Method and device for testing acoustic performance of ultrathin polyethylene test sample

A polyethylene and ultrasonic testing technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of smooth thickness, difficult to achieve sample surface, difficult to measure ultrasonic waves, etc., and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

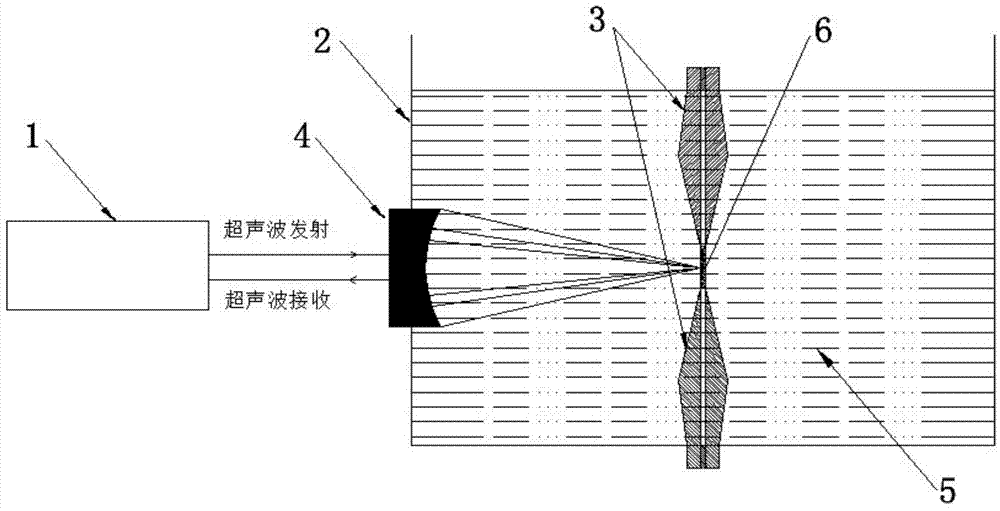

[0024] figure 1 The pulse reflection device based on liquid immersion focusing technology includes an ultrasonic detector 1, a test container, a clamping device 3 and a focusing probe 4 for measuring the acoustic impedance of a sample 6 to be tested. The ultrasonic detector 1 is arranged on the outside of the test container, the test container is a device with an open top, a through hole is provided on one side of the test container, the focusing probe 4 is embedded in the through hole, and the focusing probe 4 can receive the ultrasonic detector 1 After the signal, a focused sound beam is sent out, and then the echo signal is received, and the echo signal is sent back to the ultrasonic detector 1; the clamping device 3 is installed on the testing device, and is used to fix the sample 6 to be tested in the testing device , and the sample 6 to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com