Capacitor containing heat conducting and insulating film

A technology of heat conduction insulation and capacitors, which is applied in the field of capacitors, can solve the problems of circuit or equipment miniaturization of unfavorable cake capacitors, shorten the service life of capacitors, increase the installation space of capacitors, etc. Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

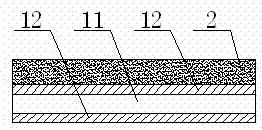

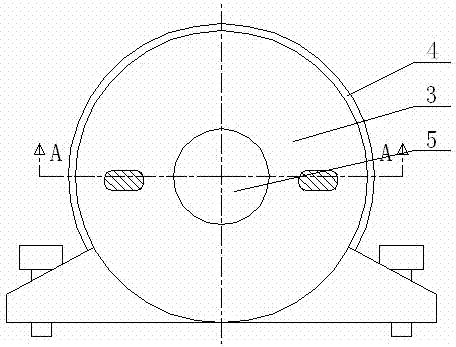

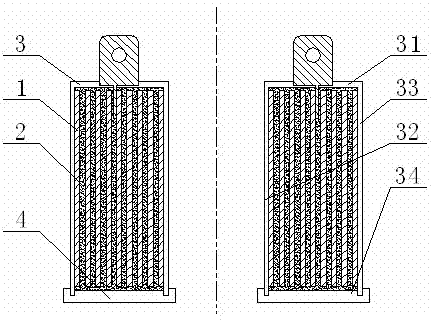

[0017] Such as Figure 1 to Figure 4 Shown is a schematic structural diagram of a capacitor containing a thermally conductive insulating film according to the present invention. A capacitor containing a thermally conductive insulating film according to the present invention includes: a conductive film 1 and a thermally conductive insulating film 2, and also includes a casing 3 and a casing cover 4, and the casing 3 includes an annular side wall 31, a tubular inner wall 32 and a tubular outer wall 33 , the film core is located in the shell 3 and the film core is coaxial with the shell 3, the shell cover 4 is annular and covers the annular opening 34 of the shell 3; the conductive The film 1 includes an insulating medium layer 11 and conductive layers 12 located on both sides of the insulating medium layer 11. The conductive film 1 and the thermally conductive insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com