Motor coordinate transformation control method and system

A technology of coordinate transformation and control system, which is applied in the direction of control system, vector control system, motor generator control, etc., and can solve problems such as shutdown due to fault reporting, insufficient data accuracy, and vibration of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

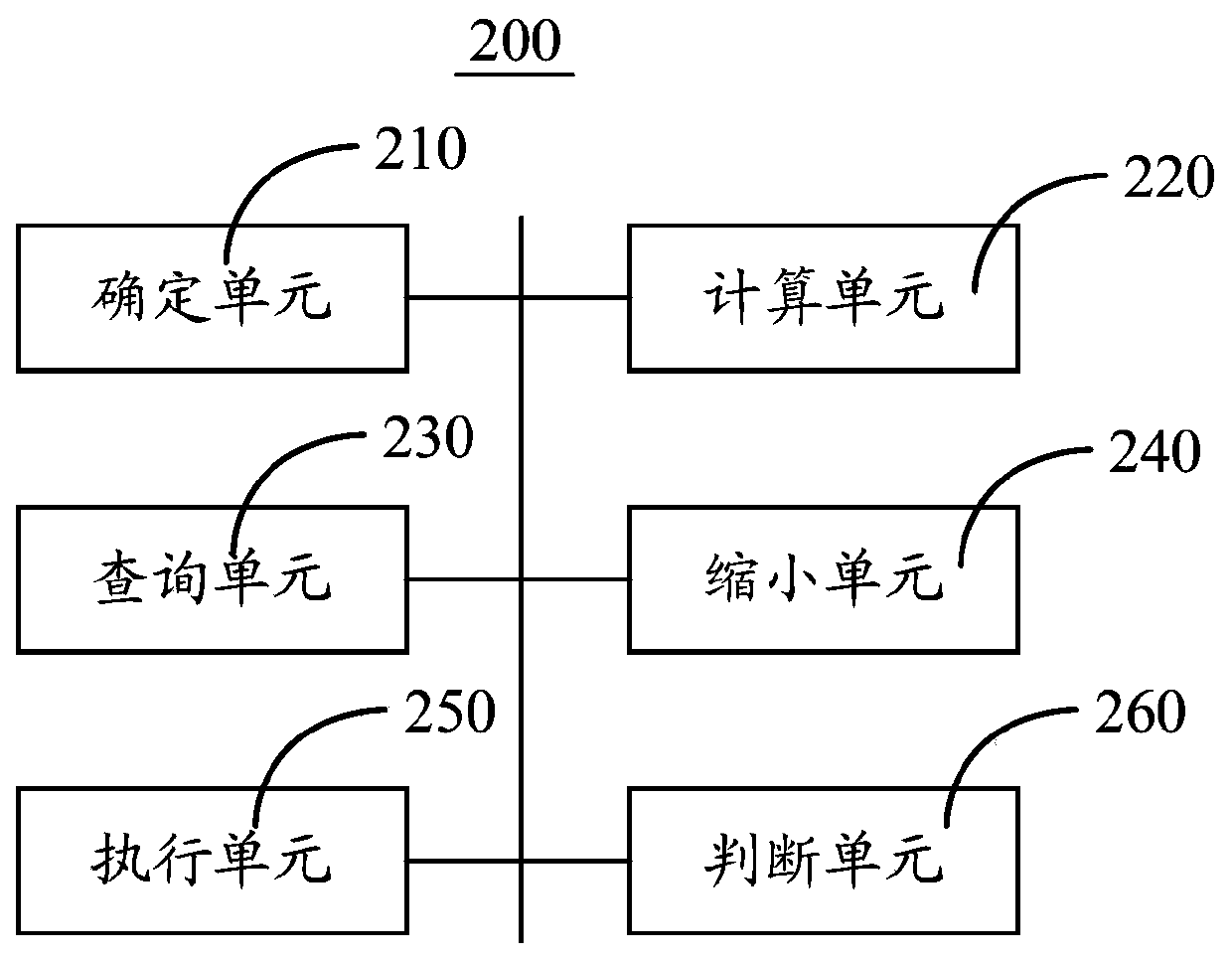

[0069] The embodiment of the present application provides a control method and a control system for the coordinate transformation of the motor, which solves the problem of lack of data accuracy in the prior art, which causes the motor to oscillate, become unstable, or even report a fault and shut down, resulting in out-of-control control The technical problem is to improve the precision of processing data of the single-chip microcomputer and improve the stability of the motor operation.

