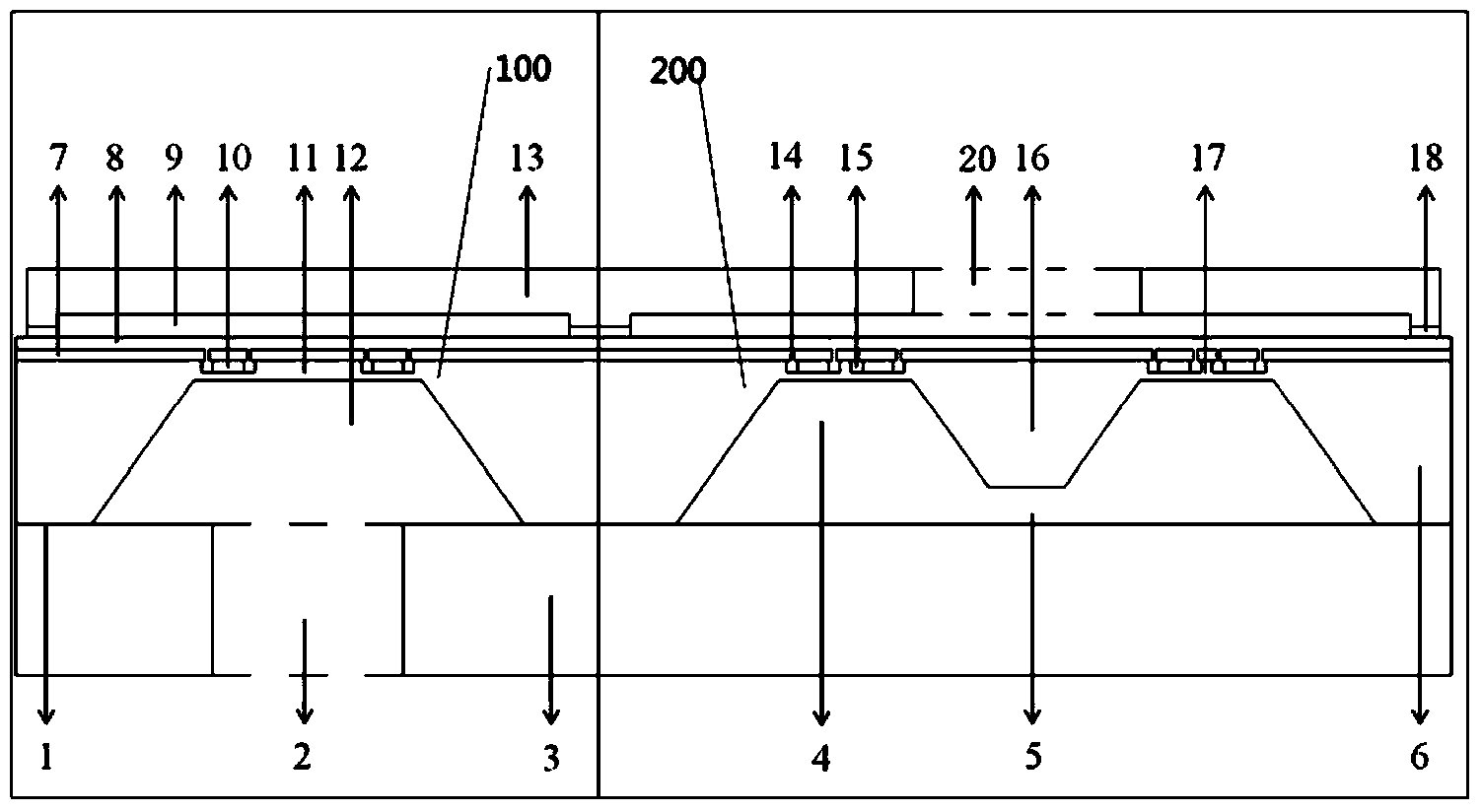

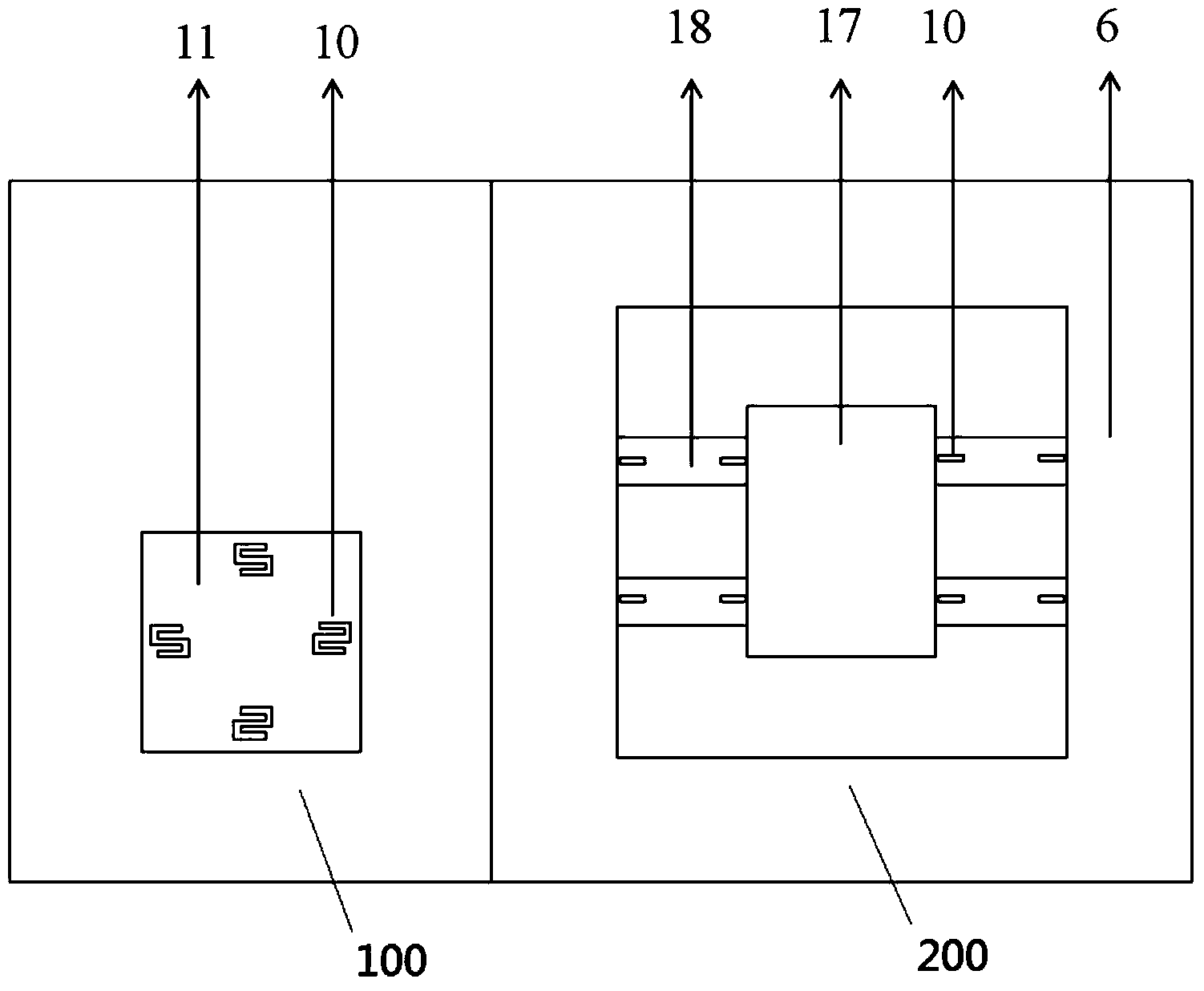

[0035] see figure 1 and figure 2 As shown, this embodiment specifically describes a method for preparing an integrated silicon piezoresistive sensor chip, which includes the following steps:

[0036] 1. Use thermal oxidation to grow silicon dioxide (SiO2) on both sides of a single crystal silicon wafer. 2 ) film layer;

[0037] 2. Perform photolithography in the design area of the silicon wafer square diaphragm 11 and the cantilever beam 17 to form the light boron varistor strip diffusion area;

[0038] 3. Etch the SiO in the diffusion area of the light boron varistor strip 2 film layer;

[0039] 4. Using the diffusion method, the light boron varistor strip 10 is formed;

[0040] 5. Etching off SiO 2 film layer;

[0041] 6. Use thermal oxidation to grow SiO on both sides of the silicon wafer 2 film layer;

[0042] 7. Photolithography is performed on the upper surface of the silicon wafer to form a thick boron resistance ohmic contact area;

[0043] 8. Etch the S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com