A new type of welding device

A welding device and a new type of technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems such as the inability to consistently eliminate metal stress and deformation at the weld, the deformation strength of the workpiece, and the insignificant effect, so as to eliminate unevenness. Plastic deformation, improved welding strength, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

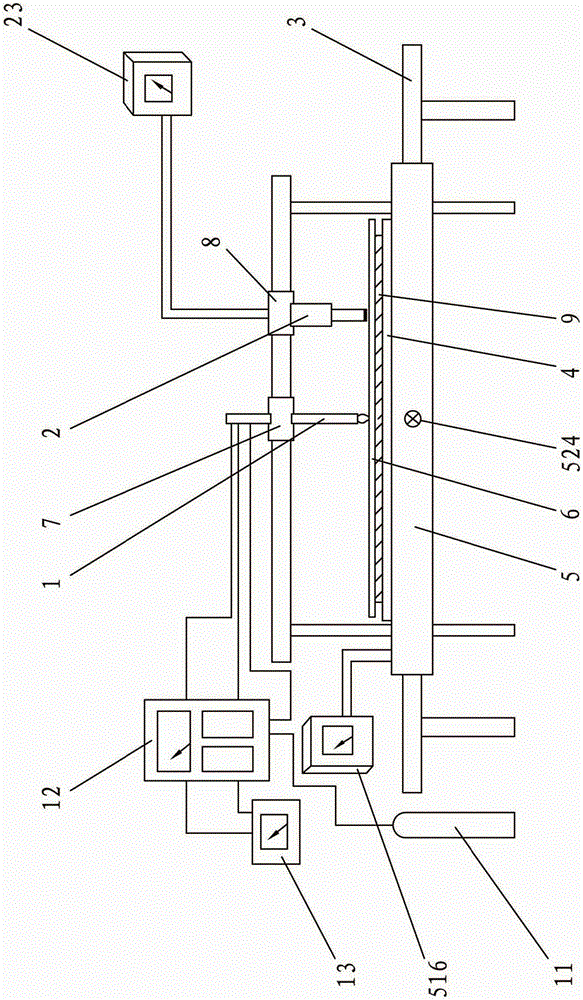

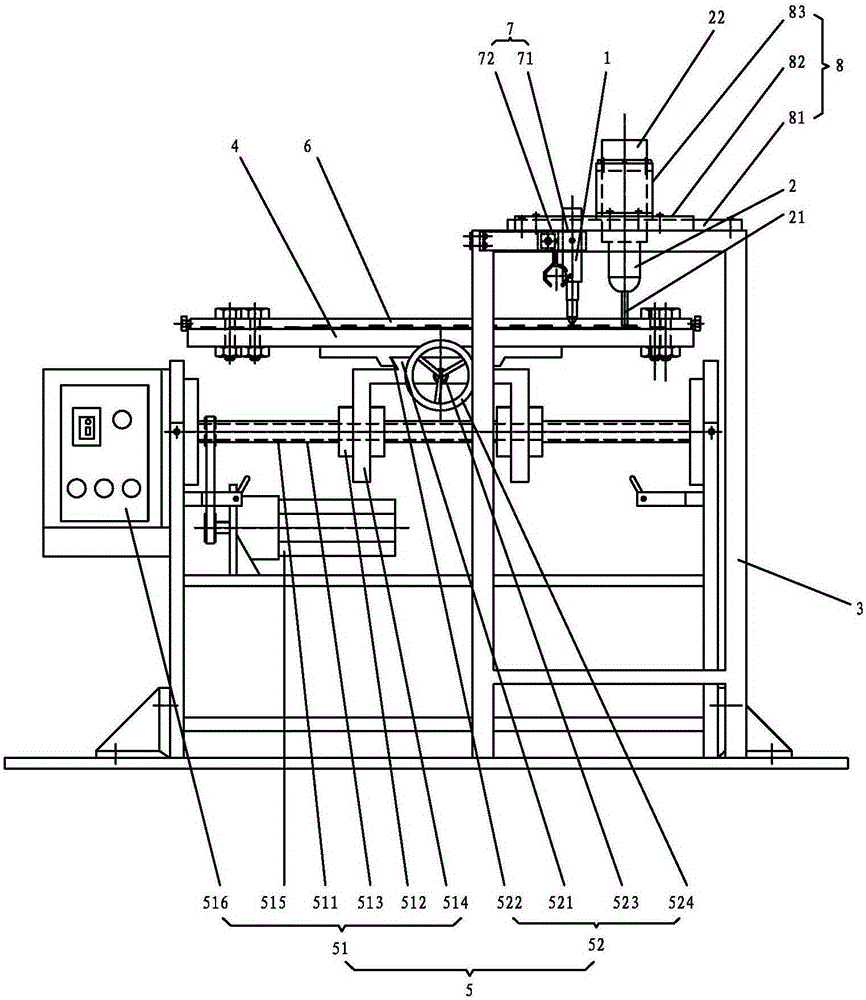

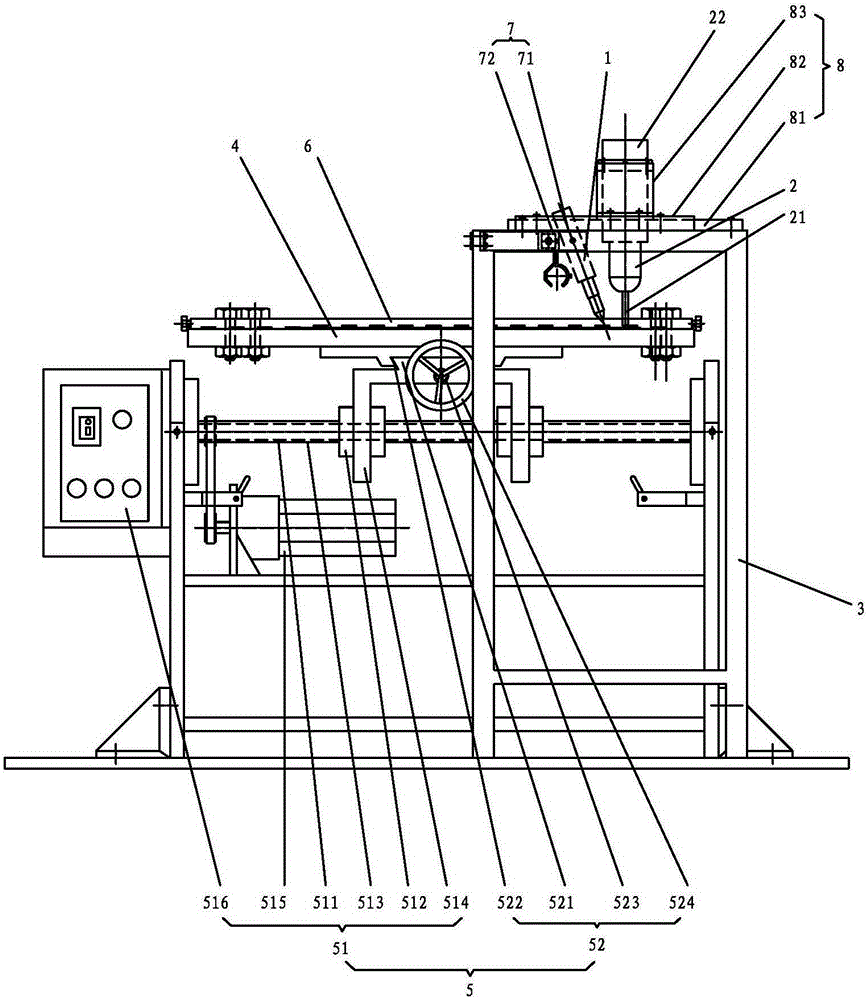

[0052] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

[0053] A kind of novel welding device of the present invention, as Figure 1-5 As shown, it includes a welding torch body 1 and an ultrasonic impact device 2 . Define the direction toward the workpiece 9 as the front, the opposite direction as the rear, the direction of relative movement between the workpiece 9 and the welding torch body 1 as the forward and backward direction (longitudinal direction), and the direction perpendicular to the forward and backward direction in the horizontal plane as the horizontal direction.

[0054] The ultrasonic impact device 2 is arranged at the rear of the welding torch body 1, and performs ultrasonic impact on the high-temperature (above 400°C) weld metal that has solidified on the workpiece 9 and has not yet recovered its strength. The ultrasonic impact device 2 moves synchronously with the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com