One-way compression type self-circulation chemical synthesis reactor

A chemical synthesis and reactor technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of large power consumption and achieve the effects of overcoming large power consumption, simple structure, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

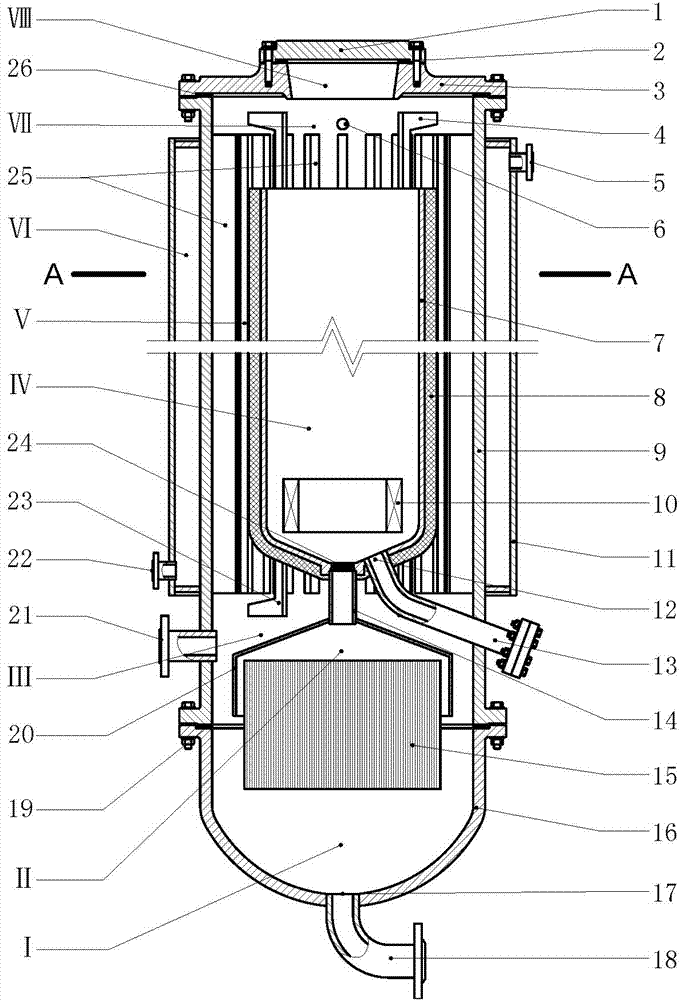

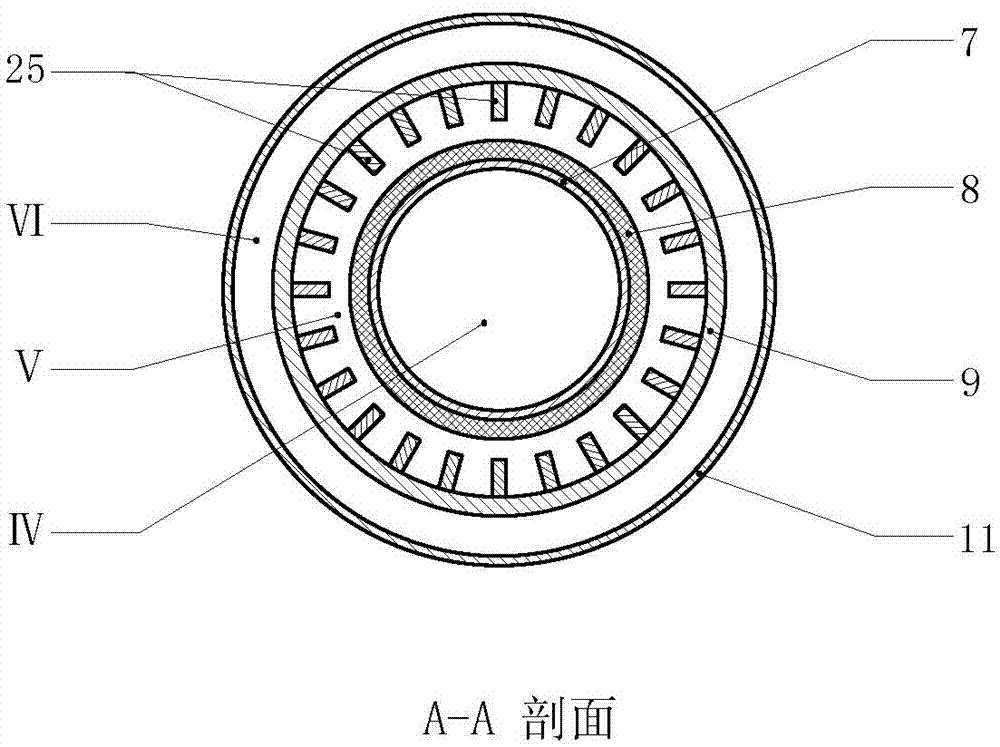

[0019] figure 1 In the shown embodiment, the single-pass compression self-circulation chemical synthesis reactor is mainly composed of a reaction chamber (IV), an upper air chamber (VII), a descending channel (V), a lower air chamber (III), and a cooling water jacket (VI). , cooling ribs (25) and shell (9), wherein the reaction chamber (IV), upper air chamber (VII), descending channel (V) and lower air chamber (III) are set in the inner space of the shell (9) Among them, the cooling water jacket (Ⅵ) surrounds the outer shell of the middle section of the shell (9), the cooling water jacket (VI) is formed by the space between the outer wall (11) and the outer shell of the middle section of the shell (9), and the cooling ribs ( 25) Closely connected to the inner side of the shell in the middle section of the shell (9), the descending passage (Ⅴ) is formed by the space between the inner shell of the middle section of the shell (9) and the reaction chamber wall (7), and the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com