Silver thin film composited carbon sealing ring and preparation method thereof

A sealing ring and silver thin film technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of sealing ring sealing effect, cold resistance, heat resistance, etc., and achieve simple structure, reasonable design and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

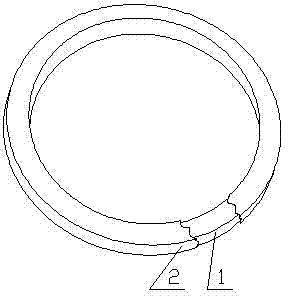

Image

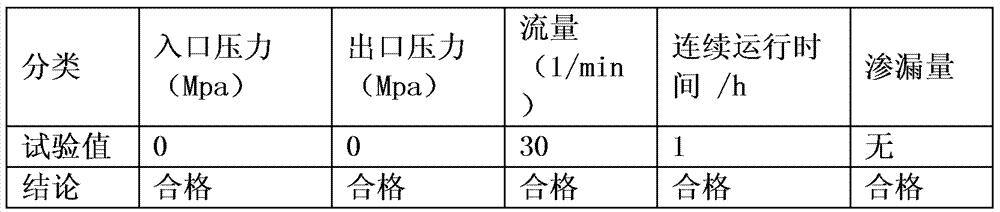

Examples

Embodiment 1

[0017] A carbon sealing ring with a composite silver film, which comprises: a carbon ring 1, the surface of the carbon ring is compounded with a silver film 2, the inner diameter of the carbon ring is ф10cm, and the outer diameter of the carbon ring is ф12cmm.

Embodiment 2

[0019] A preparation method of a carbon sealing ring of a composite silver film, the first step, adding graphite powder into a mold of a forming machine, pressurizing to form a carbon ring with an inner diameter of ф10cm and an outer diameter of ф12cmm;

[0020] The second step is to carry out surface polishing and other treatments on the carbon ring, and then put it into the mold of the high-pressure vacuum impregnation furnace;

[0021] The third step is to put the solid silver into the crucible in the high-pressure vacuum impregnation furnace, heat it to melt, and at the same time, vacuumize the high-pressure vacuum impregnation furnace, and preheat the carbon ring;

[0022] In the fourth step, when the temperature in the high-pressure vacuum impregnation furnace is 1000-1100°C and the pressure is 20-25Mpa, the outlet of the crucible is aligned with the inlet of the mold pipeline equipped with a carbon ring, so that the molten silver liquid Enter the mold through the pipeli...

Embodiment 3

[0024] According to the preparation method of the carbon sealing ring of the composite silver film described in Example 2, the purity of the graphite powder is above 99%.

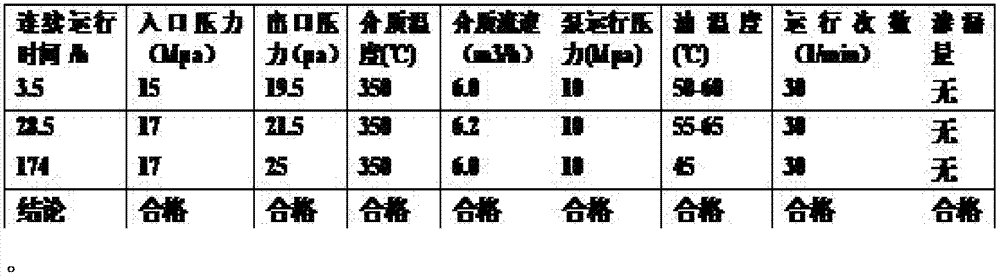

[0025] The determination of the carbon seal ring preparation process of the described composite silver film:

[0026] In the preparation process of the carbon sealing ring of the composite silver film, different process parameters directly affect the performance of the carbon sealing ring of the composite silver film, especially the generation of the interface constitutes an important influence. The interface formed by the carbon sealing ring of the composite silver film is mainly wetted, and a small part of the reactive interface exists. When only considering the impregnation effect of graphite materials, the main influencing factors are:

[0027] 1) Metal silver melt temperature: the higher the temperature, the better the fluidity, and the easier it is to fill into the deep layer of the carbon ring, but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com