[0070] The technical solution in the embodiment of the present application is to solve the above problems, and the general idea is as follows:

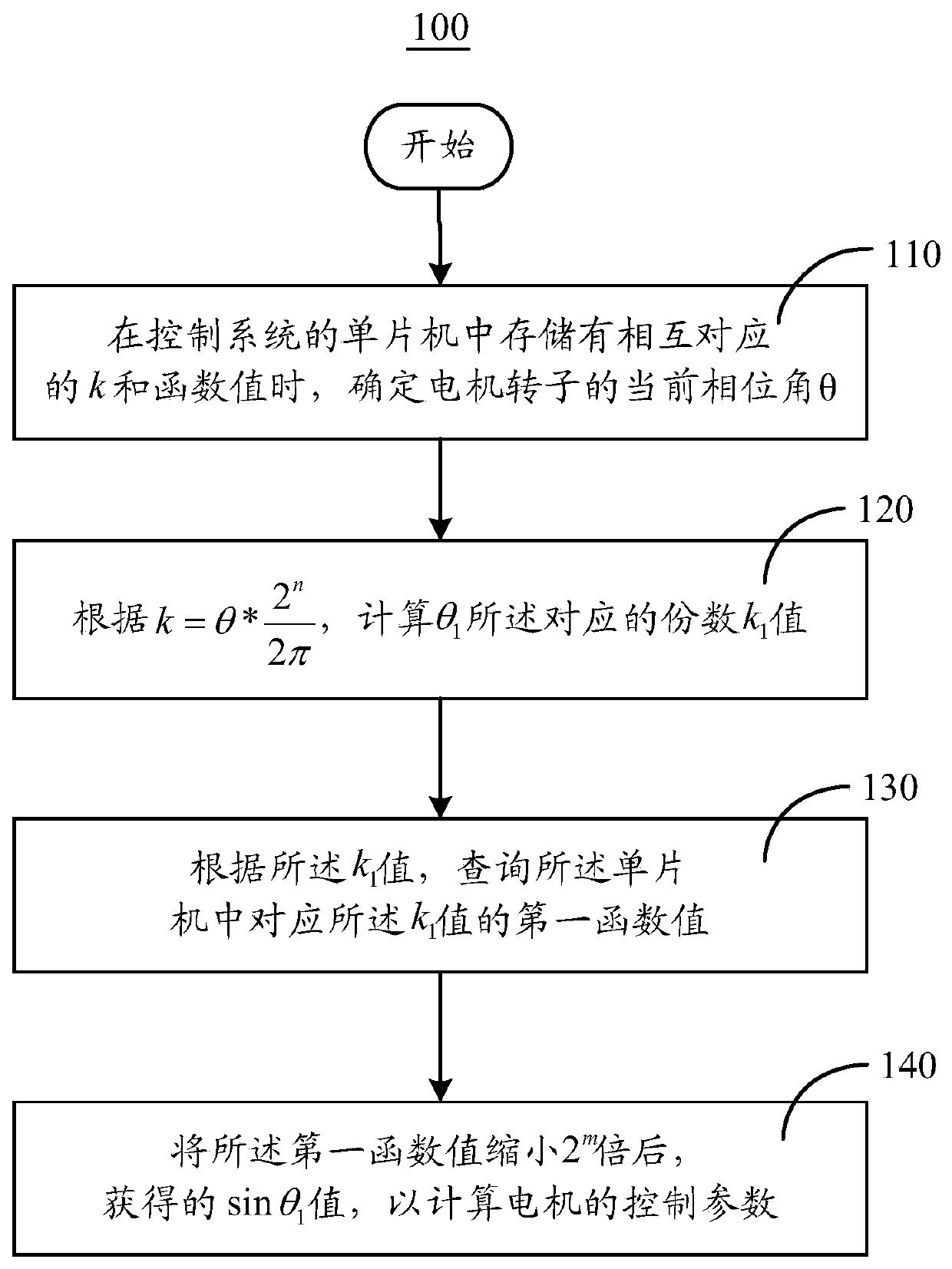

[0071] A control method for motor coordinate transformation, comprising:

[0072] When the corresponding k and function values are stored in the microcontroller of the control system, determine the current phase angle θ of the motor rotor 1 , wherein, the k is the number of parts corresponding to the phase angle θ of the motor rotor, when dividing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com