Device and method for testing wet expansion coefficient of carbon fiber composite material

A technology of moisture expansion coefficient and composite materials, applied in the direction of using material absorption and weighing, etc., to achieve the effect of wide test range, high resolution and fast test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

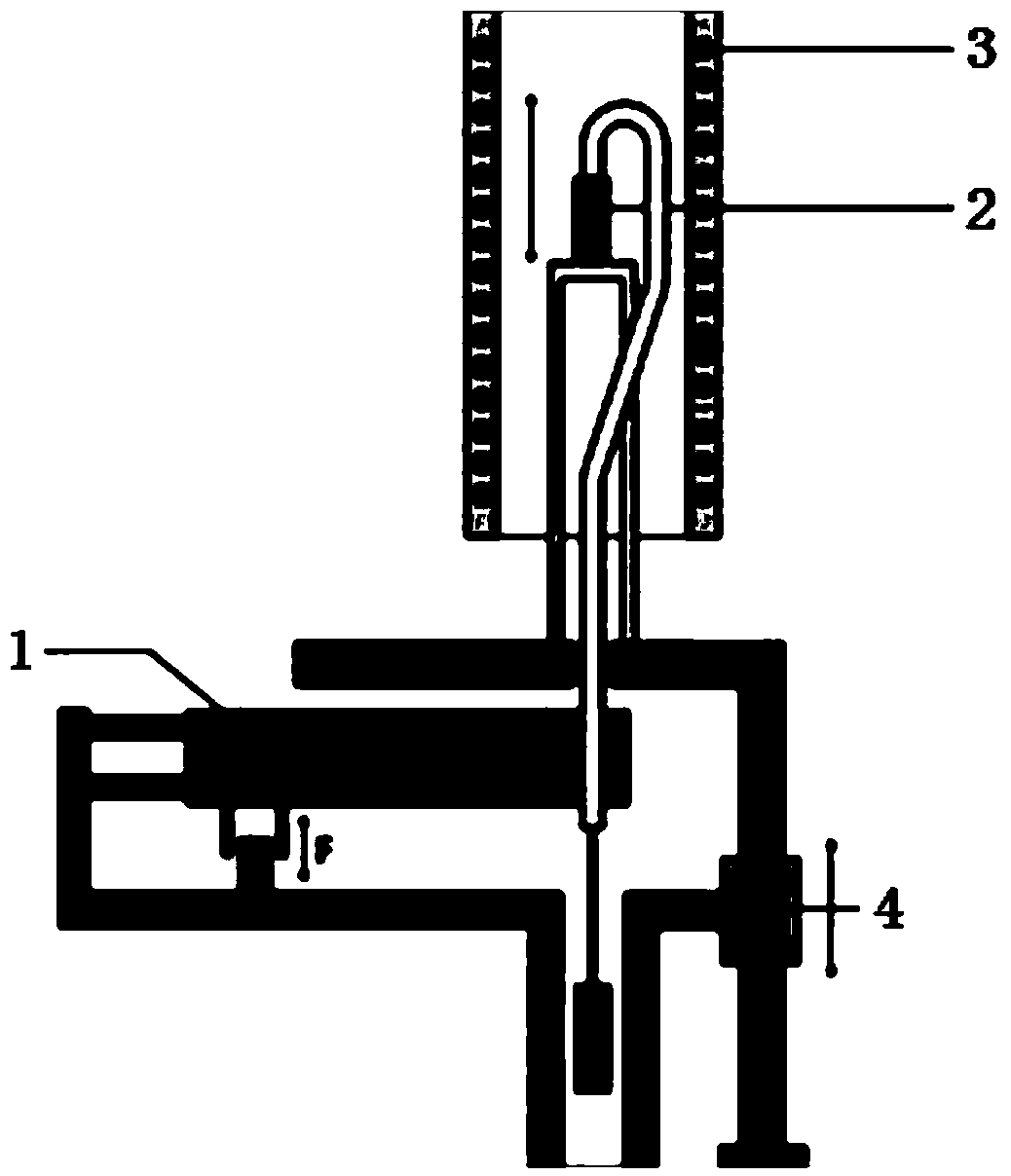

[0033] This embodiment relates to a carbon fiber composite material wet expansion coefficient testing device, such as figure 1 As shown, it consists of the basic unit (high-resolution displacement sensor 4 and force sensor 1), water steam furnace, humidity controller, constant temperature water bath, mass flow meter, etc., among which the thermomechanical analyzer (TMA) is a mature equipment (German resistance Chi), the basic unit is composed of displacement sensor 4, force sensor 1, test chamber (including test furnace 3), push rod, etc. TMA equipment has the characteristics of small measurement sample, wide test range, and high deformation resolution, which fully meets the requirements of carbon fiber composite materials. According to the requirements of the deformation test, this embodiment provides the humidity atmosphere during the test sample 2 by integrating a water steam furnace and equipped with a high-precision humidity sensor in the test room of the TMA equipment.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com