Gas storage bag manufactured by waste plastic bags and manufacturing method thereof

A technology of air storage bags and plastic bags, which is applied in the field of air storage bags, can solve problems affecting the earth's environment, and achieve the effects of ensuring practicality and durability, increasing heat preservation performance, good heat preservation and fire protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of method utilizing discarded plastic bag

[0037] A method for utilizing waste plastic bags, comprising the steps of:

[0038] 1. Cleaning plastic bags: sort and clean up the recycled plastic bags. Recycled plastic bags have different dust, oil stains or other dirt in different environments, so it is necessary to classify the recycled plastic bags and then carry out targeted cleaning, and then carry out targeted treatment of the cleaned materials to ensure While using waste plastic bags, it will not pollute the environment.

[0039] 2. Cutting plastic bags: cutting the cleaned plastic bags into plastic sheets 13 according to the principle of maximum utilization, and classifying and storing them for later use. Recycled plastic bags are different types of plastic bags after being used, and most of them are irregular in shape and size. Therefore, different plastic bags need to be cut into single-layer plastic sheets 13 according to the principle of m...

Embodiment 2

[0042] Embodiment 2 A kind of method of making working fabric into thermal insulation air storage bag

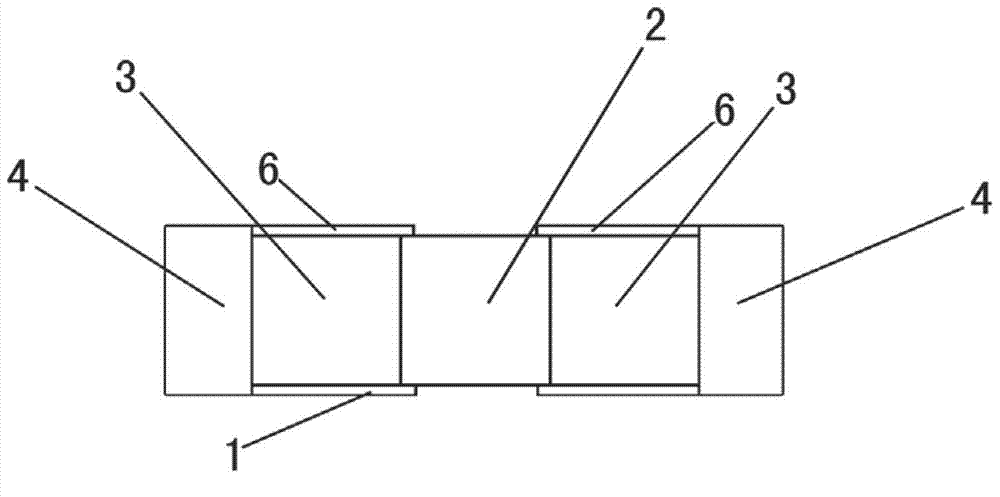

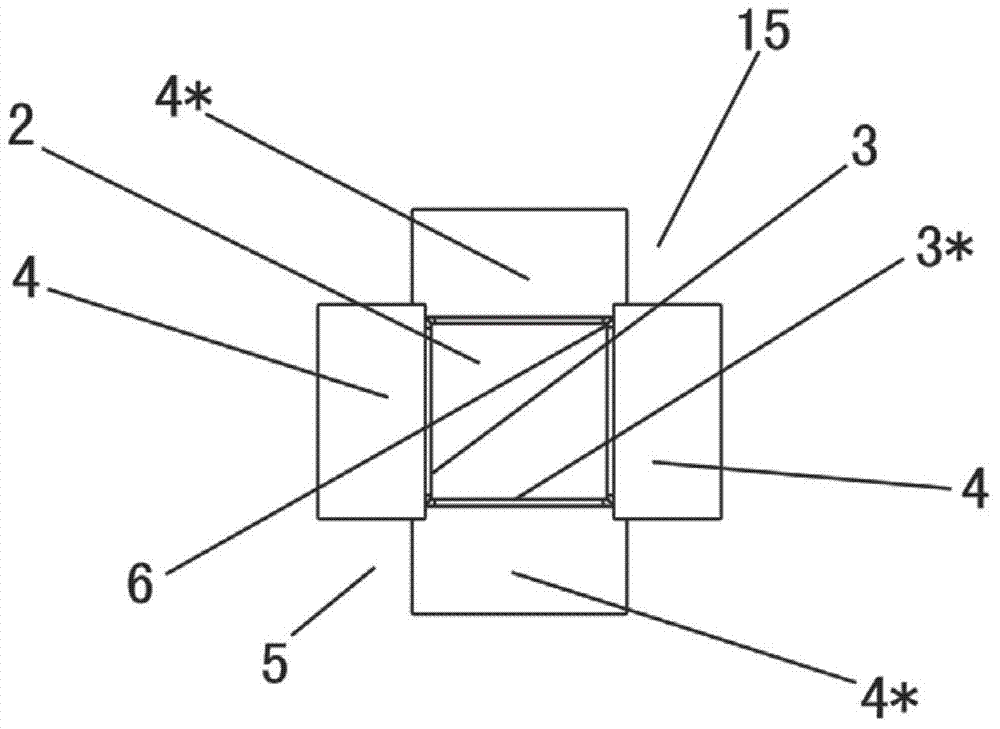

