Frozen kumquat juice and production method thereof

A production method and technology for freezing kumquats, which are applied in the fields of food freezing, food processing, food science, etc., can solve problems such as unsuitable peeling, and achieve the effect of reducing pungency and pungency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

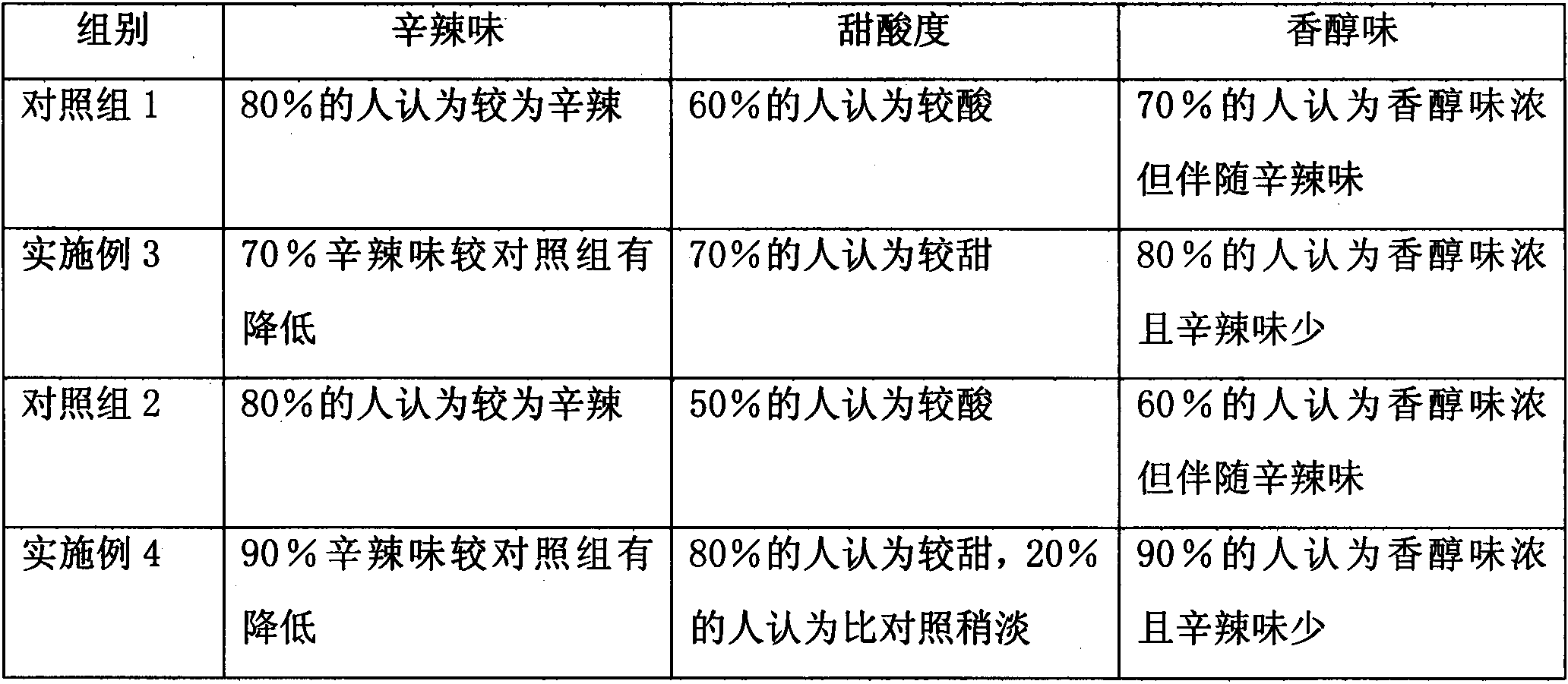

Examples

Embodiment 1

[0034] The experimental variety is crispy kumquat, which is characterized by the fact that the original fruit has a light spicy taste but less juice, and the core is often dry and hard. Fresh fruits are screened, cleaned, packed in film bags, and placed in a low temperature range of -5°C to 5°C for 2 months. Then adjust the temperature to 0.2°C to 52°C, and place the kumquat fruit at this temperature for 3 hours to get the frozen kumquat. During this period, the crispy kumquat fruit will suffer low temperature damage and induce low temperature damage degradation, as well as the spillage or leakage of essential oils. Volatile. Frozen kumquats are made into frozen kumquats after the whole peel of the crispy kumquats is frozen and the fruit body becomes soft. The prepared frozen kumquats become juicy, and the core tissue becomes soft without a tough feeling and remains crisp. The umami taste, sweet taste and golden yellow or yellow-green color of peeled kumquat. Then the prepar...

Embodiment 2

[0036] The experimental variety is crispy kumquat, which is characterized by the fact that the original fruit has a light spicy taste but less juice, and the core is often dry and hard. Fresh fruits are screened, cleaned, packed in film bags, and placed in a low temperature range from -3°C to -15°C for 6 days. Then adjust the temperature to 0.2°C to 15°C, and place the kumquat fruits at this temperature for 15 days to obtain frozen kumquats; Store at 15°C for 2 days. During this period, the crispy kumquat fruit occurred low temperature damage and induced low temperature damage degradation metabolism, as well as the spillover or volatilization of essential oils. Frozen kumquats are made into frozen kumquats after the whole peel of the crispy kumquats is frozen and the fruit body becomes soft. The prepared frozen kumquats become juicy, and the core tissue becomes soft without a tough feeling and remains crisp. The umami, sweetness and golden color of peeled kumquat. Then the ...

Embodiment 3

[0038]The experimental variety is Shouxing kumquat. The original fruit has more juice but a strong spicy taste, and the fruit is sour and hard and tough without slag. After the fresh fruit is screened, washed and packed in film, it is placed in a low temperature range of -3°C to 3°C for 30 days, so that the fruit of Shouxing Kumquat will be damaged by low temperature and induce the degradation and metabolism of low temperature damage. Transfer to an environment of 10°C to 25°C for 20 days to allow the fruit to undergo low-temperature damage, degradation, metabolism, and essential oil spillage or volatilization, until the peel of the whole fruit is multi-spotted or half-frozen, and the fruit body becomes soft. Serve as frozen kumquats. The skin and core of the frozen kumquats become soft, the sourness of the flesh and core decreases, the piquant taste of the skin becomes lighter, the umami taste is good, the amount of juice increases, and the skin is golden red. The prepared fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com