Combination method for treating pickled vegetable processing wastewater based on anaerobic ammonia oxidation

A technology of anaerobic ammonium oxidation and pickled mustard wastewater, which is applied in anaerobic digestion treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of large energy consumption, high operating costs, and high infrastructure costs, and achieve good results Salinity impact resistance, low energy consumption, and low sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

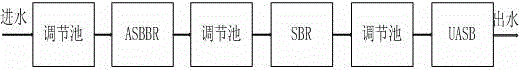

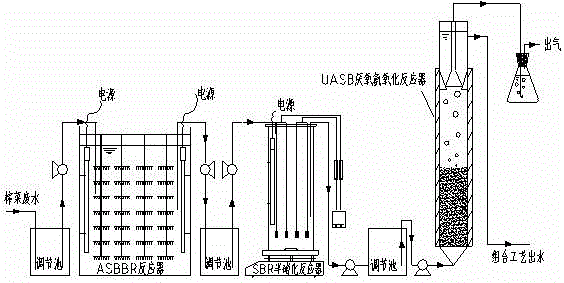

[0024] The invention adopts the combination method of anaerobic ASBBR-seminitrosation SBR-anammox UASB to treat pickled mustard wastewater, can treat mustard mustard wastewater with a salinity (calculated as NaCl) less than 3.5%, can adapt to the salinity of mustard mustard wastewater, and can simultaneously Efficiently remove high-concentration organic matter and high-concentration nitrogen in mustard mustard wastewater.

[0025] The present invention consists of the following steps, which can be referred to simultaneously figure 1 :

[0026] (1) Mustard mustard wastewater first enters the first adjustment tank for pH control, and the pH is adjusted to 6.5-8.0 to meet the water inlet requirements of the ASBBR reactor.

[0027] (2) The effluent of the first regulating tank enters the ASBBR reactor for anaerobic treatment, and the COD removal rate of the effluent of the ASBBR reactor is controlled to be above 80%, so as to convert organic nitrogen into ammonia nitrogen. Soft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com