Double tooth airtight thread

A gas-sealed and tooth-shaped technology, which is applied to drilling equipment, earthwork drilling, drill pipes, etc., can solve the problems of easily damaged oil and gas seals, failures, etc. buckle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

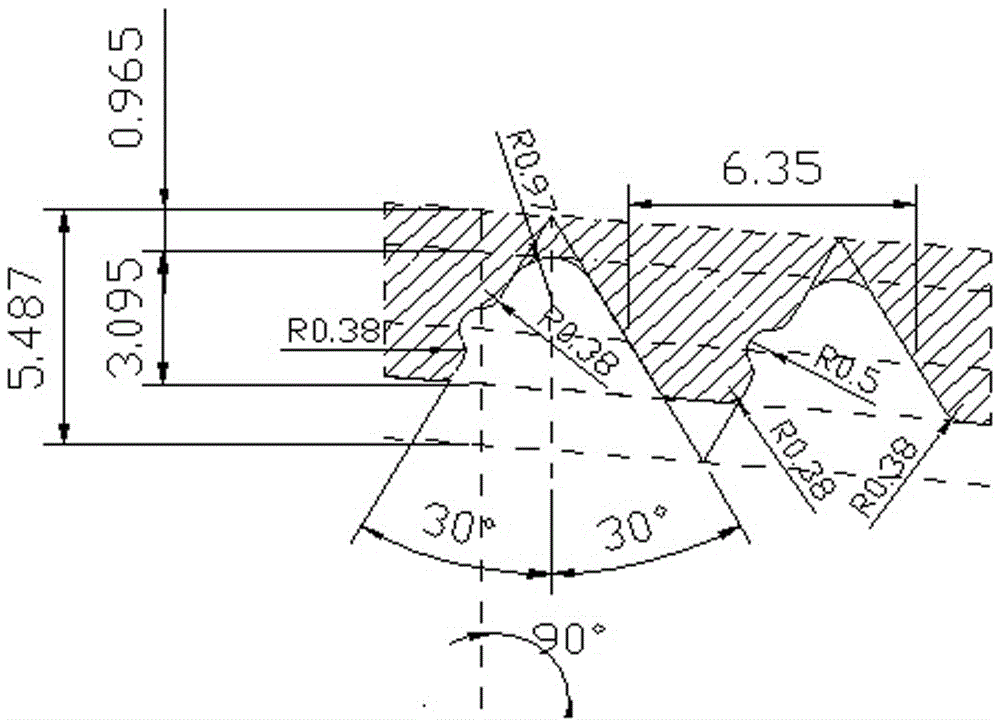

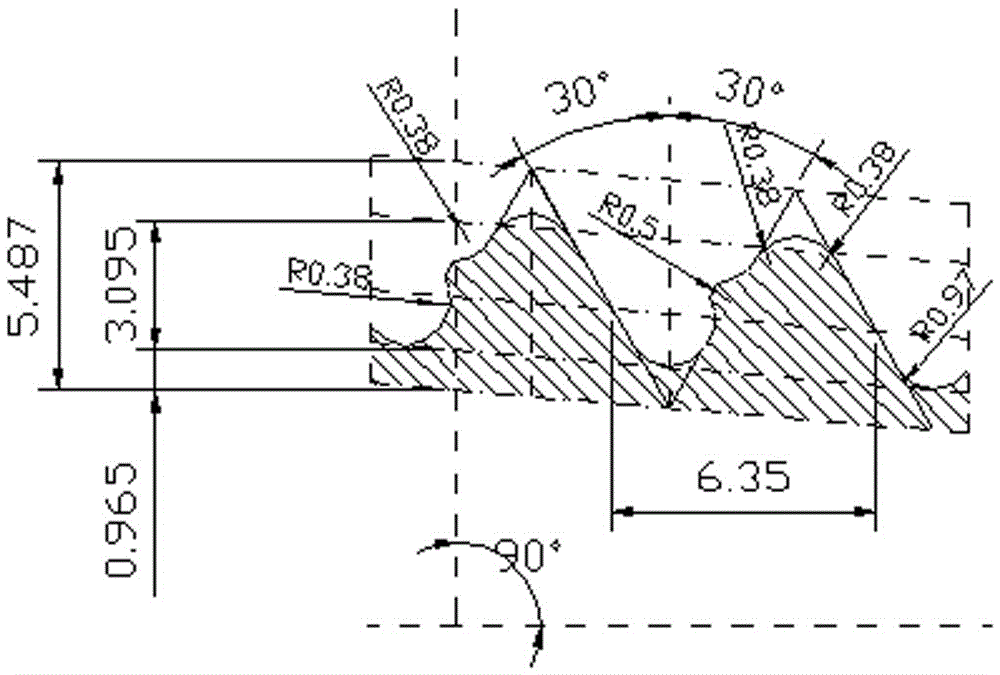

[0020] like figure 1 The shown drill tool has a male joint and a female joint at both ends; the male joint and the female joint are double-tooth air-tight threads, such as figure 2 , image 3 As shown, the thread of the male joint and the female joint is a tapered triangular thread, the tooth angle is 60°, and the internal and external threads have three sealing surfaces respectively: the shoulder surface, the end surface has a 15° angle cone surface seal, the tooth The sealing groove R formed by the convex arc sealing surface and the concave arc sealing surface on the side surface 0 -0.02 and R +0.02 0 , The tooth height of the thread is 3.095mm, the tooth top width is 1.66mm, the pitch is 4 teeth / inch, the taper is 1:6, and the sealing groove R=0.5mm.

[0021] like Figure 4 As shown, under the pretightening force of 9000N.m~12000N.m, the thread pair is tightly screwed. At this time, the gap between the major diameter of the external thread and the major diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com