PVC (polyvinyl chloride) foaming aluminum-plastic building template

A technology of building formwork and foamed aluminum, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of poor strength and restrictions on popularization and application, so as to increase the number of repeated uses, improve strength, and enhance impact resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

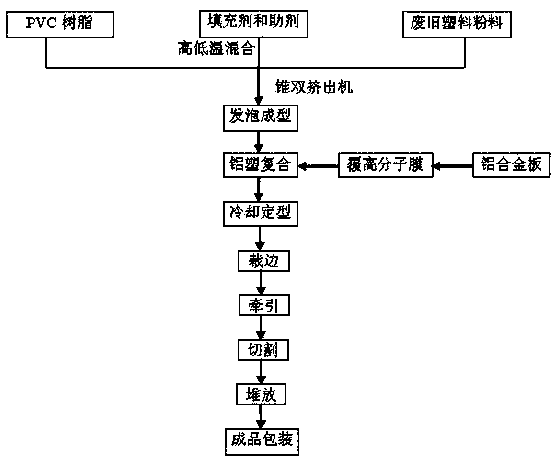

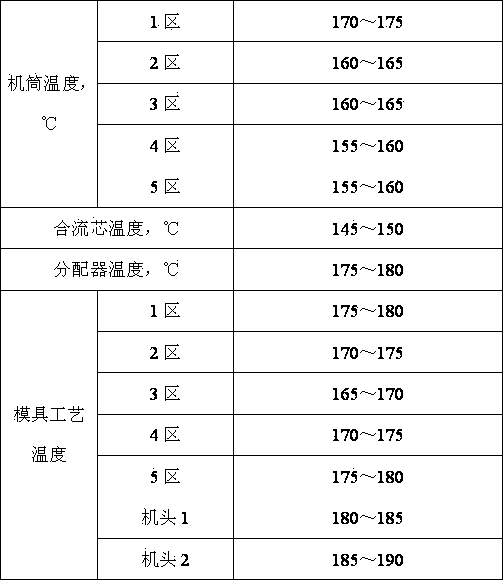

Method used

Image

Examples

Embodiment Construction

[0012] A PVC foamed aluminum-plastic building template, which is composed of an upper aluminum alloy plate surface layer, a lower aluminum alloy plate surface layer and a middle foam core layer, the thickness of the middle foam core layer is 14mm, and the density is 0.60-0.65g / cm 3 , the surface layer of the upper aluminum alloy plate and the surface layer of the lower aluminum alloy plate have a thickness of 0.5mm, covering the upper and lower surfaces of the middle foam core layer.

[0013] The components and parts by weight of the middle foam core layer are: SG-5 type PVC resin 25, 50 mesh PVC waste powder 60, 1000 mesh light calcium carbonate 13, AC foaming agent 0.3, NC foaming agent 0.4 , Foam regulator (ACR-401) 5, composite heat stabilizer 2.8, paraffin wax 0.5, oxidized polyethylene wax OA-60.2, polyethylene wax (PE wax) 0.6, CPE-135A4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com