Superconducting connector for magnetic resonance superconducting magnet and manufacturing method of superconducting connector

A technology of superconducting joints and superconducting magnets, which is applied in the manufacture/processing of superconductor devices, the usage of superconductor elements, superconducting/high-conducting conductors, etc., and can solve the problems of unstable superconductivity, loss of superconductivity, and critical transmission Current reduction and other issues, to achieve the effect of small attenuation, good anti-interference, good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

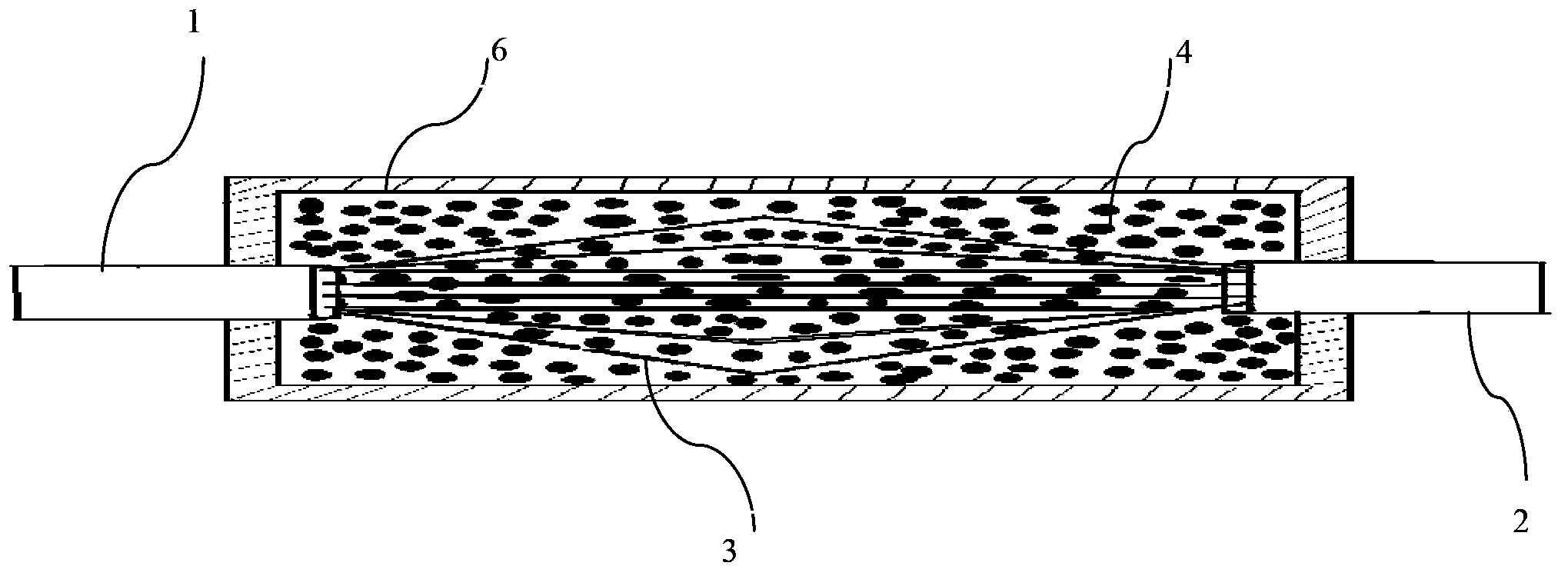

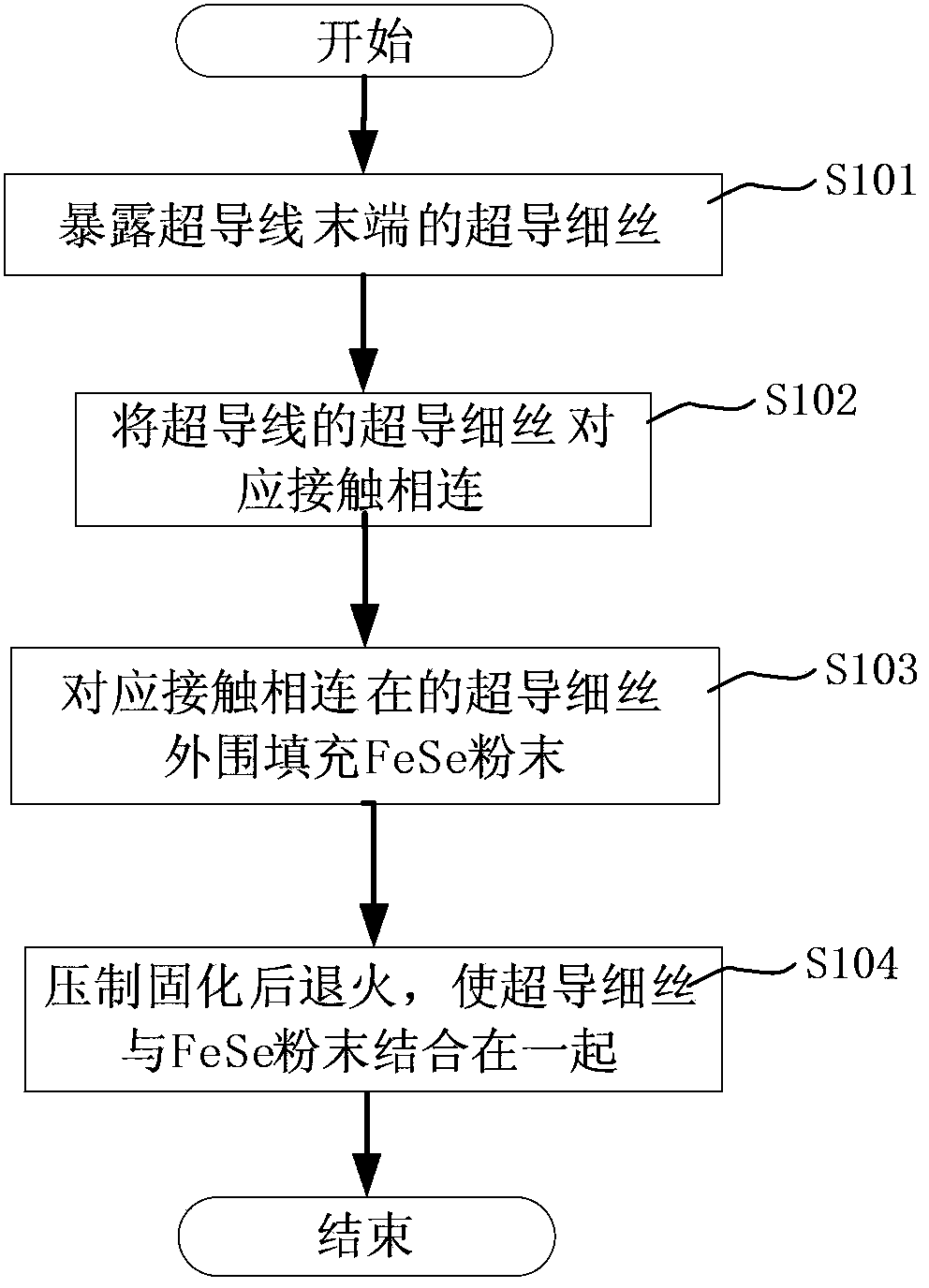

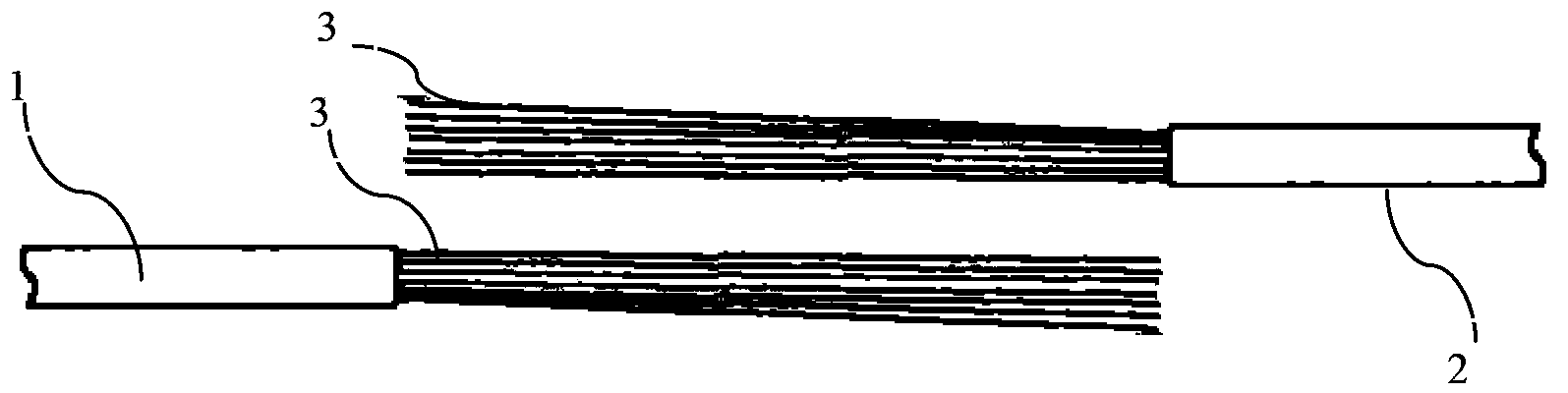

[0038] Such as figure 1As shown, in this embodiment, the superconducting joint used for the magnetic resonance superconducting magnet includes a first superconducting wire 1 and a second superconducting wire 2, and the ends of the two superconducting wires contain a plurality of superconducting filaments 3, The superconducting filament 3 is used as the connection lead wire of the superconducting joint. When the superconducting wire is connected, the superconducting filament 3 is connected by corresponding contact. Preferably, in this embodiment, the superconducting filament 3 is connected by twisting correspondingly, and its outer wrapping There is a FeSe superconducting material 4, the FeSe superconducting material 4 is obtained from FeSe powder 5 through a pressing and curing annealing process, and after the pressing and curing annealing process, the FeSe superconducting material 4 and the superconducting filament 3 are closely combined . In addition to the FeSe superconduc...

Embodiment 2

[0045] like Figure 7 As shown, in this embodiment, the superconducting joint used for the magnetic resonance superconducting magnet includes a first superconducting wire 1 and a second superconducting wire 2, and the ends of the two superconducting wires contain a plurality of superconducting filaments 3, The superconducting filament 3 is used as the connection lead wire of the superconducting joint. When the superconducting wire is connected, the superconducting filament 3 is connected in corresponding contact, and each pair of superconducting filaments connected in corresponding contact can be wrapped with an inert metal thin tube 8 ( Figure 7 Only one of the thin inert metal tubes is shown in the figure), all the thin inert metal tubes 8 can also be wrapped with thick inert metal tubes 9, and FeSe Superconducting materials4. In this embodiment, the exposed part of the superconducting filament 3 can be wrapped with an inert metal thick tube 9, and filled with FeSe materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com