Vacuum filter with filter-pressing function

A vacuum filter and functional technology, applied in the direction of filtration separation, filtration loop, mobile filter element filter, etc., can solve the problem that the horizontal vacuum belt filter is not easy to feed uniformly, the moisture content of the filter cake is high, and the upper and lower parts are uneven. problems, achieve good economic results, solve difficult dehydration, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

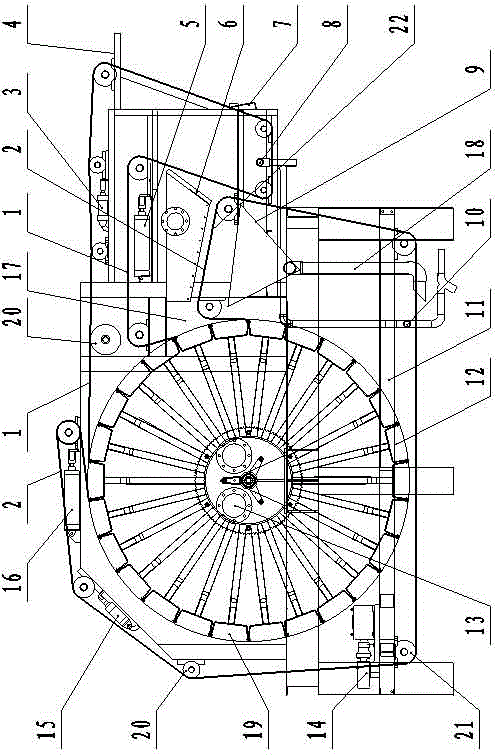

[0037] The present invention will now be further described in detail in conjunction with the accompanying drawings. The accompanying drawings are simplified schematic diagrams, which only schematically illustrate the basic structure of the present invention, and therefore only show the configurations related to the present invention.

[0038] The vacuum filter with filter press function includes a feed system 6 and a filter system, the feed system 6 and the filter system are all arranged on the frame 11, and the filter system includes a vacuum drum 19, a first filter cloth 1 And the second filter cloth 2, the vacuum drum 19 is installed on the frame 11, the vacuum drum 19 rotates under the drive of the drive system 14, and one end of the first filter cloth 1 goes around the vacuum drum 19 and a plurality of first filter cloths. A guide roller 20 is connected with the other end to form a closed loop, and one end of the second filter cloth 2 is connected to the other end after pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com