Slag compound activating grinding aid and preparation method thereof

A compound activation and grinding aid technology, which is applied in the field of cement production and processing, can solve the problems of insufficient activity excitation and low powder efficiency, and achieve the effects of avoiding pollution, stable application performance, and increased activity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

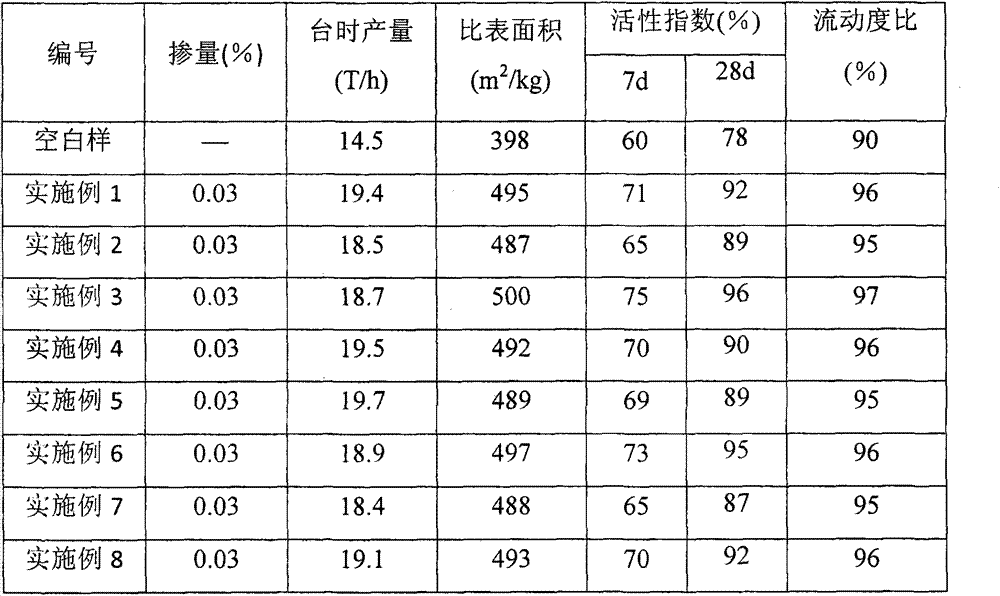

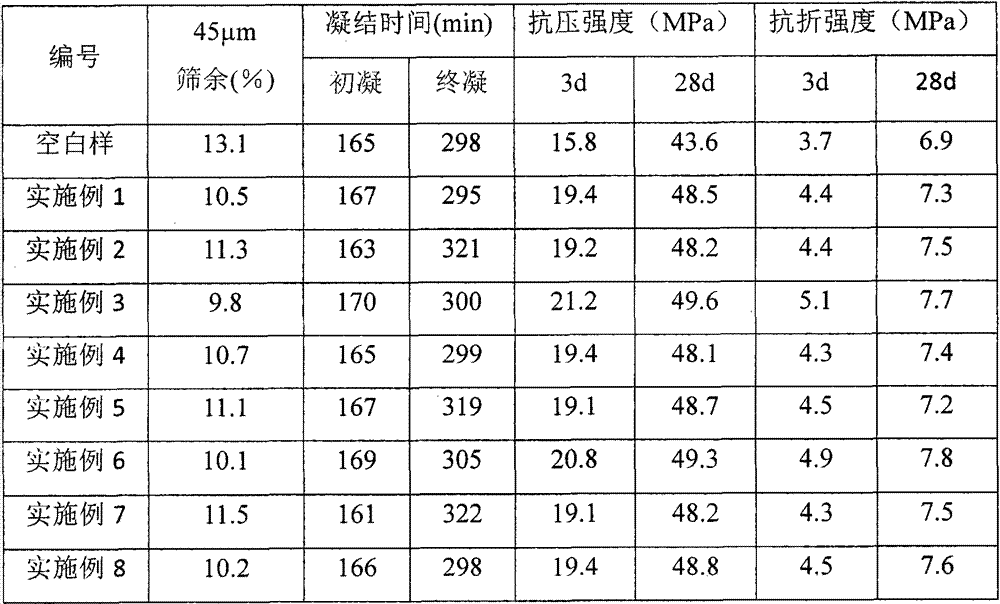

Examples

example 1

[0020] The composition and mass ratio of the slag compound activated grinding aid are 5% water glass, 5% sodium carbonate, 5% sodium rosinate, 20% betaine mother liquor, 12% polyethylene glycol, 2% molasses, water-soluble polymer 10% of food and the balance of water.

example 2

[0022] The composition and mass ratio of the slag composite activated grinding aid are 8% water glass, 8% sodium carbonate, 3% sodium rosinate, 18% betaine mother liquor, 12% polyoxyethylene octylphenol ether, 2% molasses, 8% water-soluble polymer and the balance water.

example 3

[0024] The composition and mass ratio of the slag compound activated grinding aid are 10% of water glass, 10% of sodium carbonate, 7% of sodium rosinate, 12% of betaine mother liquor, 7% of sorbitan monostearate, and 2% of molasses. %, water-soluble polymer 8% and the balance water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com