A kind of photoresist wall forming method

A molding method and photoresist technology, applied in optics, components for photomechanical processing, instruments, etc., can solve the problems of photoresist wall delamination, strong water absorption, large thermal expansion coefficient, etc., to reduce delamination and Release, low hygroscopicity, and strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

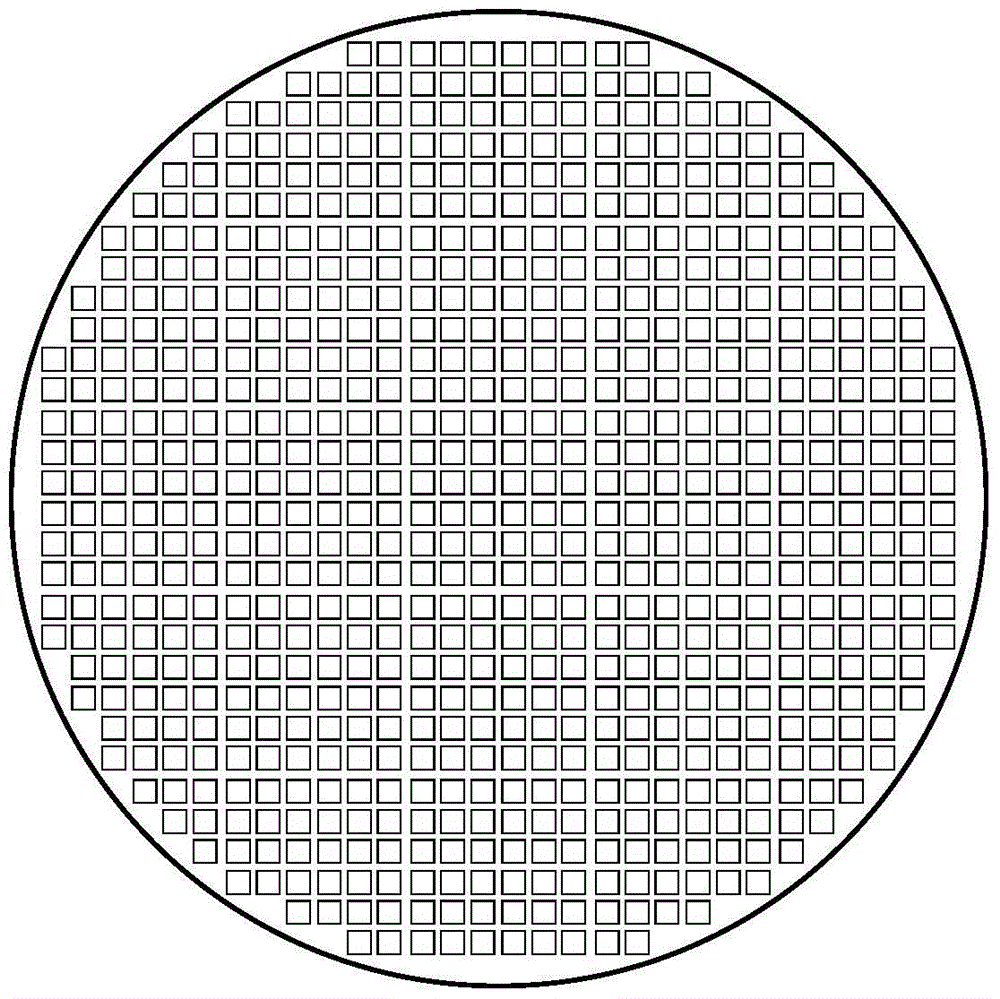

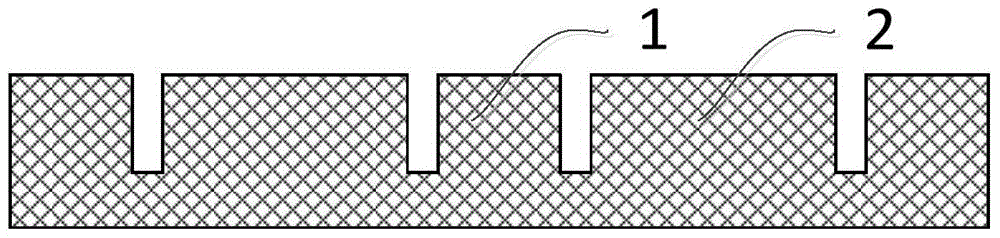

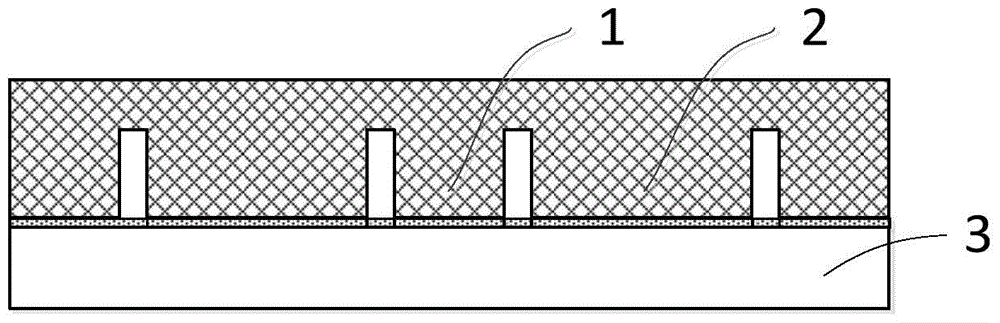

[0032] 1. Use injection molding technology to form a flat plate, such as figure 2 As shown, the front of the flat plate has a first boss 1 and a second boss 2, the first boss 1 is grid-like, and each grid has a second boss 2, and the first boss 1 It is separated from the second boss 2 by a groove, and the first boss 1 and the second boss 2 have the same height. The flatness of the surface of the first boss 1 is less than 5 microns. The flat plate can adopt encapsulating resins such as phenolic resin, benzoxazine resin, cyanic acid resin, polyimide, bismaleimide, polyphenylene ether, polyetheretherketone and modified materials thereof. Taking glass fiber-reinforced epoxy resin as an example, the maximum temperature it can withstand after curing exceeds 260 degrees Celsius, which exceeds the maximum temperature of 260 degrees Celsius for image sensor reflow soldering a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com