[0043] 1) Making rectangular strips 1: first cut the working fabric 33 into a plurality of rectangular strips 1, and then place the bag cavity wall 3 between the bag edges 4 at both ends of the rectangular strip 1 and the two sides of the bag bottom 2. Cut the fusing edge 6 from the side. The rectangular strip 1 includes two bag sides 4 at both ends, a bag bottom 2 in the middle, and a bag cavity wall 3 between the two bag sides 4 and the bag bottom 2, and the fusing edge 6 is formed on the bag cavity wall. The two sides of 3 are also connected with the bag edge 4 at two ends.

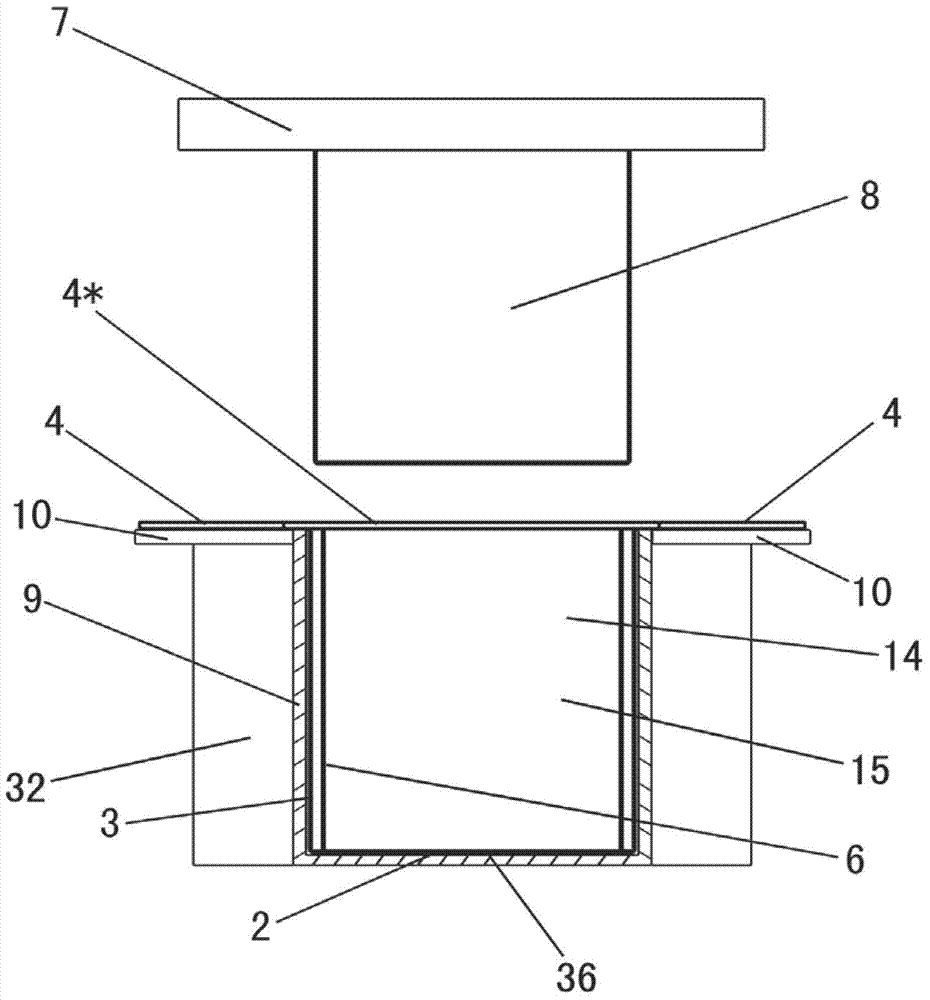

[0044] 2) To make the air storage bag cavity 15: First, put two rectangular strips 1 on the molding unit 9 of the mold 7 to form the prototype 5 of the air storage bag cavity 15 in a horizontal and vertical manner, and then place the shaping unit of the mold 7 8 Put into the forming unit 9 to make ...

Embodiment 3

[0051] Embodiment 3 A kind of thermal insulation air storage bag

[0052] An air storage bag 17 manufactured according to the above method, the air storage bag 17 is used to be filled in a thermal insulation module 38 (not shown), and the interior thereof is filled with carbon dioxide at a certain pressure. Since the air storage bag 17 is stored inside the thermal insulation module 38, it does not matter if the air storage bag 17 made of waste plastic bags is good in airtightness or not.

[0053]The heat preservation module 38 is provided with one or more layers of airtight storage cavities 39, and the storage cavities 39 are provided with horizontal and vertical isolation frameworks 40, and the isolation frameworks 40 isolate the storage cavities 39 into multiple A closed unit cavity 41 for storing the air bag 17. The thermal insulation module 38 is made of gypsum or other materials, and it is combined in a layer-by-layer manner to facilitate the unit cavity 40 in the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com