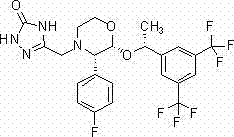

Method for preparing 2-(2-chloro-1-ethidene)hydrazide methyl formate

A technology of methyl hydrazide formate and chloroacetonitrile, which is applied in the field of synthesis of the antiemetic drug aprepitant intermediate 2-methyl hydrazide formate, can solve the problems of low purity, high energy consumption, and long time consumption, and achieve The effect of high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Under nitrogen protection, 50 g (0.67 mol) of chloroacetonitrile and 200 ml of methanol were successively added into a 1000 ml three-necked flask, and cooled to 0 °C. Dissolve 1g of sodium methoxide in 50ml of methanol and slowly drop it into the reaction flask. After the dropwise addition was completed, the mixture was raised to room temperature and stirred for 30 minutes. 1.06 ml of glacial acetic acid were added, and then a solution of 39 g (0.43 mol) of methyl carbazate in 250 ml of methanol was added dropwise to the resulting mixture. After the dropwise addition was complete, stirring was continued for 30 minutes.

[0024] Concentrate the reaction solution under reduced pressure until it is nearly dry, add 1000ml of acetone, stir and beat at room temperature for 30min, filter to obtain a light yellow solid, and dry the solid at 50°C with air blowing to obtain 70.1g of 2-(2-chloro-1-ethylidene)hydrazide formic acid methyl Esters, yield: 93.1%, HPLC purity 99....

Embodiment 2

[0026] Under nitrogen protection, 50 g (0.67 mol) of chloroacetonitrile and 200 ml of methanol were successively added into a 1000 ml three-necked flask, and cooled to 0 °C. Dissolve 1g of sodium methoxide in 50ml of methanol and slowly drop it into the reaction flask. After the dropwise addition was completed, the mixture was raised to room temperature and stirred for 30 minutes. 1.06 ml of glacial acetic acid were added, and then a solution of 39 g (0.43 mol) of methyl carbazate in 250 ml of methanol was added dropwise to the resulting mixture. After the dropwise addition was complete, stirring was continued for 30 minutes.

[0027] Concentrate the reaction solution under reduced pressure until nearly dry, add 500ml of acetone, stir and beat at room temperature for 2 minutes, filter to obtain a light yellow solid, and dry the solid at 50°C with air blast to obtain 69.5g of 2-(2-chloro-1-ethylidene)hydrazide formic acid Methyl ester, yield: 93.0%, HPLC purity 99.5%.

Embodiment 3

[0029] Under nitrogen protection, 50 g (0.67 mol) of chloroacetonitrile and 200 ml of methanol were successively added into a 1000 ml three-necked flask, and cooled to 0 °C. Dissolve 1g of sodium methoxide in 50ml of methanol and slowly drop it into the reaction flask. After the dropwise addition was completed, the mixture was raised to room temperature and stirred for 30 minutes. 1.06 ml of glacial acetic acid were added, and then a solution of 39 g (0.43 mol) of methyl carbazate in 250 ml of methanol was added dropwise to the resulting mixture. After the dropwise addition was complete, stirring was continued for 30 minutes.

[0030] Add 500ml of acetone dropwise to the above reaction solution, stir while adding dropwise, continue to stir and crystallize at -10~0°C after the dropwise addition, start to crystallize after 1h, keep stirring for 40~60min, filter to obtain a light yellow solid, solid Air-dried at 50°C to obtain 38.1 g of methyl 2-(2-chloro-1-ethylene)hydrazid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com