Pinhole defect detection system and detection method of isolation film

A technology of defect detection and isolation film, which is applied in the direction of optical defect/defect, can solve the problem of difficult to distinguish pinhole defect and rubber particle defect, and achieve the effect of avoiding explosion and reducing the probability of false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

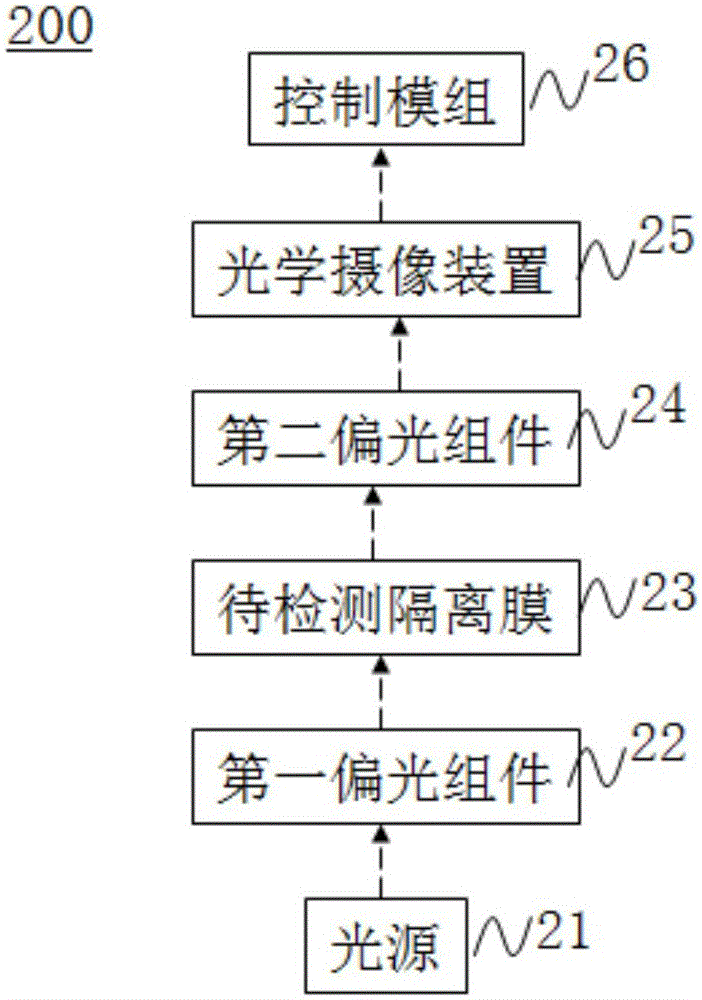

[0023] Please refer to figure 2 , figure 2 It is a schematic diagram of a pinhole defect detection system 200 for an isolation film according to an embodiment of the present invention. The detection system 200 includes a light source 21 , a first polarizer component 22 , a second polarizer component 24 , an optical camera device 25 and a control module 26 . The optical camera device 25 is used to capture the detection image of the detection area corresponding to the point to be measured on the isolation film 23 to be detected that includes the point to be tested; the light source 21 provides light that travels toward the optical camera device 25; the first polarizing assembly 22 has a second An optical axis, which can be a polarizer or a metal grating, is located ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com