A method for automatic control of the liquid level of a small flotation machine

A liquid level automatic control, flotation machine technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problems of consuming manpower and material resources, affecting the flotation effect, and large fluctuation range of liquid level. Achieve the effect of reducing the probability of burning electronic components, improving reliability and stability, and avoiding excessive instantaneous current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

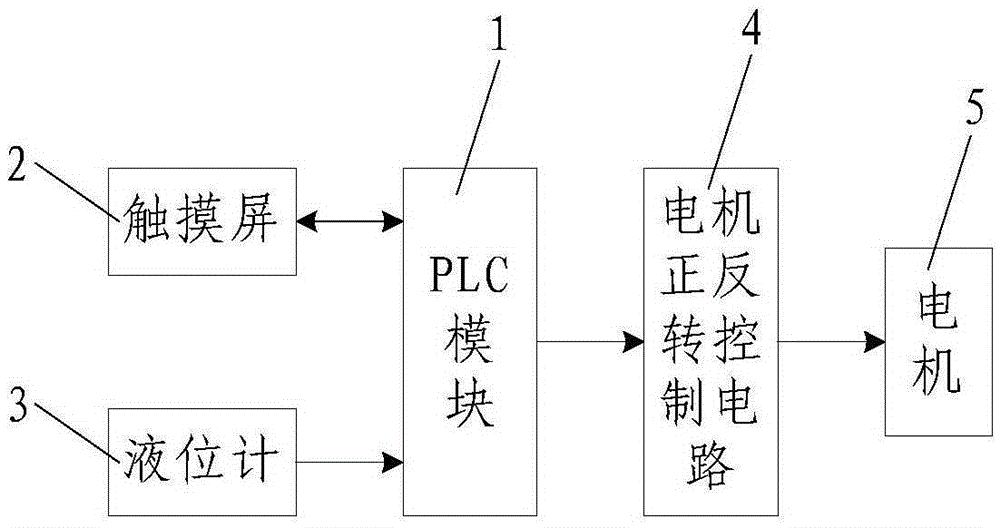

[0036] Such as figure 1 As shown, the automatic control system of the liquid level of the small flotation machine of the present invention includes a PLC module 1 and a touch screen 2 connected with the PLC module 1, and the input terminal of the PLC module 1 is connected to the flotation cell of the flotation machine. The liquid level gauge 3 for real-time detection of the slurry level, the output terminal of the PLC module 1 is connected with a motor forward and reverse control circuit 4 for controlling the forward and reverse of the motor 5 that drives the action of the ore discharge gate valve, and the motor 5 It is connected with the forward and reverse control circuit 4 of the motor.

[0037] In this embodiment, the liquid level gauge 3 is an ultrasonic liquid level gauge. The motor forward and reverse control circuit 4 is composed of relays.

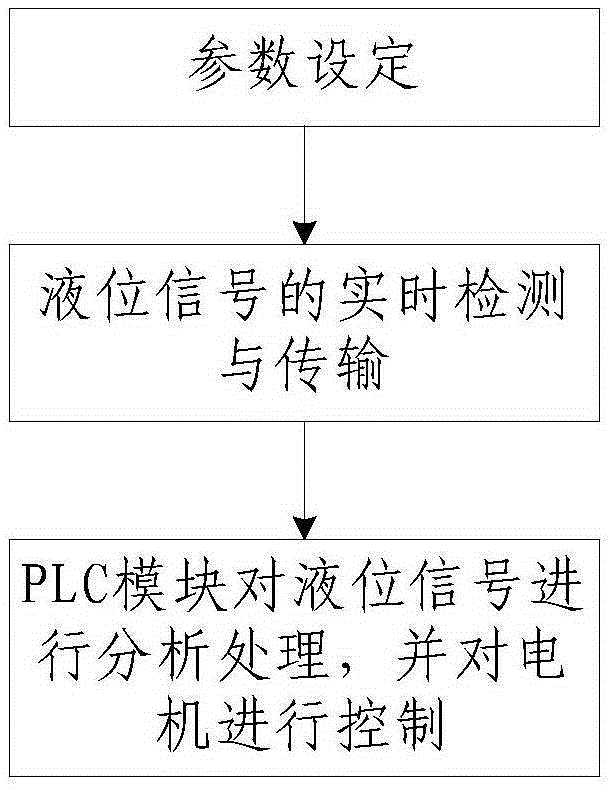

[0038] Such as figure 2 As shown, the liquid level automatic control method of the small flotation machine of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com