A mine-used fiber grating temperature sensor

A temperature sensor, fiber grating technology, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of inability to achieve long-distance detection and application, and achieve high tensile strength, high sealing, and convenience. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

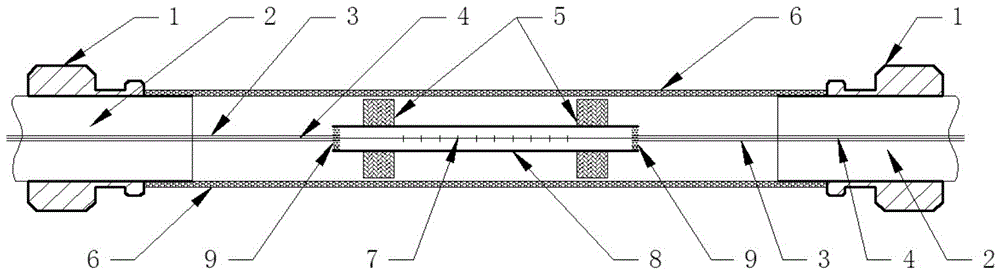

[0016] Such as figure 1 As shown, a mine fiber grating temperature sensor of the present invention includes an outer casing 6, an inner casing 8 and a sensing fiber. In this embodiment, the outer sleeve 6 is a stainless steel tube, and the two ends of the outer tube are respectively connected with ferrule-type tapered thread straight-through pipe joints 1 for connecting with the optical cable 2 . The inner sleeve 8 of this embodiment is a thin metal tube, which is located in the outer sleeve 6, and the two ends of the inner sleeve 8 are respectively sleeved with rubber collars 5, and the outer edge of the rubber collar 5 is configured with the inner wall of the outer sleeve 6. It is used for the radial limit of the inner sleeve 8. The sensing fiber includes a fiber grating 7 and bare fibers 4 at both ends thereof. The fiber grating 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com